Construction method for karst tunnel to penetrate through deep gravel soil layer

A construction method and technology for tunnels, applied in tunnels, tunnel linings, earthwork drilling, etc., can solve problems such as easy deformation, unstable initial support, etc., and achieve vertical resistance, support effectiveness, and stress. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0040] This embodiment provides a construction method for a karst tunnel passing through a deep gravel soil layer, so as to improve the construction quality and ensure the reliability of the construction process during tunnel construction in the deep gravel soil layer.

[0041] First of all, the geological conditions should be detected according to the actual situation before construction to determine whether advance support is required. If advance support is required, the tunnel body should be excavated after the advance support is completed.

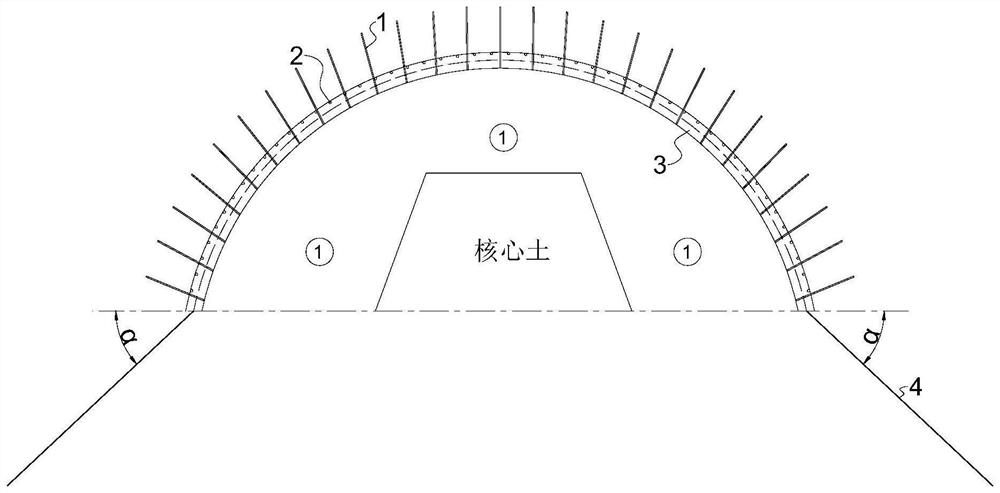

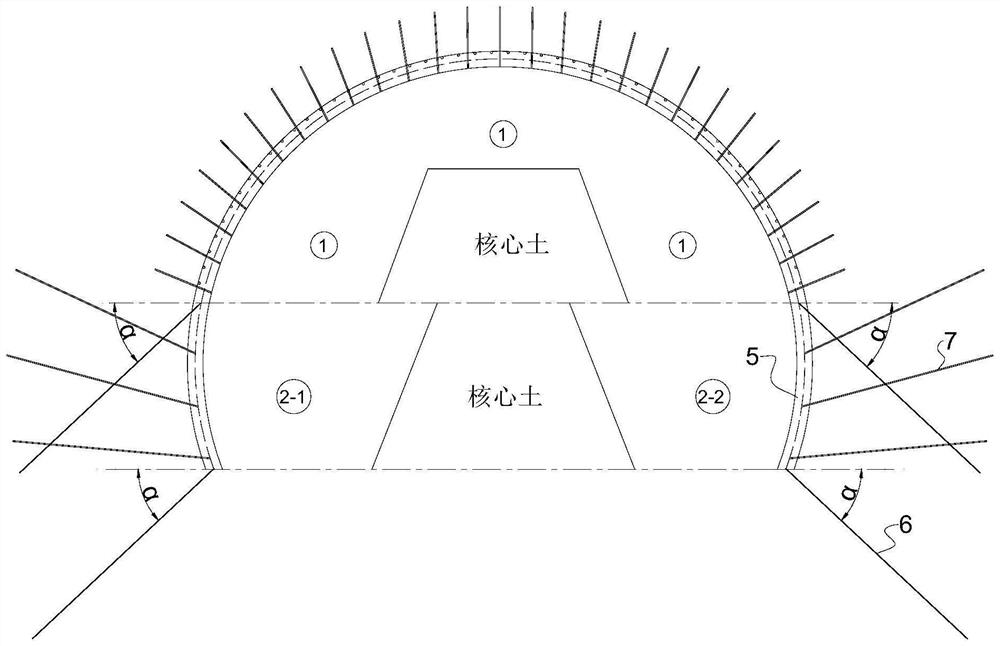

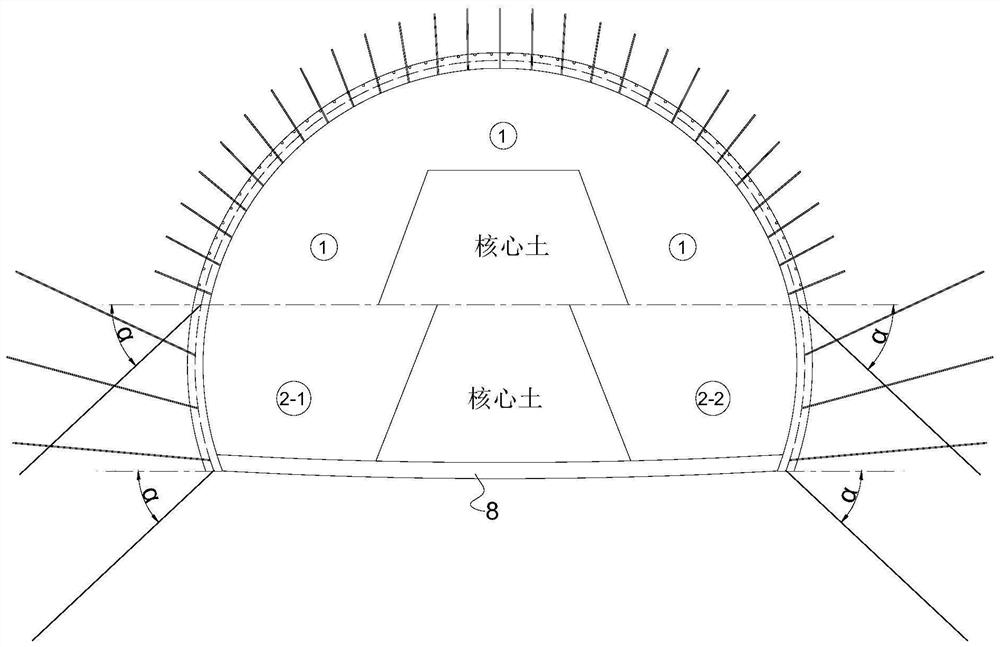

[0042] When advance support is required, advance support can be applied to the arch of the tunnel along the excavation direction of the tunnel. It should be noted that in order to improve the reliability of advance support, it provides more effective support for subsequent tunnel excavation. In the actual implementation of advance support, different measures are adopted for the advance support of the tunnel entrance section and the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spacing | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com