VOC tank cleaning instrument

A technology of can cleaner and suma can, applied in instruments, scientific instruments, cleaning hollow objects, etc., can solve the problems of inconvenience, single function, pollution, etc., and achieve the effect of convenient and reliable use, reasonable structure design, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

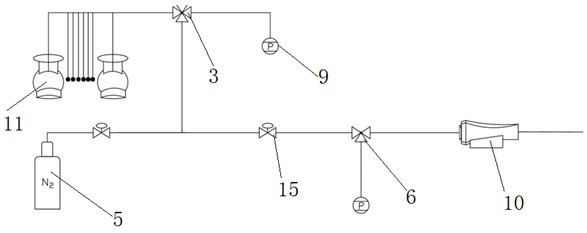

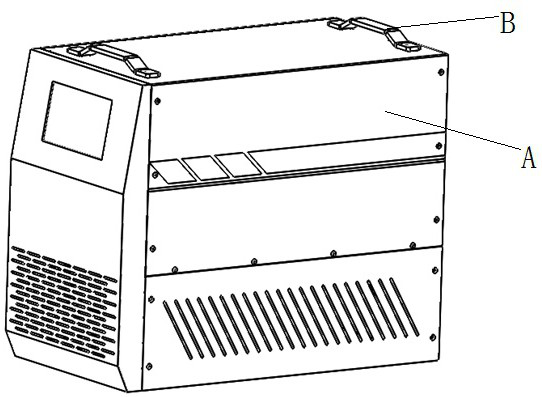

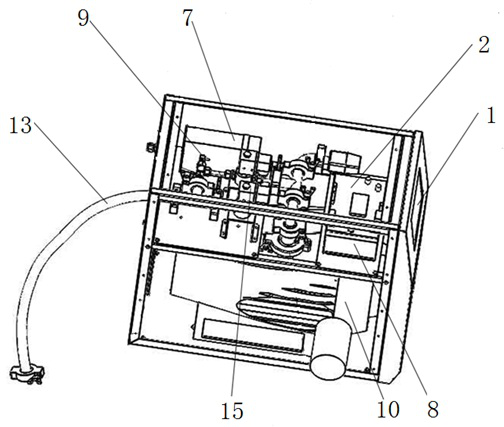

[0020] refer to Figure 1-3 , the present specific embodiment adopts the following technical solutions: VOC tank cleaning instrument, including a cabinet A, the side of the cabinet A is provided with a seven-inch screen 1, the main control circuit board 2 is arranged inside the cabinet A, and the main control circuit board 2 It is connected to the controller 7, the controller 7 is connected to the pressure sensor 9, the pressure sensor 9 is connected to the four-position four-way valve 3, and the four-position four-way valve 3 is connected to multiple suma tanks through the suma tank connecting pipe 13 and the clamp 4 11 connected, the four-position four-way valve 3 is connected with the nitrogen cylinder 5 and the three-position three-way valve 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com