Air cap spraying and drying device and method

A technology of drying device and hood, which is applied in the direction of spraying device, device for coating liquid on the surface, coating, etc. It can solve the problems of affecting human health, low working efficiency, poor spraying effect, etc., and achieve novel overall structure and high production efficiency. High efficiency and fewer operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

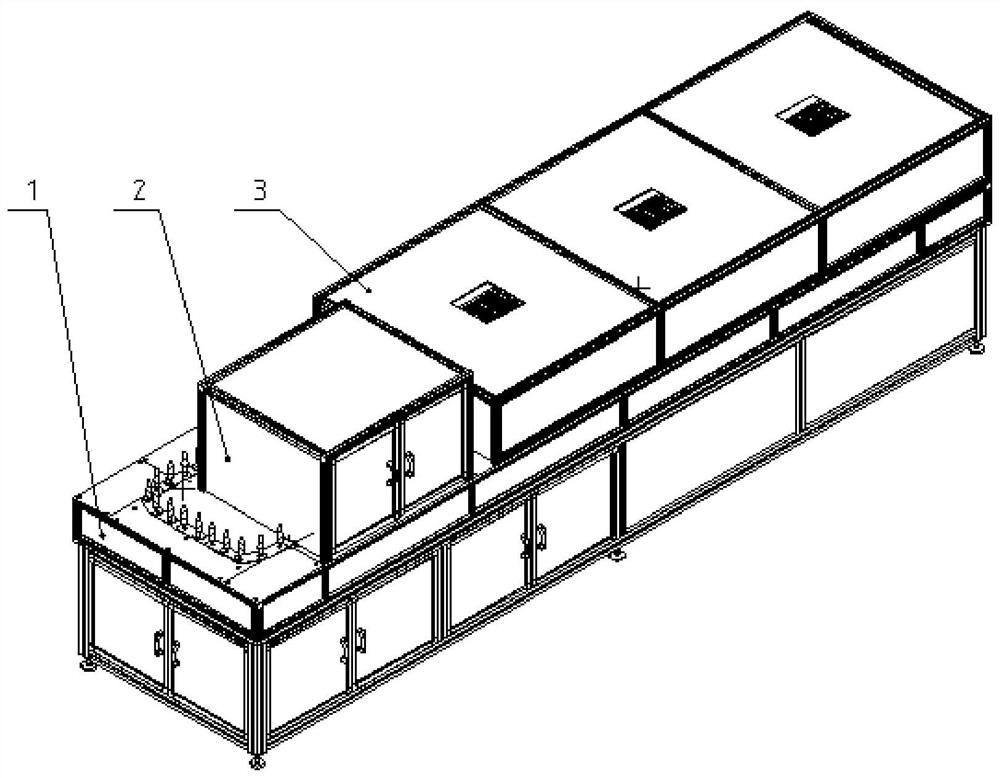

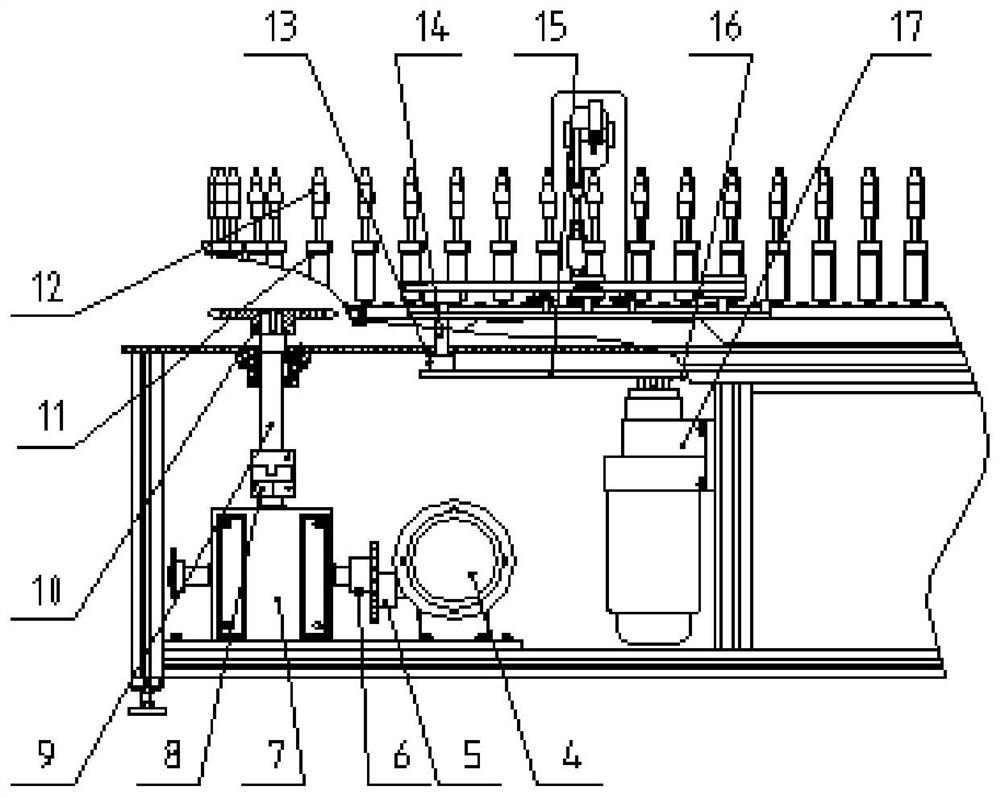

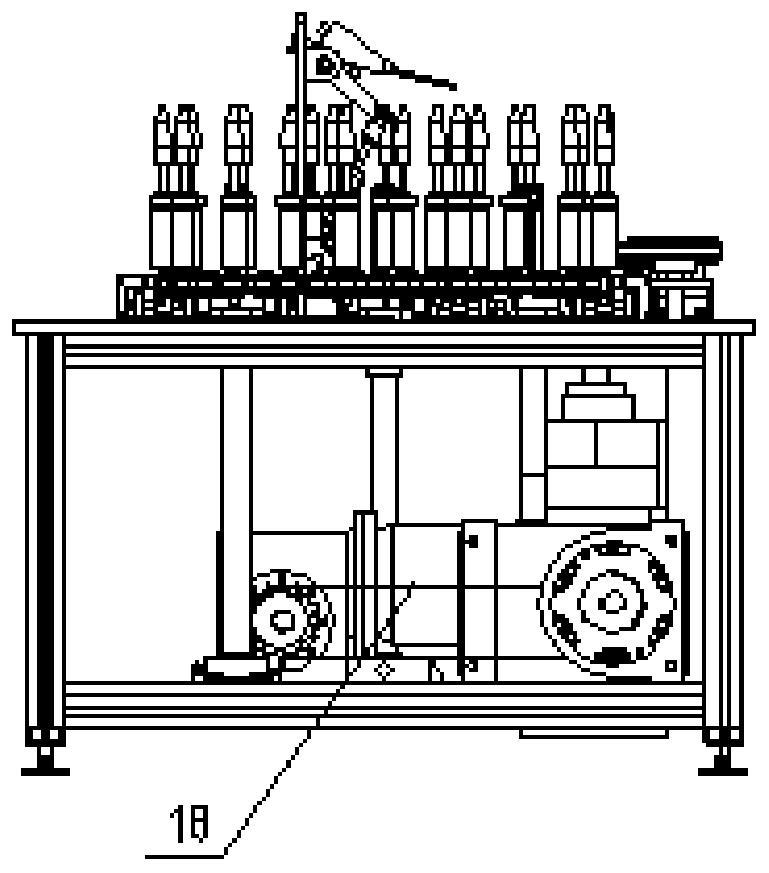

[0027] Example 1: Please also see figure 1 , 2 , 3, 4, 5, 6, 7, 8, the hood spray drying device of the present invention comprises a frame 1, an anti-paint cover 2, a heat preservation cover 3, a No. 1 reducer 4, a driving sprocket 5, and a driven sprocket 6 , splitter 7, coupling 8, drive shaft 9, drive sprocket 10, turntable 11, hood 12, driven pulley 13, rotating shaft 14, belt 15, drive pulley 16, No. 2 reducer 17, Chain 18, special chain 19, spraying mechanism 20, transmission belt 21, large pulley 22, drier 23. Among them, the No. 1 reducer 4, driving sprocket 5, driven sprocket 6, splitter 7, coupling 8, transmission shaft 9, transmission sprocket 10, rotary tool 11, chain 18, and special chain 19 constitute The transmission mechanism realizes the transmission of the hood. Described driven pulley 13, rotating shaft 14, belt 15, driving pulley 16, No. 2 speed reducer 17, transmission belt 21, large pulley 22 form hood rotation mechanism.

[0028] Wherein, the No. 1 r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com