Construction method of underground mass concrete steel formwork

A large-volume concrete and construction method technology, which is applied to the connection parts of formwork/formwork/work frame, formwork/formwork components, and basic structure engineering, etc., can solve the inconvenience of brick membrane construction methods, more labor and materials, Brick tire membrane deformation damage and other problems, to achieve good reinforcement effect, reduce engineering costs, easy production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The construction method of underground mass concrete steel formwork of the present invention comprises the following steps:

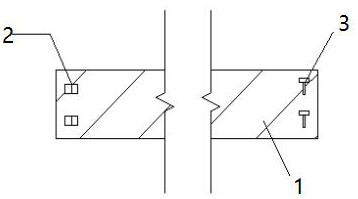

[0025] a. Customize a number of steel templates 1 and fixing parts 4, and two adjacent steel templates are connected and assembled by welding the bolt holes 2 and the bolt rods 3; figure 1 It is a schematic diagram of assembling adjacent steel formworks in the embodiment of the present invention.

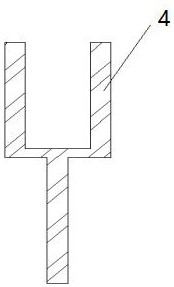

[0026] b. Pre-embed a number of fixing parts, the fixing parts are pre-buried vertically in the original soil layer, and a plain concrete cushion is poured on the original soil layer 6; figure 2 It is a structural schematic diagram of a fixing member according to an embodiment of the present invention. The fixing piece is a Y-shaped steel bar.

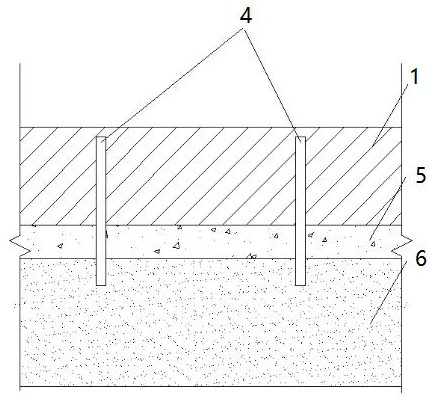

[0027] c. Connect the steel formwork together, fully weld the seams, and fix the steel formwork on the plain concrete cushion 5 with fixing pieces; image 3 It is a schematic diagram of steel formwork insta...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap