Electrostatic chuck and method for eliminating residual electric charges of electrostatic chuck

An electrostatic chuck and residual charge technology, applied in the direction of holding devices, circuits, and electrical components that apply electrostatic attraction, can solve the problems of unable to take out the wafer, difficult to remove electrostatic charge, and prolong the production cycle, so as to improve stability and Product yield, elimination of sticking and chipping, and effects of shortening release time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

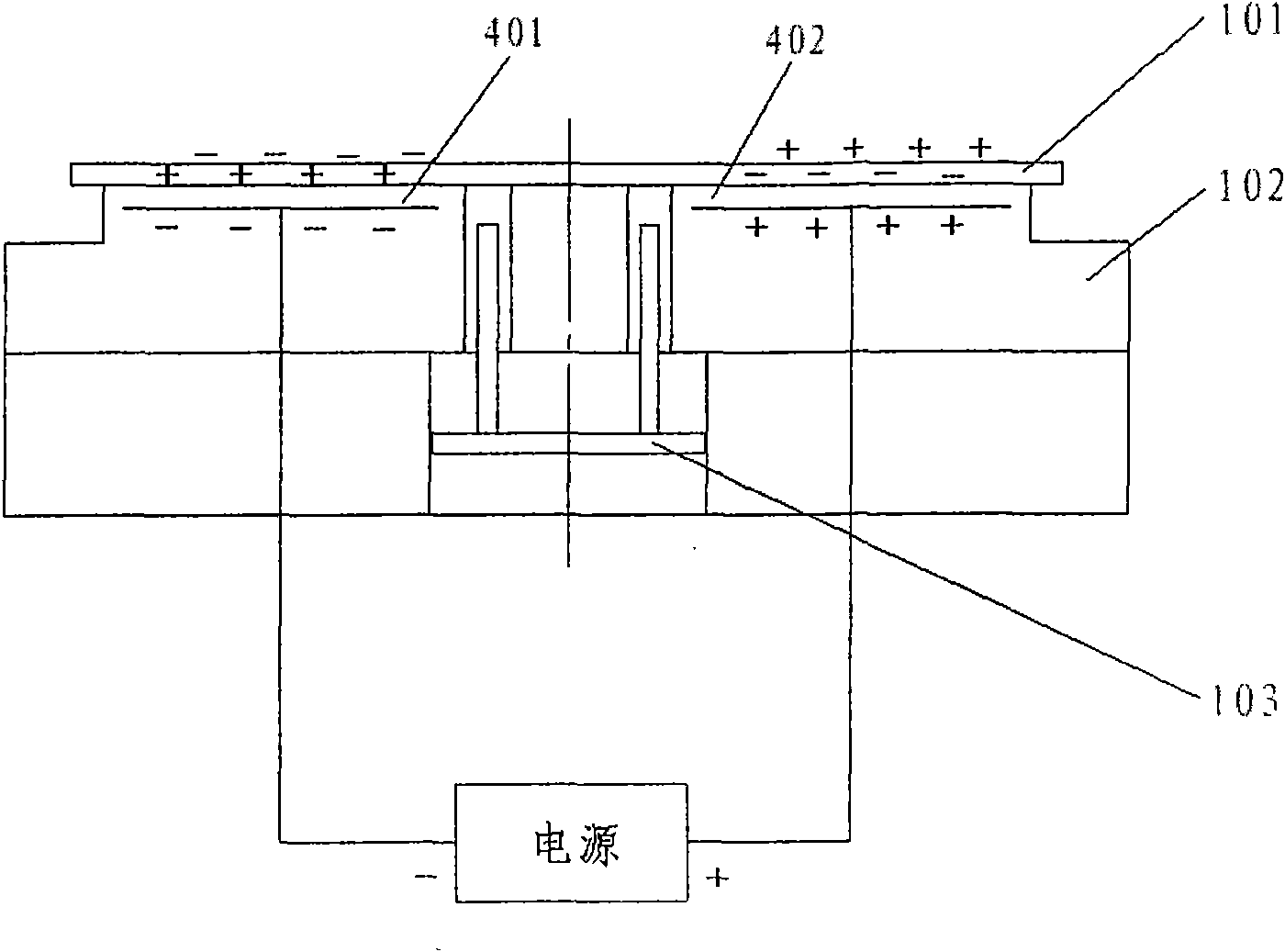

Embodiment 1

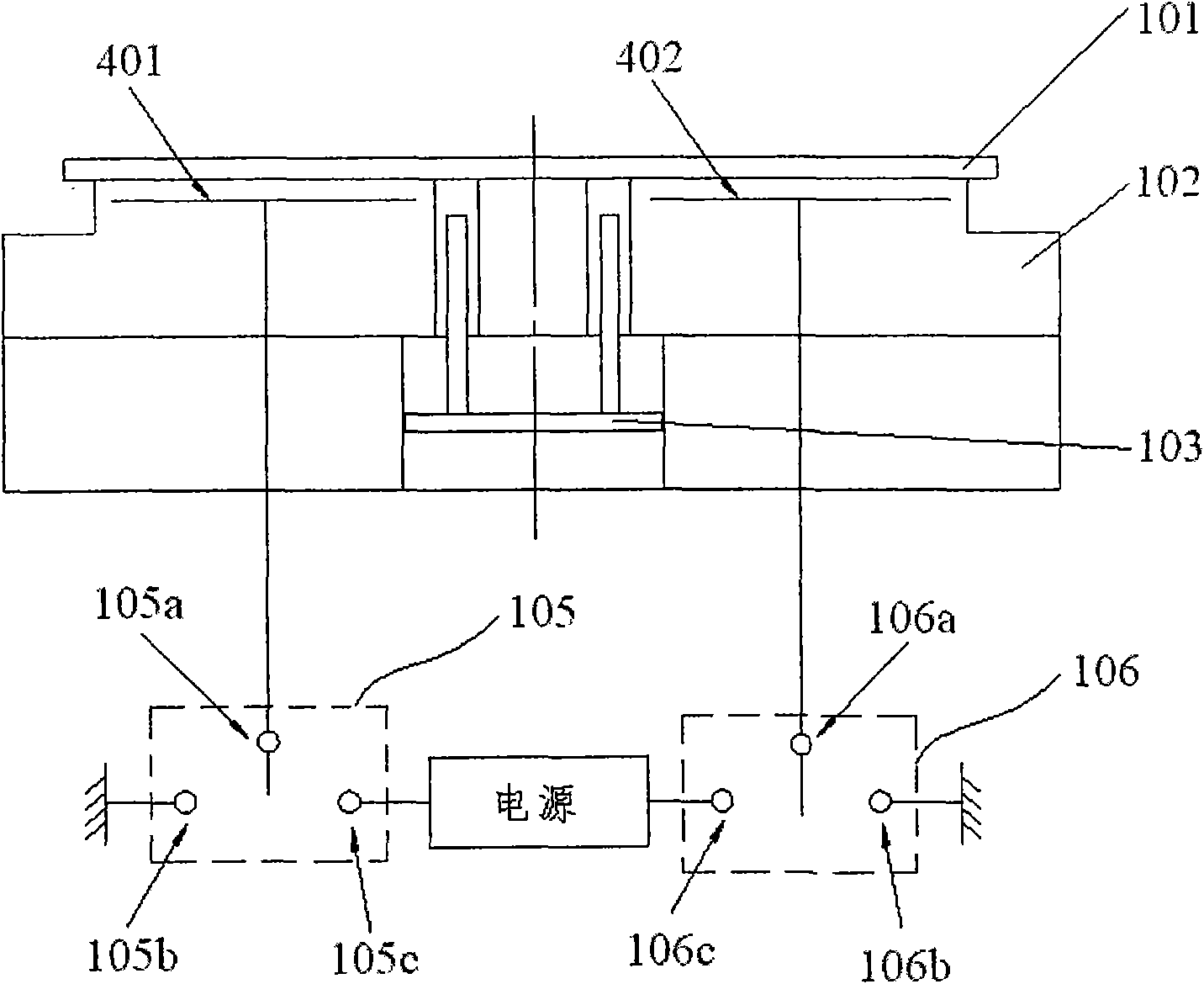

[0031] See figure 2 , is a structural schematic diagram of the electrostatic chuck provided by the present invention. As shown in the figure, the charge release unit in this embodiment uses a ground path to eliminate residual charges on the electrodes and the wafer. The electrostatic chuck of this embodiment includes a base 102, two electrodes 401, 402 (of course, the electrostatic chuck can also be provided with only one electrode), two transfer switches 105, 106 (the transfer switch is the part in the dotted line box in the figure , the following image 3 in the same way). The two electrodes 401 , 402 are separately arranged inside the base 102 and wrapped by an insulating layer (the insulating layer is not shown in the figure), and are respectively connected to the switches 105 , 106 arranged outside the base 102 . The middle part of the base 102 is provided with a passage through the base 102, and the wafer ejector pin 103 can move up and down in the passage.

[0032]...

