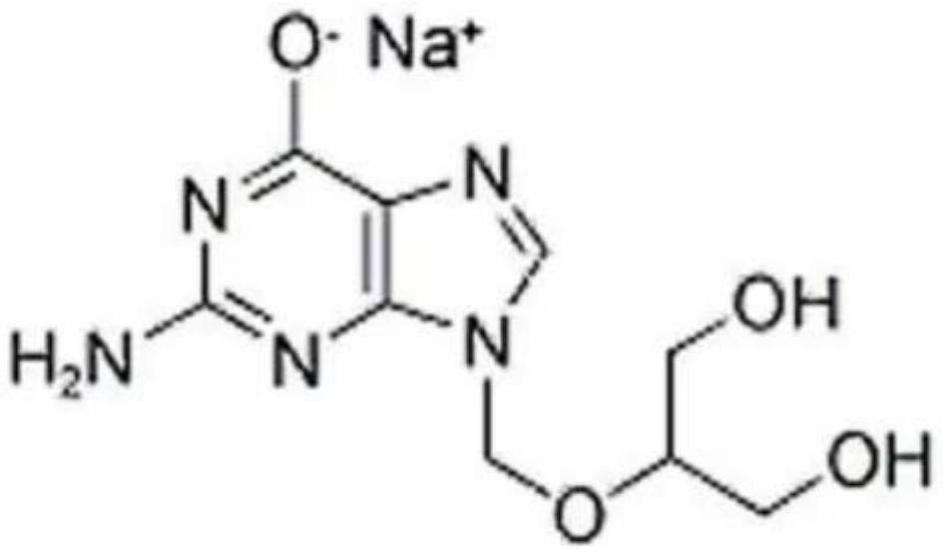

A kind of preparation method of ganciclovir sodium freeze-dried powder for injection

A technology of ganciclovir sodium and freeze-dried powder, which is applied in the field of medicine, can solve the problems of hygroscopicity and purity of ganciclovir or ganciclovir sodium freeze-dried powder, and achieve improved appearance and moisture absorption. Sexually low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

