Defoaming device and using method thereof

A gear pump and screw technology, applied in the field of defoaming device application and defoaming device, can solve the problems of rising product rejection rate, troubled rubber, affecting product quality, etc., and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] An embodiment of the present invention provides a defoaming device.

[0028] see figure 1 , figure 2 , image 3 with Figure 4 , including a bracket 16 and a moving bracket 7, the top of the bracket 16 is provided with a reduction motor 2, and one side of the reduction motor 2 is provided with a side pressure roller 3, and the top of the mobile bracket 7 is provided with a gear pump 11, between the side pressure roller 3 and the gear pump 11 Equipped with a degassing mechanism;

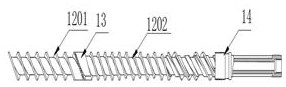

[0029] The degassing mechanism includes a barrel 5, a support collar is arranged outside the barrel 5, the support collar is fixedly connected to the top of the bracket 16, a temperature control device 1 is arranged inside the bracket 16, and the barrel 5 is arranged on the side pressure roller 3 and the gear pump 11 Between, screw rod 12 is arranged inside barrel 5, screw rod 12 comprises special-shaped screw rod 1201, exhaust screw rod 1202 and transition screw rod 13, transition screw r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com