Embodiment 2

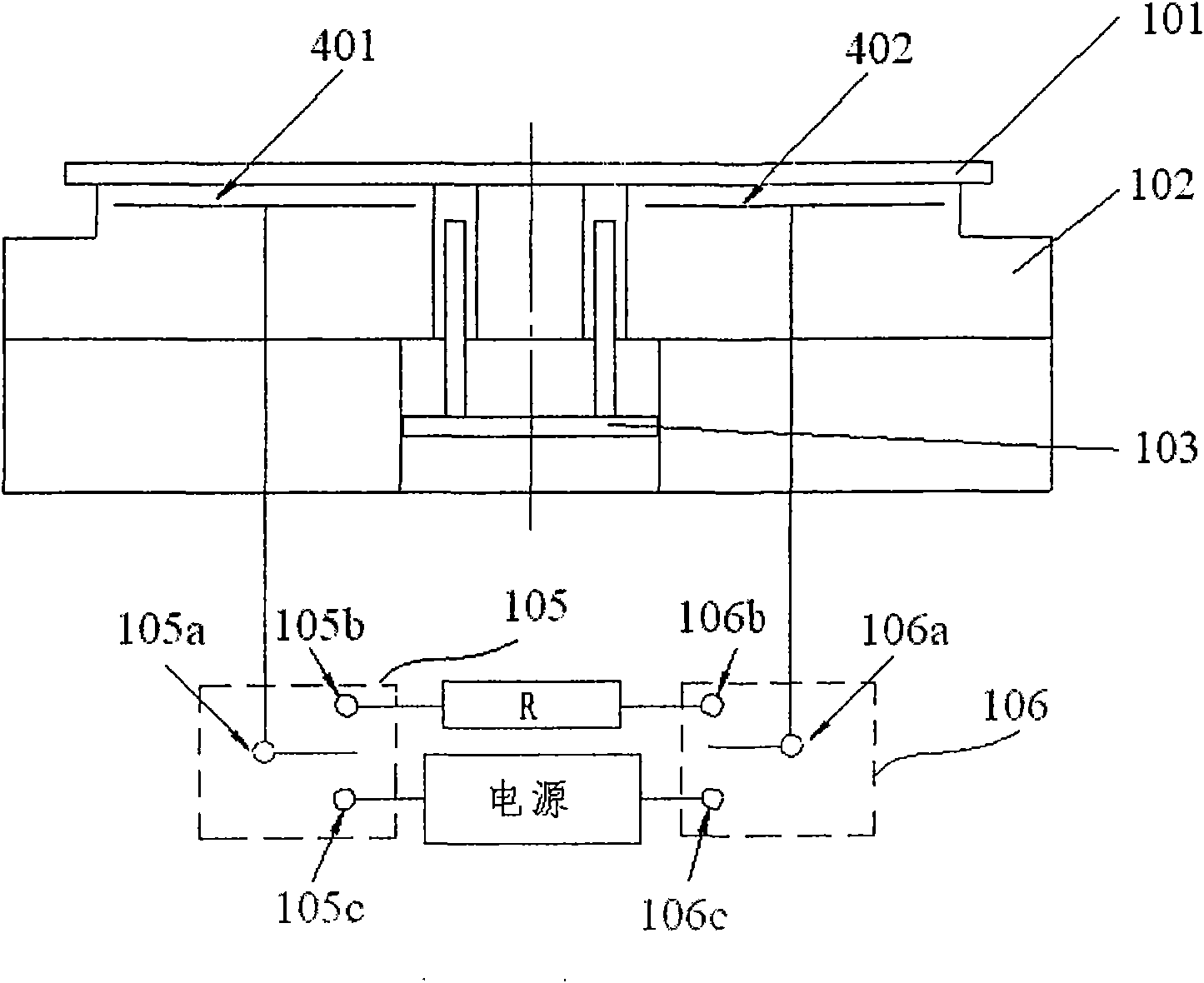

[0038] Another embodiment of the present invention provides an electrostatic chuck such as image 3 As shown, the charge release unit in this embodiment includes a resistor R, and the two electrodes 401 and 402 are connected by means of the resistor R to form a charge release circuit. Other than that, other structures of the electrostatic chuck in this embodiment are the same as those of the electrostatic chuck in Embodiment 1. In the following, only the differences between this embodiment and Embodiment 1 will be described.

[0039] Both ends of the resistor R are respectively connected to the first static contact 105b of the first transfer switch 105 and the first static contact 106b of the second transfer switch 106, that is to say, the first contact connected to the ground in Embodiment 1 The fixed contacts of the changeover switch 105 and the second changeover switch 106 are connected to the resistor R instead. Thus, the first electrode 401 and the second electrode 402 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com