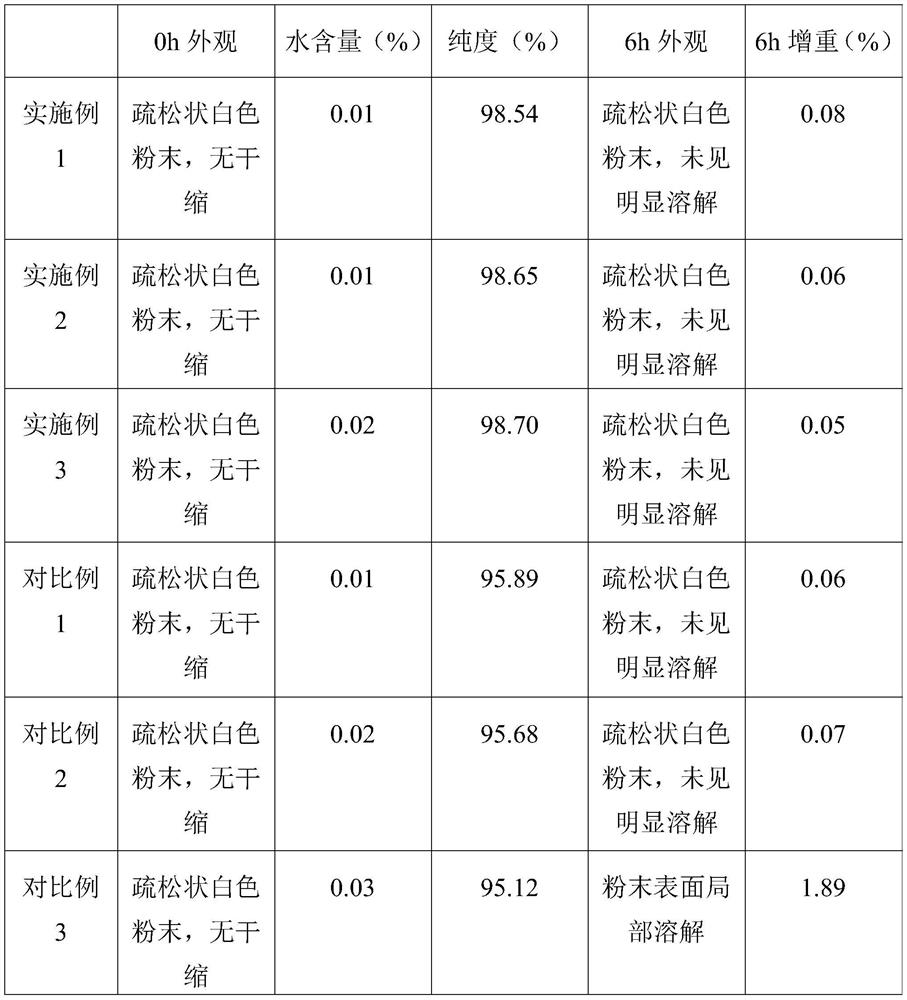

Embodiment 1

[0025] A preparation method of ganciclovir sodium freeze-dried powder for injection, comprising the following steps in turn:

[0026] (1) Add mannitol to water for injection to prepare mannitol solution. The mass concentration of the mannitol solution is 5%.

[0027] (2) adding activated carbon to the mannitol solution of step (1), stirring for 20min, standing for 15min, and then coarsely filtering and decarbonizing; passing the mannitol solution after coarsely filtering and decarbonizing through a 0.22 μm sterile mixed cellulose film to prepare A purified mannitol solution was obtained. The mass concentration of the activated carbon in the mannitol solution is 0.05%. The weight ratio of the ganciclovir sodium to the mannitol solution is 0.010:1.

[0028] (3) adding ganciclovir sodium to the purified mannitol solution, and then passing a 0.22 μm sterile mixed cellulose film to prepare a ganciclovir sodium solution; the temperature of the ganciclovir sodium solution is contr...

Embodiment 2

[0032] A preparation method of ganciclovir sodium freeze-dried powder for injection, comprising the following steps in turn:

[0033] (1) Add mannitol to water for injection to prepare mannitol solution. The mass concentration of the mannitol solution is 2%.

[0034] (2) adding activated carbon to the mannitol solution of step (1), stirring for 30min, standing for 20min, and then coarsely filtering and decarbonizing; passing the mannitol solution after coarsely filtering and decarbonizing through a 0.22 μm sterile mixed cellulose film to prepare A purified mannitol solution was obtained. The mass concentration of the activated carbon in the mannitol solution is 0.1%. The weight ratio of the ganciclovir sodium to the mannitol solution is 0.020:1.

[0035] (3) adding ganciclovir sodium to the purified mannitol solution, and then passing a 0.22 μm sterile mixed cellulose film to prepare a ganciclovir sodium solution; the temperature of the ganciclovir sodium solution is contro...

Embodiment 3

[0039] A preparation method of ganciclovir sodium freeze-dried powder for injection, comprising the following steps in turn:

[0040] (1) Add mannitol to water for injection to prepare mannitol solution. The mass concentration of the mannitol solution is 4%.

[0041] (2) adding activated carbon to the mannitol solution in step (1), stirring for 25 minutes, leaving it to stand for 18 minutes, and then coarsely filtering and decarbonizing; passing the mannitol solution after coarse filtering and decarbonizing through a 0.22 μm sterile mixed cellulose film to prepare A purified mannitol solution was obtained. The mass concentration of the activated carbon in the mannitol solution is 0.07%. The weight ratio of the ganciclovir sodium to the mannitol solution is 0.015:1.

[0042] (3) adding ganciclovir sodium to the purified mannitol solution, and then passing a 0.22 μm sterile mixed cellulose film to prepare a ganciclovir sodium solution; the temperature of the ganciclovir sodiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com