Fiber laser on-line monitoring system

A monitoring system and fiber laser technology, applied in optical instrument testing, measuring devices, testing optical performance and other directions, can solve the problems of poor protection effect of monitoring equipment, inconvenient coupling of optical fibers for collection and storage, and lack of flexible portability of monitoring equipment, etc. The effect of increasing the anti-slip effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

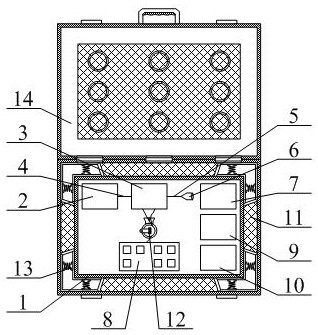

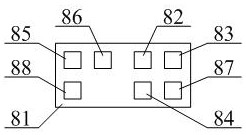

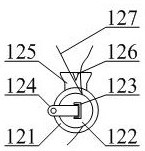

[0038] as attached figure 1 And attached Figure 4As shown, the present invention provides a fiber laser online monitoring system, including an installation frame 1, a laser generating component 2, a fiber sampler 3, a left transmission fiber 4, a right transmission fiber 5, a laser output head 6, and an end detection unit 7. The middle detection unit 8, the signal processing circuit 9 and the data processing and acquisition unit 10, the installation frame 1 is placed in the middle position inside the storage frame 141, and it is convenient to remove the installation frame 1 from the storage frame 141 according to the requirement during use , and then it is convenient to maintain the parts on the installation frame 1; the laser generating part 2, the fiber sampler 3 and the end detection unit 7 are installed on the upper side of the installation frame 1 in sequence from left to right; the left The side transmission fiber 4 is plugged in on the left side of the fiber sampler 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com