Method for refining sheep tail oil by using biological enzyme method

A biological enzyme method, sheep tail oil technology, applied in the production of fat, fat oil/fat production, fat oil/fat refining, etc., can solve the problems of perishable extraction, incompleteness, easy discoloration, etc., and achieve low cost and oil yield. The effect of high, low amount of enzyme

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

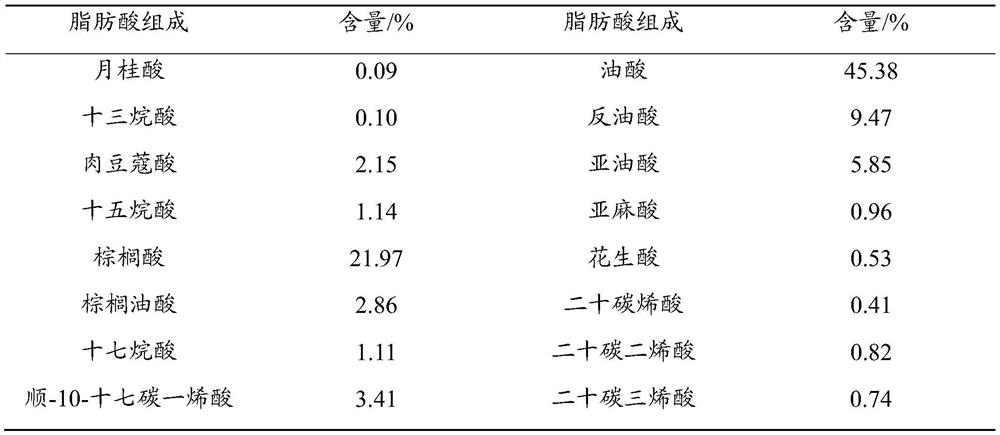

Embodiment 1

[0025] Wash the obtained sheep tail part, remove the external connective tissue, cut into pieces of about 1 cm, grind it with a meat grinder, weigh 7 g of the ground sheep tail meat and place it in a 50 mL centrifuge tube for later use. Prepare a dipotassium hydrogen phosphate / potassium dihydrogen phosphate buffer solution with a pH of 8, and mix mutton tail meat with 28 mL of phosphate buffer solution at a material-to-liquid ratio of 1:4. Add a trypsin solution with a final concentration of 3.2% (w / v), mix well, and incubate the enzymolysis in a constant temperature water bath shaker at 50°C for 2h. After the reaction, heat to 90°C and keep for 10min to inactivate the enzyme. The centrifuge tube was centrifuged at a speed of 4000 rpm for 10 minutes to separate the extracted sheeptail oil. The sheeptail oil was clear and transparent, and the extracted sheeptail oil was weighed to be 5.65g, and the calculated extraction rate was 80.71%. The sheeptail oil obtained was detected b...

Embodiment 2

[0029] Wash the obtained sheep tail part, remove the external connective tissue, cut into pieces of about 1 cm, grind it with a meat grinder, weigh 7 g of the ground sheep tail meat and place it in a 50 mL centrifuge tube for later use. Prepare a dipotassium hydrogen phosphate / potassium dihydrogen phosphate buffer solution with a pH of 8, and mix mutton tail meat with 28 mL of phosphate buffer solution at a material-to-liquid ratio of 1:4. Add a trypsin solution with a final concentration of 0.8% (w / v), mix well, and incubate the enzymolysis in a constant temperature water bath shaker at 50°C for 2h. After the reaction, heat to 90°C and keep for 10min to inactivate the enzyme. The centrifuge tube was centrifuged at a speed of 4000 rpm for 10 minutes to separate the extracted sheeptail oil. The sheeptail oil was clear and transparent, and the extracted sheeptail oil was weighed to be 5.16g, and the extraction rate was calculated to be 73.71%. The obtained sheep tail oil is dete...

Embodiment 3

[0031] Wash the obtained sheep tail part, remove the external connective tissue, cut into pieces of about 1 cm, grind it with a meat grinder, weigh 7 g of the ground sheep tail meat and place it in a 50 mL centrifuge tube for later use. Prepare a dipotassium hydrogen phosphate / potassium dihydrogen phosphate buffer solution with a pH of 8, and mix mutton tail meat with 28 mL of phosphate buffer solution at a material-to-liquid ratio of 1:4. Add a trypsin solution with a final concentration of 0.32% (w / v), mix well, and incubate the enzymolysis in a constant temperature water bath shaker at 50°C for 4 hours. After the reaction, heat to 90°C and keep for 10 minutes to inactivate the enzyme. The centrifuge tube was centrifuged at a speed of 4000rpm for 10min to separate the extracted sheeptail oil. The sheeptail oil was clear and transparent, and the extracted sheeptail oil was weighed to be 5.01g, and the extraction rate was calculated to be 71.57%. The sheeptail oil obtained was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com