Environment-friendly coking waste gas treatment device

A waste gas treatment device and waste gas treatment technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of poor contact effect between coking waste gas and absorption liquid, inconvenient waste gas heat recovery, poor coking waste gas treatment effect, etc. problems, to achieve the effect of improving the exhaust gas treatment effect, improving the cooling effect, and increasing the exhaust gas treatment rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

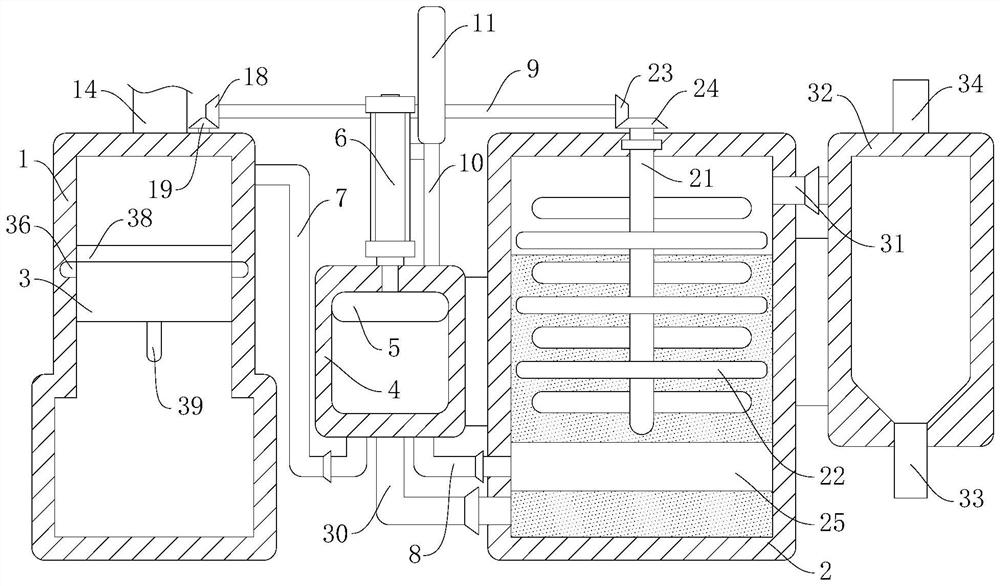

[0045] As an embodiment of the present invention, refer to figure 2 , the stirring mechanism includes a stirring rod 21 rotatably installed in the exhaust gas treatment box 2, and the top of the stirring rod 21 extends to the upper side of the exhaust gas treatment box 2, and a plurality of metal screens 22 are horizontally installed on the outer wall of the bottom end of the stirring rod 21 , the metal screen 22 can further reduce the bubbles generated by the exhaust gas in the absorption liquid, thereby facilitating the full contact between the exhaust gas and the absorption liquid, and the adjacent ends of the rotating rod 9 and the stirring rod 21 are respectively equipped with a third bevel gear 23 and a fourth bevel gear gear 24, and the third bevel gear 23 and the fourth bevel gear 24 mesh with each other.

[0046] The rotation of the rotating rod 9 can drive the third bevel gear 23, the fourth bevel gear 24 and the stirring rod 21 to rotate, and the rotation of the st...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap