Resin composition for molding materials, molded body, and method for producing resin composition for molding materials

A resin composition and a manufacturing method technology are applied in the manufacturing field of resin compositions for molding materials, moldings and resin compositions for molding materials, which can solve the problems of adhesion to peripheral parts and the like, and achieve the effect of suppressing atomization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0126] Hereinafter, examples of the present invention will be described. In addition, this invention is not limited to these Examples. In addition, unless otherwise specified, "part" means a "mass part".

[0127] [Measurement method of physical properties]

[0128] The measurement methods of physical properties used in these examples are as follows.

[0129] Calculation of the fixation rate of acid anhydride on plant fiber

[0130] In the case of chemically modifying plant fibers with an acid anhydride, the fixation rate on plant fibers is calculated from the following formula.

[0131] Fixation rate (%)=(dry weight of modified plant fiber-dry weight of plant fiber) / (dry weight of plant fiber)×100

[0132] In addition, the dry weight of the modified plant fiber was measured by the following method. 100 times the quality of tetrahydrofuran was added to the total amount of modified plant fibers obtained by the method of Manufacturing Example 1 to prepare a dispersion liqui...

manufacture example 1

[0142] The solid content of 500 mass parts of packing into the clean container is the conifer bleached kraft pulp (NBKP) of 20 mass % and the N-methylpyrrolidone (NMP) of 150 mass parts, removes water by decompression, then drops into 19.9 mass parts Parts of hexadecenyl succinic anhydride, and reacted at 80°C for 4 hours. After the reaction, NMP was distilled off under reduced pressure to obtain modified cellulose fibers (A-1). The fixing rate of hexadecenyl succinic anhydride was 8.6%.

[0143] [Manufacture of resin composition 1]

Embodiment 1

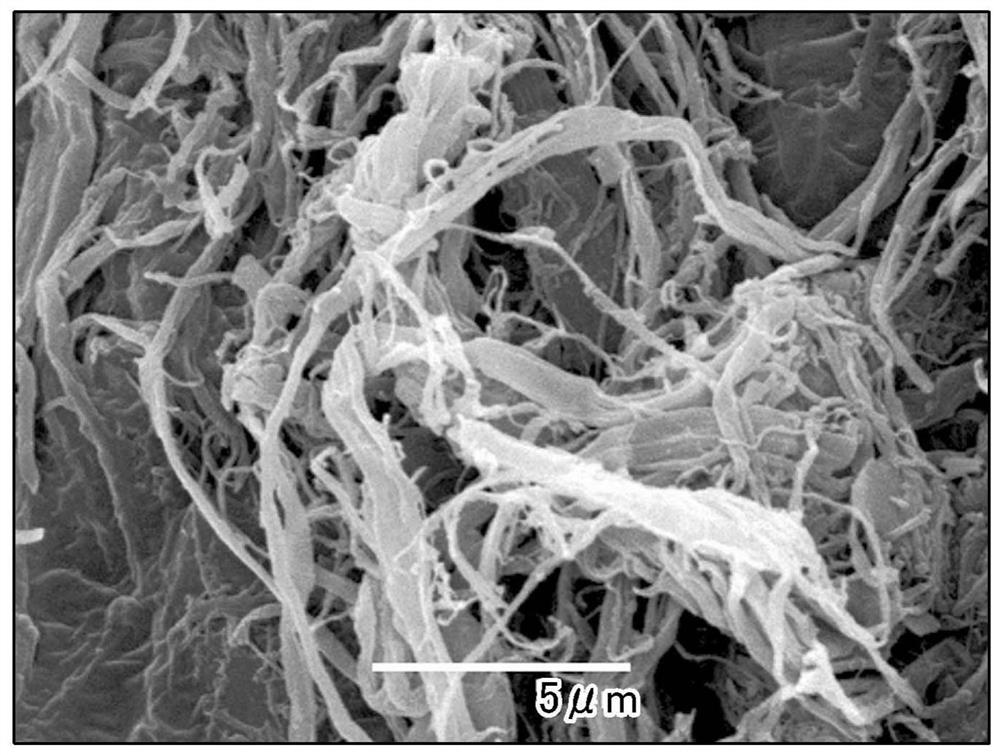

[0145] 25 parts of modified cellulose fibers (A-1), 75 parts of commercially available polypropylene resin (PP resin) (B, NOVATEC MA04A manufactured by Nippon Polypropylene Co., Ltd.), and 4 parts of Amino group compound (C-1, CARBODILITE HMV-15CA manufactured by Nisshinbo Chemical Co., Ltd.) was used as a compound having reactivity with carboxyl group using LABO PLASTOMILL (Toyo Seiki Manufacturing Co., Ltd.), which is one of the kneaders. production) and melt-kneaded at 170°C to obtain a resin composition (D-1). Modified cellulose fibers (A-1) are opened to nanofibers and dispersed in polypropylene resin (B) ( figure 1 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com