Radioactive metal reconditioning device and radioactive metal treatment system and method

A metal processing and radioactive technology, which is applied in the field of radioactive metal conditioning devices, can solve the problems of low space utilization rate, long time consumption, and inability to meet size and length requirements of charging barrels, and achieves increased space utilization rate, rapid and effective crushing and compression. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

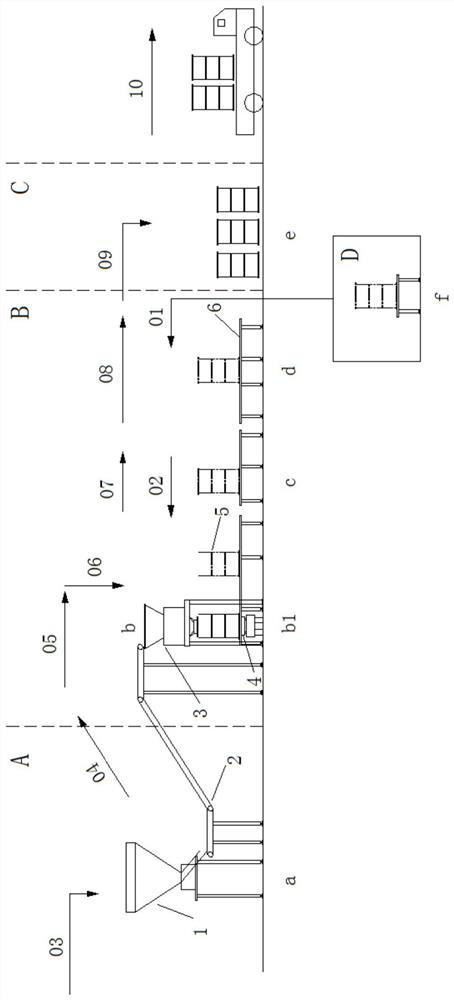

[0059] This embodiment discloses a radioactive metal preparation device, such as figure 1As shown, it includes crushing unit, transport unit and capping unit, all of which are set in preparation area B. Wherein, the crushing unit includes a crusher 3, which is set at the crushing station in the preparation area B, and is used for crushing and compressing radioactive metals.

[0060] In this embodiment, the crusher 3 can usually crush the radioactive metal into fragments with a size of 10-50 mm. In addition, the crusher 3 also has a compression effect on the pipes, profiles, etc. in the radioactive metal. In this embodiment, the crushing The machine 3 adopts a double-shaft crusher, and its compression ratio to the pipeline can reach more than 90%, which can greatly reduce the volume of radioactive metals and improve the utilization rate of the inner space of the charging barrel 4. Of course, the crusher 3 can also use an impact crusher, a gyratory crusher or other crushers cap...

Embodiment 2

[0097] This embodiment discloses a radioactive metal processing system, including a feeding device, and also includes the radioactive metal preparation device in Embodiment 1, wherein the feeding device includes a vibrator 1 and a conveyor belt, and the feeding device includes a vibrator 1 and a conveyor belt 2, and the vibrator 1 is set in the receiving area A, and is used for uniform feeding of the received radioactive metal.

[0098] The conveyor belt 2 is arranged between the discharge port of the vibrator 1 and the feed port of the crusher 3, and is used for conveying the discharged radioactive metal.

[0099] In this embodiment, the radioactive metal processing system further includes a crane and a storage container, wherein the storage container is set in the temporary storage area C, and is used to store the charging barrel 4 after packaging the debris.

[0100] Among them, receiving area A and temporary storage area C are adjacent to preparation area B respectively. ...

Embodiment 3

[0107] This embodiment discloses a radioactive metal treatment method, which can be used in the radioactive metal treatment system of Example 2, and the method includes the following steps:

[0108] Carry out blanking of radioactive metals, and transport the unloaded material to the crusher 3 on the crushing station for crushing, and place the empty charging barrel 4 on the barrel feeding station f of the barrel feeding area D, and then Transport it to the barrel loading station in the preparation area B, and then put the broken material obtained after being crushed by the crusher 3 into the barrel 4 .

[0109] Specifically, as shown in process 03, the radioactive metal is grasped, transported or dumped into the vibrator 1 in the receiving area A, and the radioactive metal is transferred from the vibrator 1 to the conveyor belt 2 .

[0110] As shown in process 04, the radioactive metals are transported to the staging area B via the conveyor belt 2.

[0111] As shown in proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com