Mounting structure and mounting method for anti-seismic support hanger in mechanical and electrical installation

A technology of installation structure and support and hanger, which is applied in the direction of pipeline support, mechanical equipment, pipe/pipe joint/pipe fitting, etc., to achieve the effect of improving efficiency and reducing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

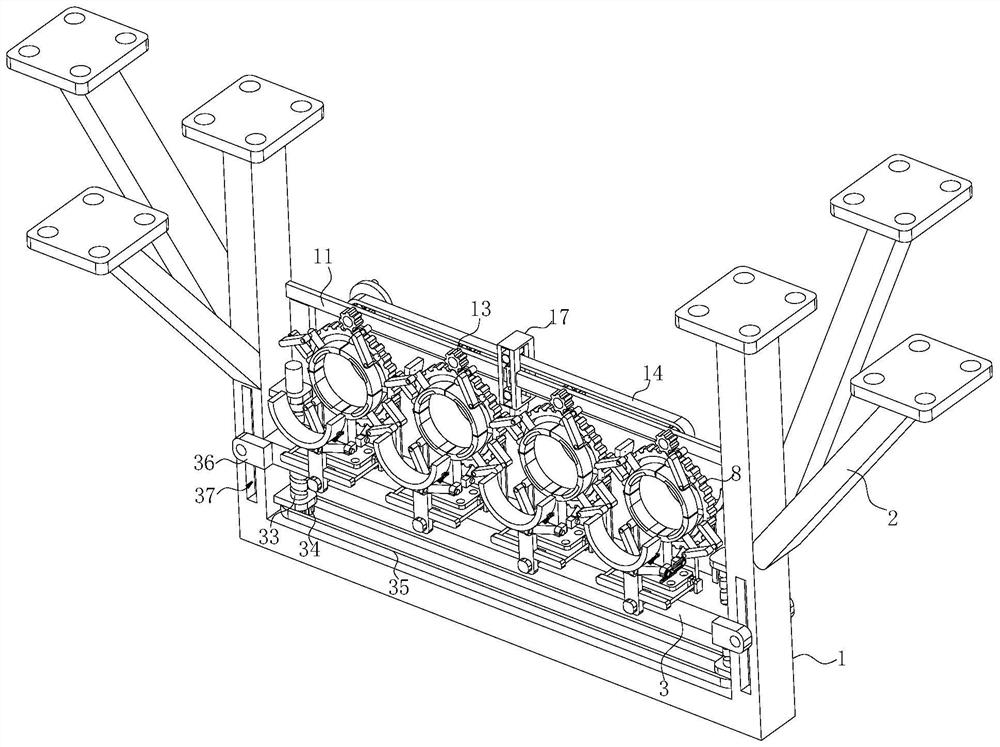

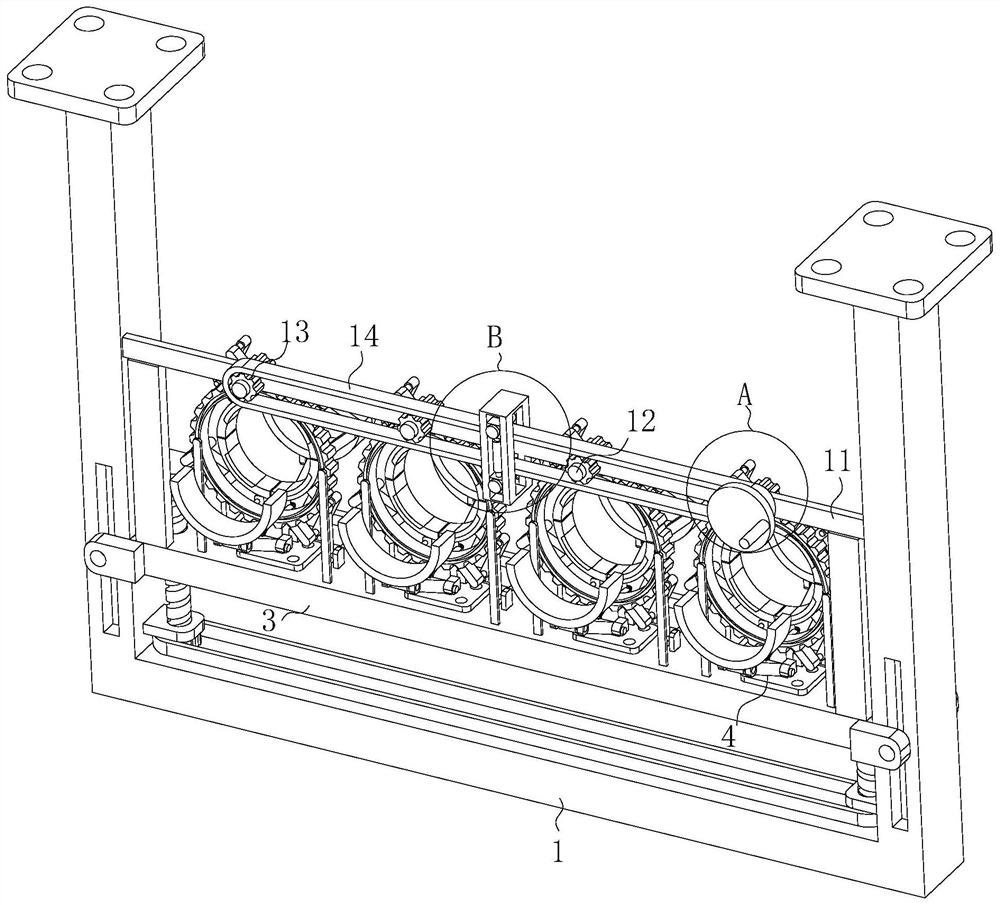

[0035] see Figure 1-11, the present invention provides a technical solution: an installation structure of an anti-seismic support and hanger in electromechanical installation, including a U-shaped fixed frame 1, and two sets of oblique support channel steel 2 are rotatably connected to the outer wall of the U-shaped fixed frame 1, and U-shaped The inner wall of the fixed frame 1 is connected with a first mounting plate 3, and the top of the first mounting plate 3 is fixedly connected with a horizontal linear array of fixed brackets 4, and each fixed bracket 4 has four first sliding rods slidingly connected to it. 5. The inner end of each first slide bar 5 is fixedly connected with a clamping plate 6, the clamping plate 6 is embedded on the inner wall of the fixed bracket 4, and the top of the first mounting plate 3 is fixedly connected with several sets of first supporting plates 7 Each group of two first support plates 7 front side walls are jointly slidably connected with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com