Split type steam generator

A steam generator, split-type technology, applied in the direction of steam generation, steam generation method, steam boiler, etc., can solve problems such as short circuit of electrical components, accelerated aging of electrical components, fire, etc., to avoid potential safety hazards, ensure service life, avoid washout effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

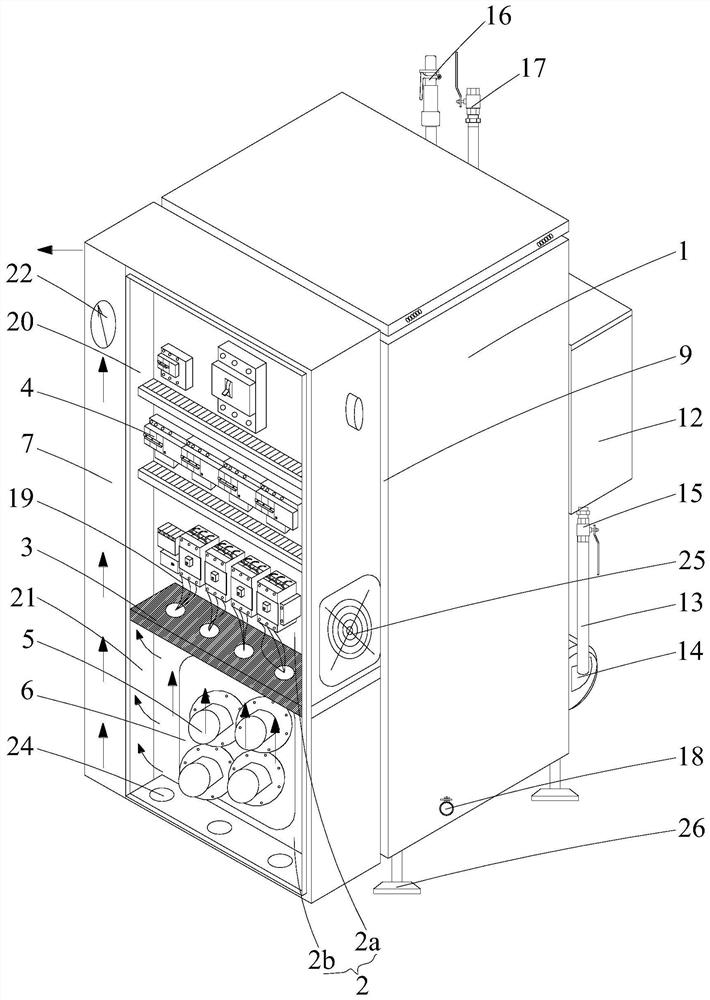

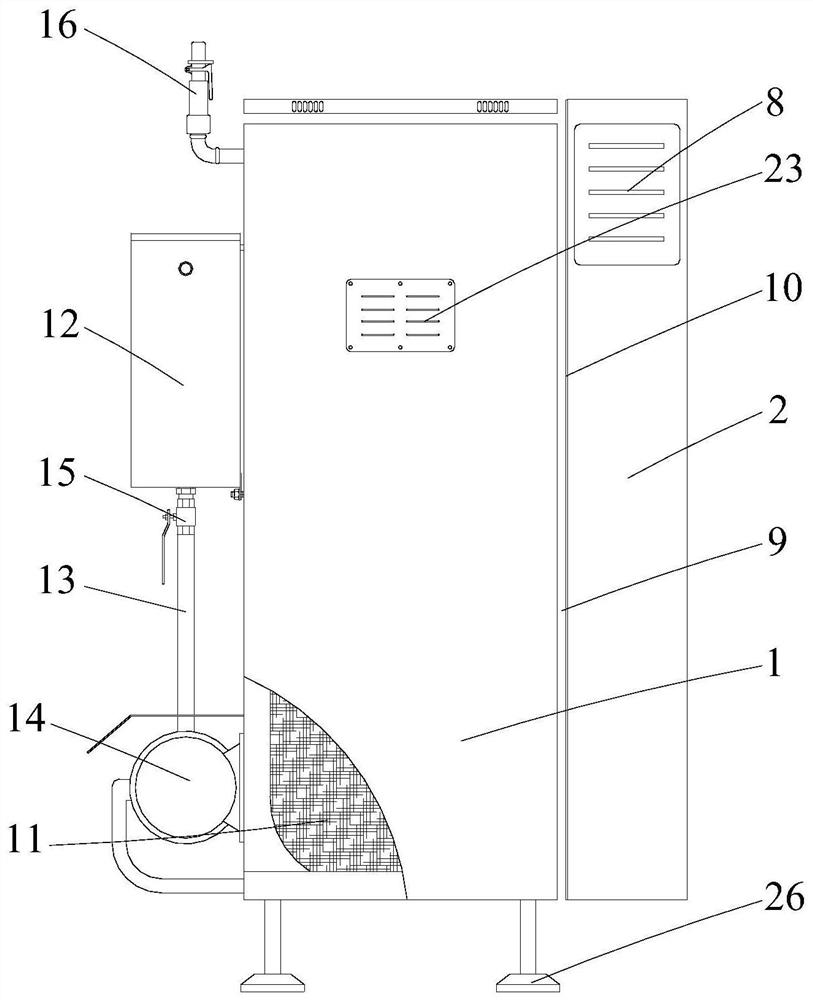

[0020] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0021] The present invention relates to the improvement of the steam generator, and proposes a split type steam generator, by installing the furnace and electrical components 4 in the first cabinet 1 and the second cabinet 2 respectively, avoiding leakage of the furnace When water or steam scours the electrical components 4, the separation of water and electricity is realized, and potential safety hazards are avoided; at the same time, the second cabinet body 2 is divided into a first cavity 2a and a second cavity 2b by using the first heat insulation layer 3, so that The electrical element 4 can be separated from the heating module 5 , preventing the hot air around the heating module 5 from affecting the electrical element 4 and ensuring the service life of the electrical element 4 .

[0022] see Figure 1-2 As shown, a split type steam gene...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap