Series-parallel oil-electric hybrid driving device suitable for commercial vehicle

A hybrid drive and hybrid technology, applied in the direction of power plant, hybrid vehicle, air pressure power plant, etc., can solve the problems of short cruising range, difficult charging, etc., achieve low power demand, increase cruising range, and improve transmission efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

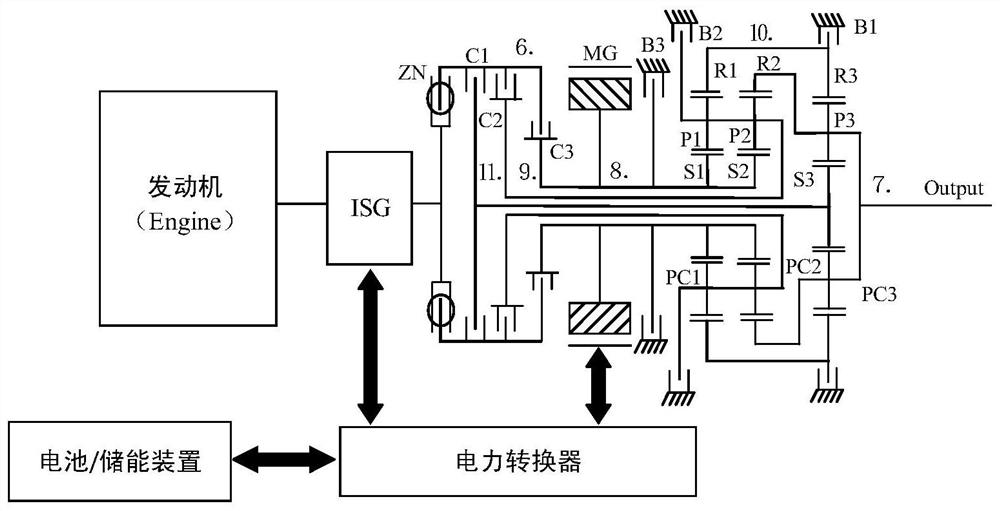

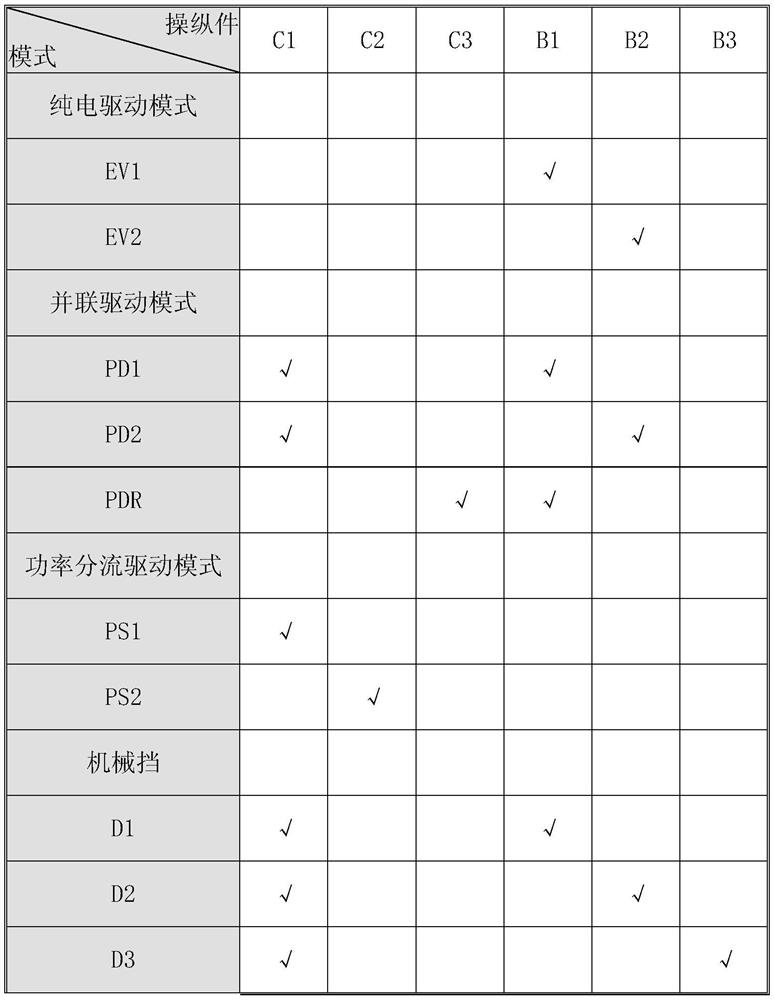

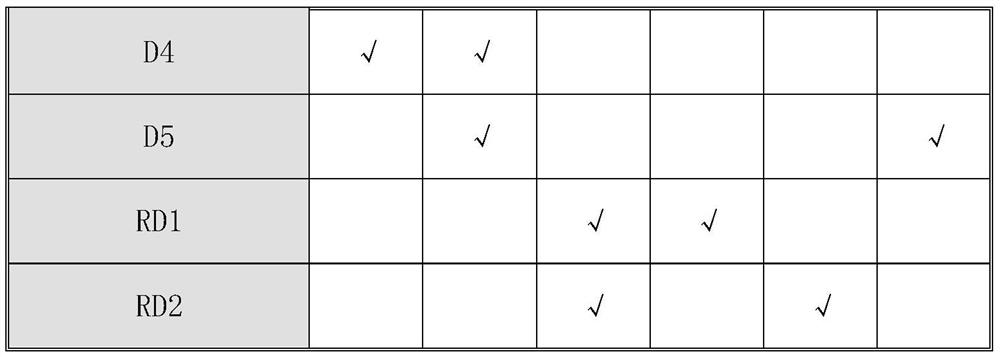

[0076] In order to solve the problems existing in the prior art, the technical solution to realize this embodiment is as follows figure 1 As shown, this figure describes the specific scheme of the hybrid drive device, which consists of an engine, two motors, three planetary rows, three clutches and three brakes to achieve pure electric low-speed start, series drive, parallel drive, and hybrid drive And fixed mechanical gear and other modes.

[0077] For the convenience of description, the rotating parts are defined in turn as follows: ①—the engine Engine and the output shaft of the first motor ISG are connected to the outer hub of the clutch C1, the outer hub of the clutch C2, and the outer hub of the clutch C3 through the damper ZN, ②—the output shaft Output And the second row of ring gear R2 and the third row of planet carrier PC3, ③—the output shaft of the second motor MG and the inner hub of clutch C3 and the inner hub of brake B3, one row of sun gear S1 and the second row...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com