Self-repairing rubber composition for tires and preparation method of self-repairing rubber composition

A rubber composition and self-repairing technology, applied to used vulcanized rubber adhesives, other rubber adhesives, waste rubber adhesives, etc., can solve the problem of affecting tire balance performance, poor flow sealing effect, and non-recyclable And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

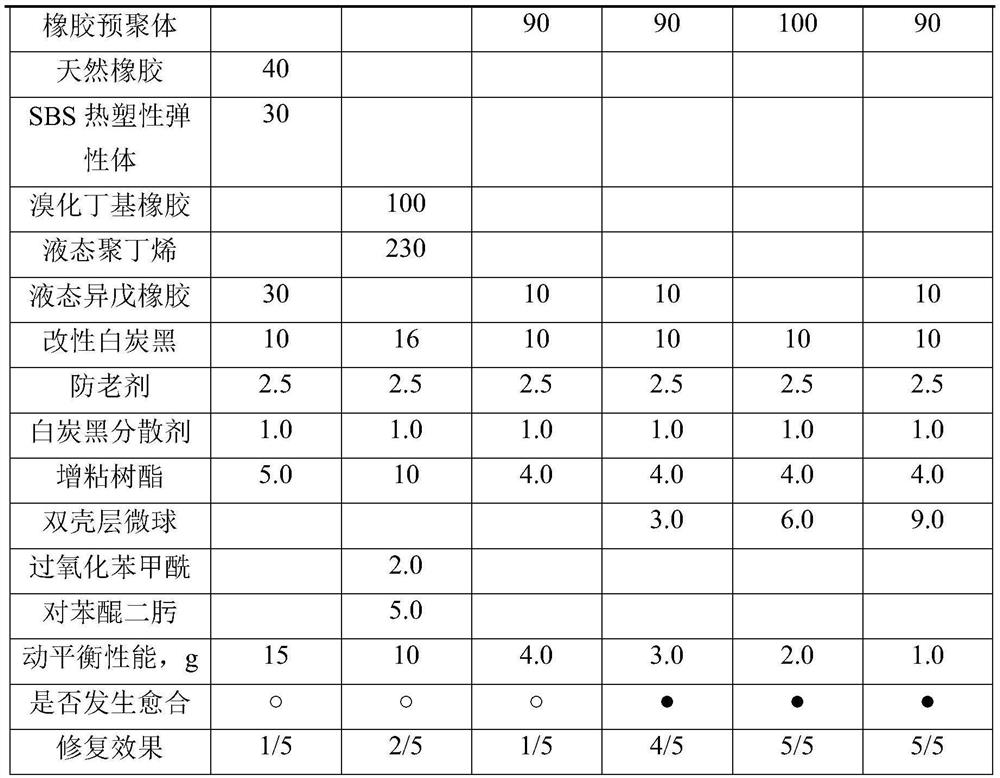

[0045] 90 parts of reverse vulcanized rubber prepolymer, 10 parts of liquid isoprene rubber, 3.0 parts of silica-gel-catalyzed repair polymer double-shell microspheres, 2.5 parts of anti-aging agent, 10 parts of modified white carbon black, white carbon 1.0 parts of black dispersant, 4.0 parts of tackifying resin. The specific formula is shown in Table 1.

[0046] Self-healing rubber composition preparation process:

[0047] A mix of:

[0048] 1) Set the temperature of the reactor at 160°C and the stirring speed at 70rpm, add the rubber prepolymer and liquid isoprene rubber into the reactor, and add anti-aging agent into the reactor at the same time, stir and mix for 4 minutes;

[0049] 2) Put the modified silica, the silica dispersant, and the tackifying resin into the reaction kettle, and stir and mix for 5 minutes to obtain a mixed rubber composition.

[0050] Two stage mixing:

[0051] 3) Add the rubber composition glue prepared in step 2) into a reaction kettle with a...

Embodiment 2

[0057] Using 100 parts of reverse vulcanized rubber prepolymer, 6.0 parts of silica-gel-catalyzed repair polymer double-shell microspheres, 2.5 parts of anti-aging agent, 10 parts of modified silica, 1.0 parts of silica dispersant, increasing 4.0 parts of sticky resin. The specific formula is shown in Table 1.

[0058] Self-healing rubber composition preparation process:

[0059] A mix of:

[0060] 1) Set the temperature of the reactor at 160°C and the stirring speed at 70rpm, add the reverse vulcanized rubber prepolymer into the reactor, and at the same time add the anti-aging agent into the reactor, and stir and mix for 4 minutes;

[0061] 2) Put the modified silica, the silica dispersant, and the tackifying resin into the reaction kettle, and stir and mix for 5 minutes to obtain a mixed rubber composition.

[0062] Two stage mixing:

[0063] 3) Add the rubber composition glue prepared in step 2) into a reaction kettle with a temperature controlled at 120°C and a rotatio...

Embodiment 3

[0069] Using 90 parts of reverse vulcanized rubber prepolymer, 10 parts of liquid isoprene rubber, 9.0 parts of silica-gel-catalyzed repair polymerizer double-shell microspheres, 2.5 parts of anti-aging agent, 10 parts of modified white carbon black, white carbon 1.0 parts of black dispersant, 4.0 parts of tackifying resin. The specific formula is shown in Table 1.

[0070] Self-healing rubber composition preparation process:

[0071] A mix of:

[0072] 1) Set the temperature of the reactor at 160°C and the stirring speed at 70rpm, add the reverse vulcanized rubber prepolymer and liquid isoprene rubber into the reactor, and add anti-aging agent into the reactor at the same time, and stir and mix for 4 minutes;

[0073] 2) Put the modified silica, the silica dispersant, and the tackifying resin into the reaction kettle, and stir and mix for 5 minutes to obtain a mixed rubber composition.

[0074] Two stage mixing:

[0075] 3) Add the rubber composition glue prepared in step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com