Wall-mounted wing wall combined with cast-in-place pile foundation pit supporting and construction method thereof

A technology of bored piles and foundation pit support, which is applied in foundation structure engineering, sheet pile walls, excavation, etc., can solve the problems of long construction period and high cost of foundation pit support engineering, achieve diversified construction methods, reduce Concrete waste and the effect of reducing the amount of earthwork excavation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

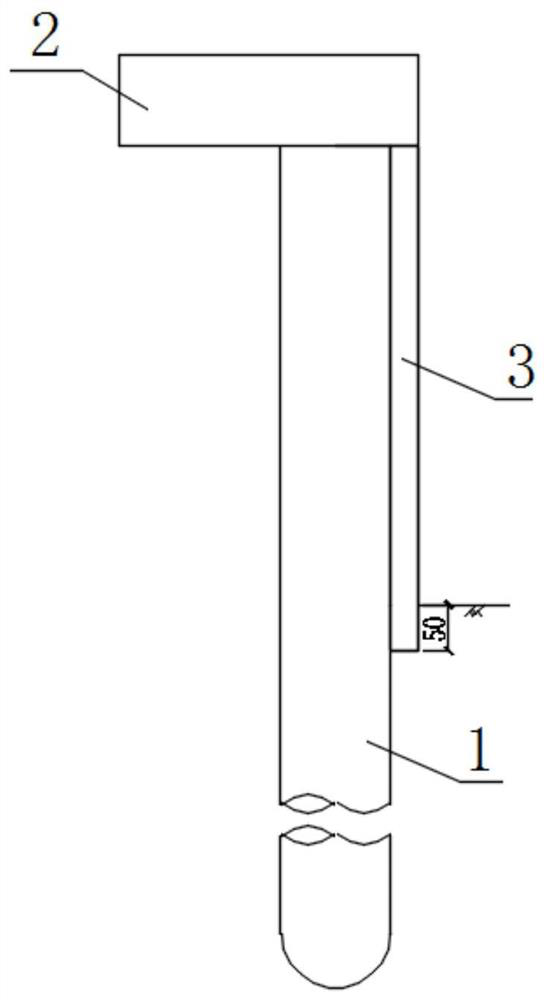

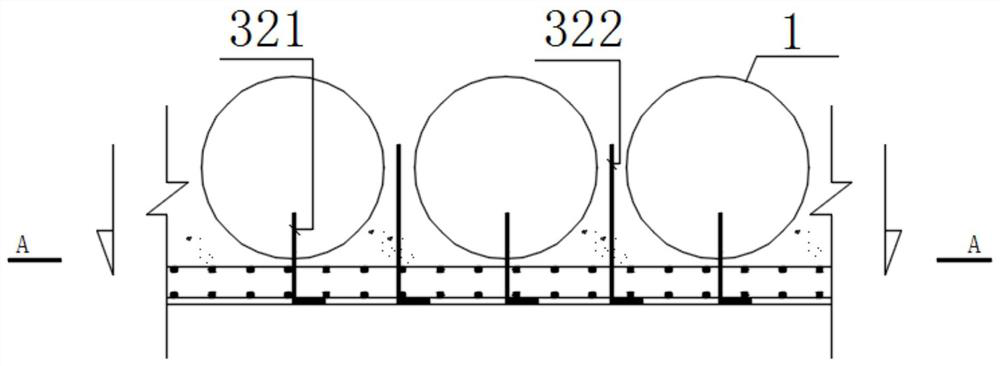

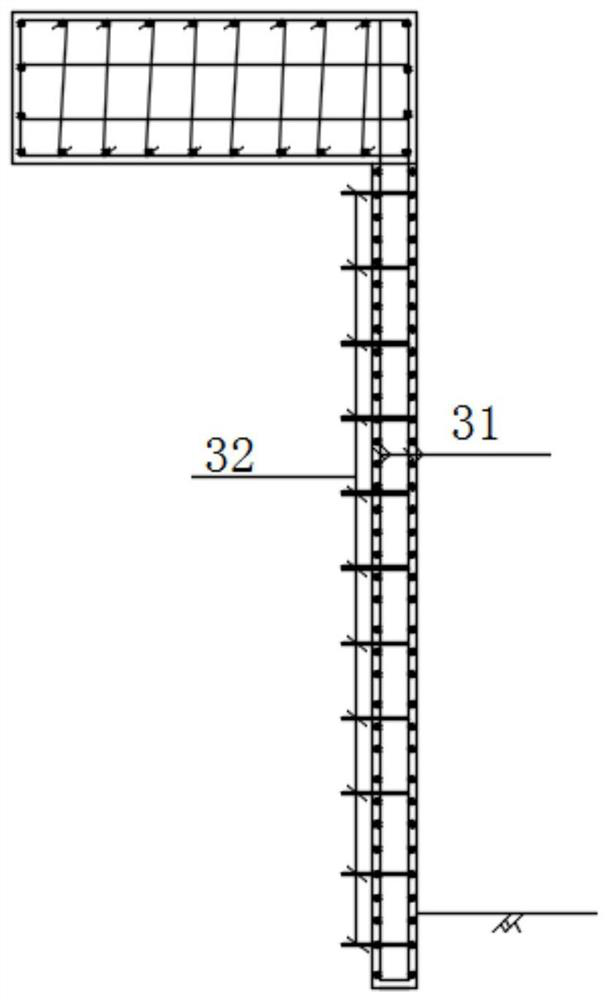

[0035] Such as Figure 1-4As shown, a wall-mounted wing wall combined with bored pile foundation pit support includes a pile 1 , a pile top platform 2 and a wall plate 3 . The wall plate 3 is located in front of the exposed surface of the cast-in-place pile 1, and the rear wall of the wall plate 3 is poured and connected with the exposed surface of the cast-in-place pile 1 to form an integrated structure, which is used as the main retaining and supporting structure of the wing wall. The pile top platform 2 is fixed on the top of the cast-in-place pile 1, and the pile top platform 2 is a cast body structure that is reinforced and reinforced on the basis of the original pile top crown beam and combined with the lower wall plate 3 as the upper support structure of the wing wall. Among them, the reinforcement is local supplementation and reinforcement of the internal reinforcement: in the vertical direction, new steel bars are newly installed at the front end of the original pile ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com