Application process of absorption article capable of preventing side leakage

A technology for absorbing articles and preventing side leakage, which is applied in the field of hygiene product production and can solve problems such as leakage prevention and side leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

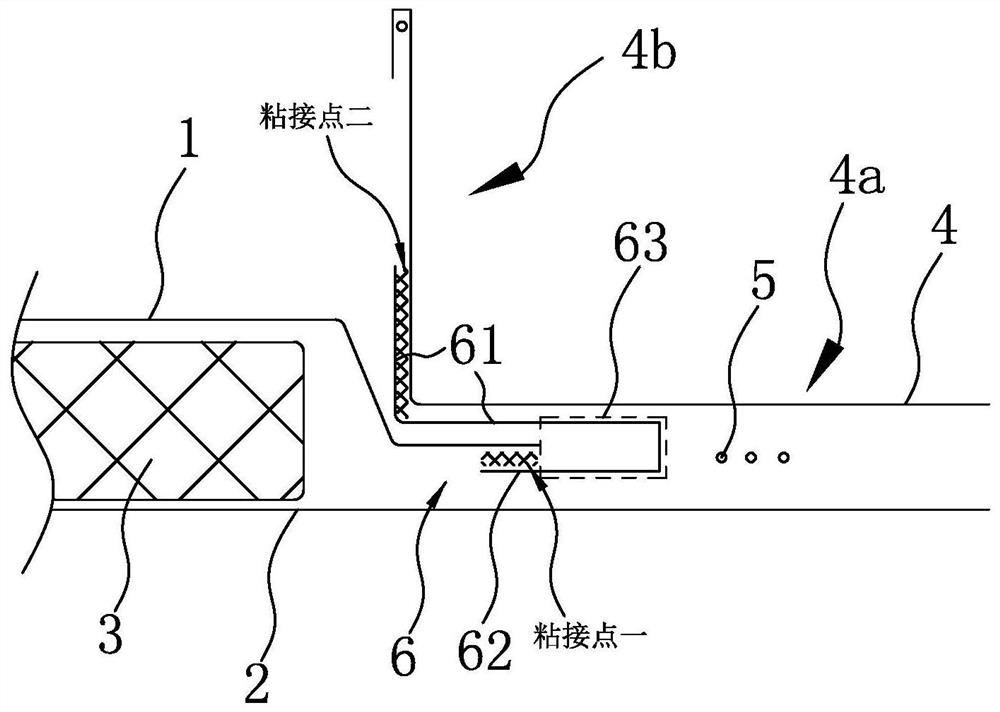

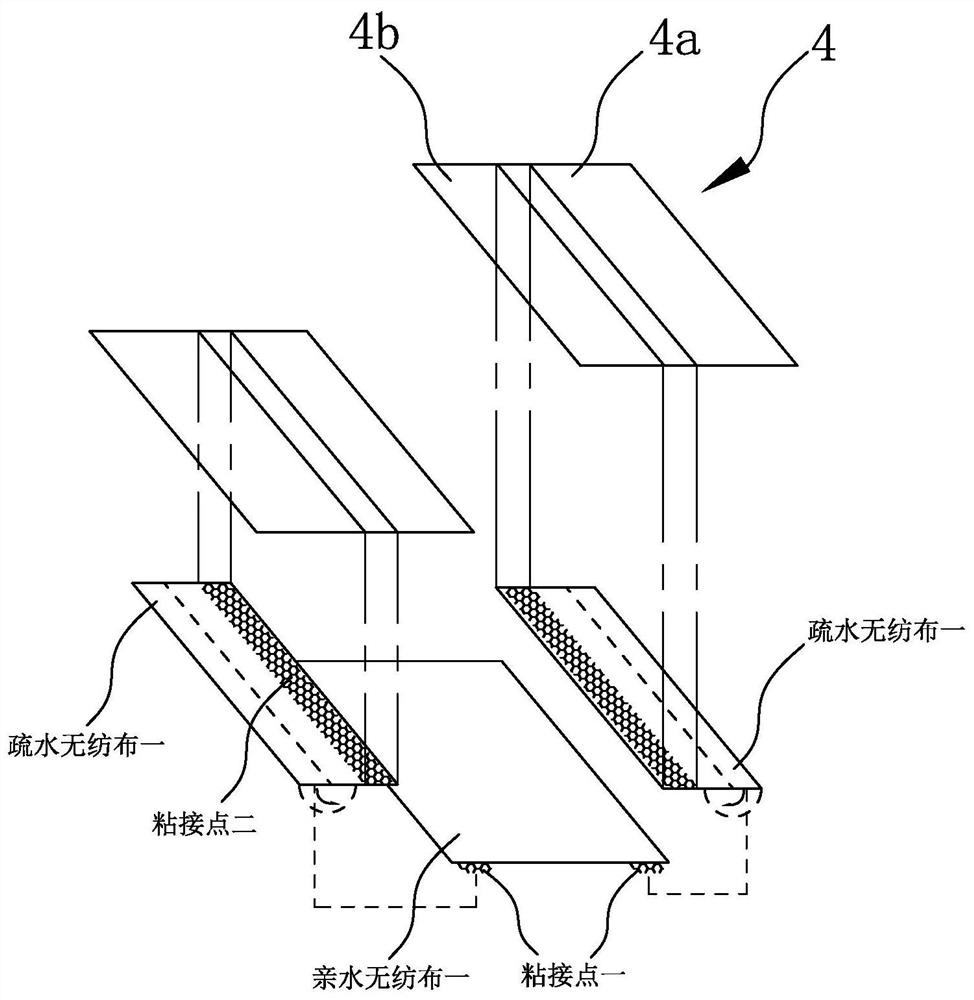

[0055] refer to figure 1 and figure 2 ,refer to figure 1 , an absorbent article preventing side leakage, comprising an absorbent article body (for the unfolded view of the absorbent article body, please refer to the applicant's prior application CN 202682192 U), the absorbent article body includes a liquid-permeable surface layer 1, The liquid-impermeable bottom layer 2, and the absorbent core 3 placed between the liquid-permeable surface layer 1 and the liquid-impermeable bottom layer 2, define that the main body of the absorbent article has a longitudinal direction in the length direction and a transverse direction in the width direction. Leak-proof partitions 4 extending longitudinally are arranged on both lateral sides of the main body, and the body of the absorbent article outside the lateral lateral ends of the liquid-permeable surface layer 1 is provided with leg circumference elastic stretch parts 5 extending longitudinally. Specifically, the elastically stretchable...

Embodiment 2

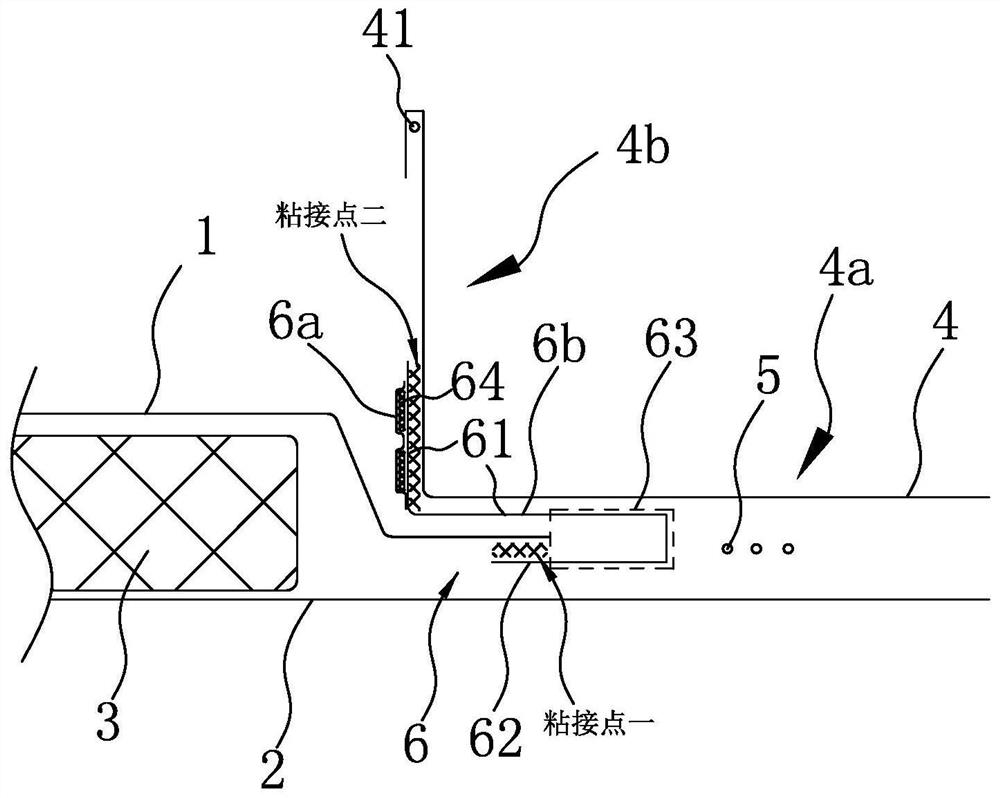

[0072] refer to image 3 and Figure 4 , compared with Embodiment 1, the above step b also includes:

[0073] Step b1, sizing glue on the lower end faces of the two hydrophobic non-woven fabrics and the end opposite to the bonding point 1 to form bonding point 3;

[0074] b2. A hydrophilic non-woven fabric 2 is arranged below the bonding point 3, and SAP is applied on the upper surface of the hydrophilic non-woven fabric 2 to form a side-absorbing core layer;

[0075] b3. Adhesively forming the product obtained in step b2 with the bonding point three.

[0076] In this embodiment, in the above step b2, the SAP on the partition absorbent core layer 64 is arranged at intervals along the lateral direction of the second hydrophilic non-woven fabric; specifically, the partition absorbent core layer 64 is arranged along the leak-proof partition 4. Two SAPs spaced laterally; different from Embodiment 1, the structure of the covering layer 6 of this embodiment is that the side attac...

Embodiment 3

[0079] refer to Figure 5 , Image 6 , compared with embodiment two, above-mentioned step b also comprises:

[0080] Step b1, sizing glue on the lower end faces of the two hydrophobic non-woven fabrics and the end opposite to the bonding point 1 to form bonding point 3;

[0081] b2. A hydrophilic non-woven fabric 2 is arranged below the bonding point 3, and SAP is applied on the upper surface of the hydrophilic non-woven fabric 2 to form a side-absorbing core layer 64;

[0082] b3. Adhesively forming the product obtained in step b2 with the bonding point three.

[0083] Specifically, in the above step b2, the SAP on the side absorbent core layer 64 is arranged at intervals along the lateral direction of the hydrophilic nonwoven fabric two; at the same time, in the above step b, the hydrophilic nonwoven fabric is located on the hydrophobic nonwoven fabric one. The lower end of the outer part of the cloth is applied with the elastic elastic parts 5 around the legs, and then i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com