Defective product crushing and recycling equipment for foamed plastic products

A foamed plastic and recycling equipment technology, applied in the direction of plastic recycling, mechanical material recycling, recycling technology, etc., can solve the problems of mechanical impact, impact on the surrounding environment, poor decomposition effect, etc., to reduce the possibility of blockage, guarantee Absorption effect, effect of improving usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

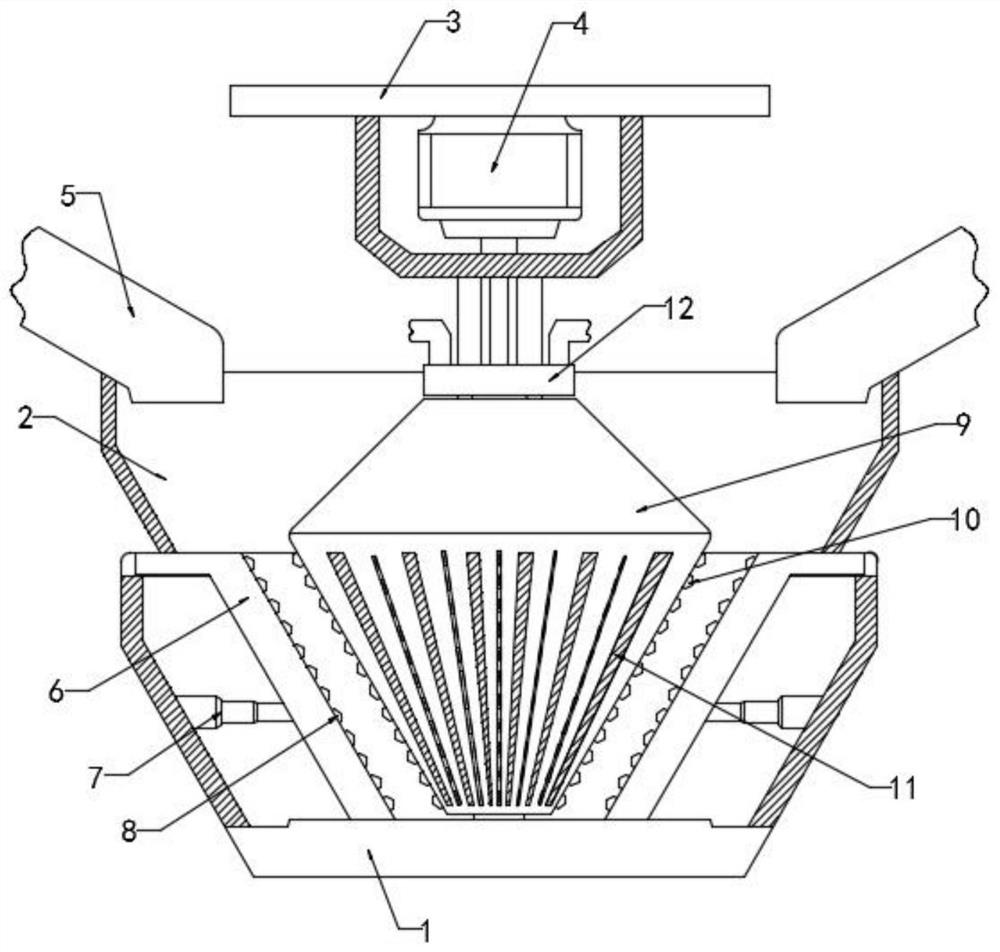

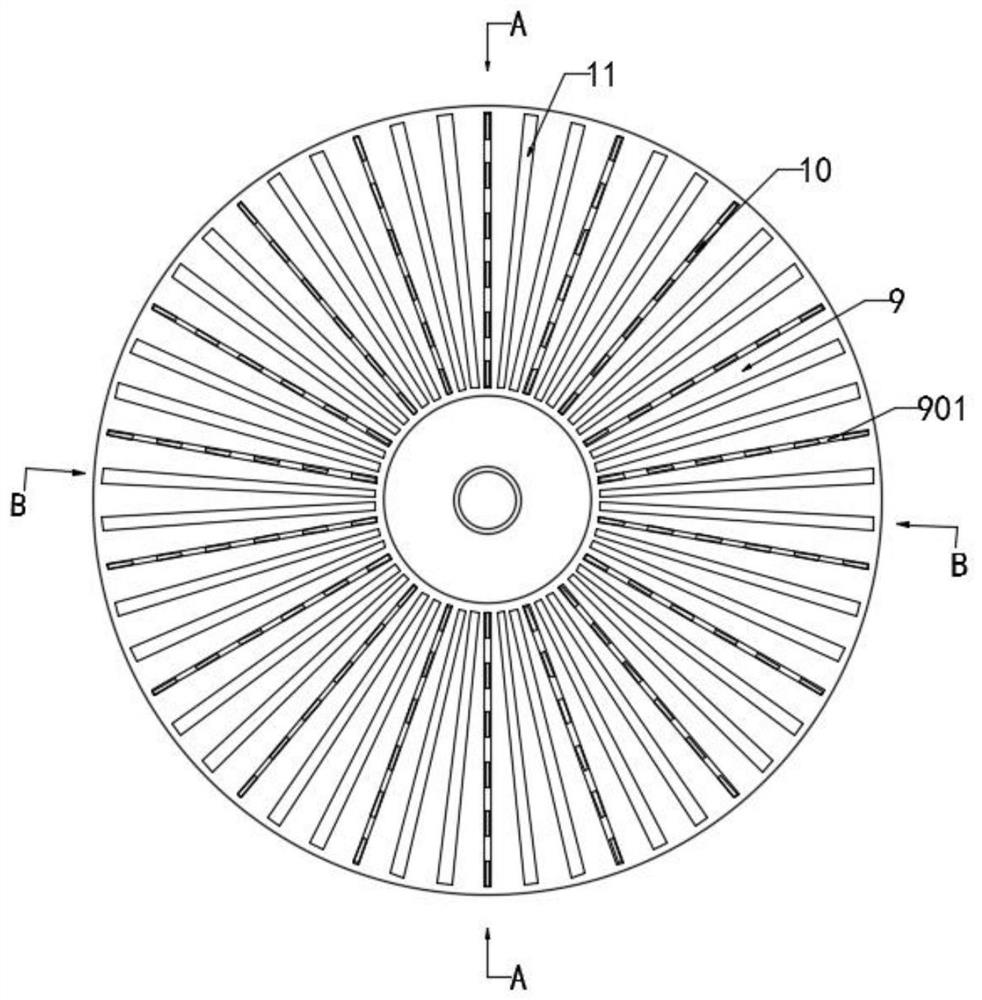

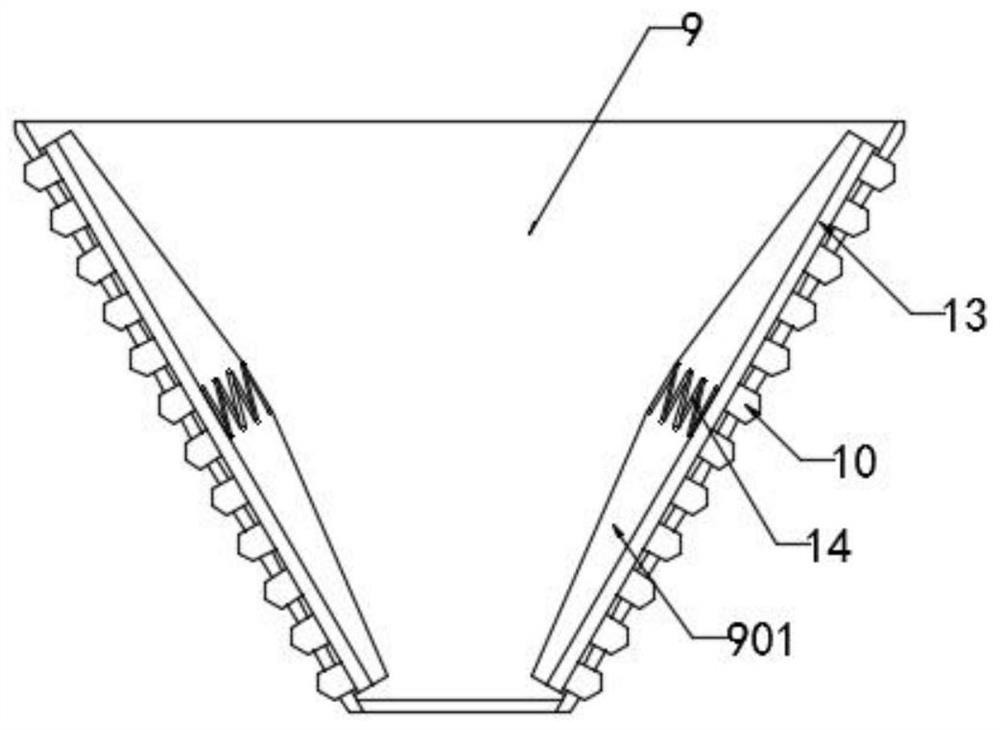

[0027] The following is attached Figure 1-5 The present invention is described in further detail.

[0028] The embodiment of the invention discloses a defective crushing and recycling device for foamed plastic products. refer to figure 1 and Figure 5 , a kind of crushing and recycling equipment for defective foamed plastic products, comprising a crushing disc 9, a transfer groove 2 is arranged coaxially on the outer top of the crushing disc 9, and a feeding pipe 5 is fixedly connected to the top of the transfer groove 2. The connection between the pipe 5 and the external feeding mechanism is convenient for materials to enter the transfer tank 2. The bottom end of the transfer tank 2 is in the shape of a circular table, and the outside of the bottom end of the crushing disc 9 is provided with a receiving disc 1, and the receiving disc 1 slides upwards. The sliding plate 6 is embedded with a ring array, the top of the sliding plate 6 is a horizontal structure, and the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com