Coextruded polymeric netting and method of making the same

A co-extrusion and polymer technology, applied in the field of co-extrusion polymer netting and its manufacture, can solve the problems of high cost of chemical groups, inconvenience, difficulty in using triggers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

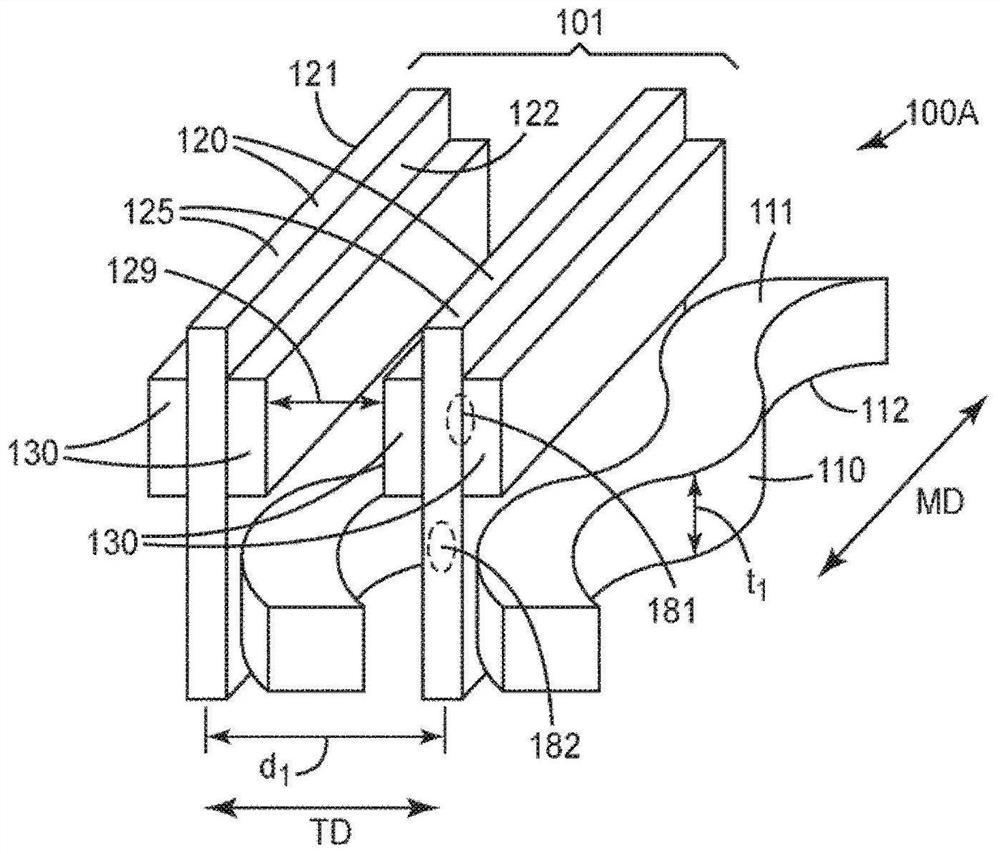

[0145] prepared as Figure 14 A coextrusion die generally shown in , which utilizes a coextrusion die such as Figure 11 with Figure 12 A multi-shim repeating pattern of extrusion orifices shown roughly in . The thickness of the shims in the repeating sequence was 4 mils (0.102 mm) for shims 600, 700, 800, 900, and 1000, and 2 mils (0.51 mm) for shim 500. The shim patterns are shown in Figures 5, 6, 7, 8, 9 and 10. These spacers are formed from stainless steel with perforations cut by wire EDM. The shims were stacked in a repeating sequence of 500, 600, 600, 700, 700, 800, 500, 900, 900, 1000, 1000, 900, and 900. The extrusion orifices are aligned in a collinear alternating arrangement. The total width of the spacer device was about 7.5 cm (3 inches).

[0146] The inlet fittings on the two end blocks each connected to three conventional single screw extruders. The extruder feeding both cavities was loaded with polyethylene copolymer (obtained under the trade designatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com