Efficient welding equipment based on high-power laser flight welding

A welding equipment and high-power technology, which is applied in the direction of laser welding equipment, welding equipment, welding equipment, etc., can solve the problems of affecting clamping stability, affecting processing or use, and cumbersome operation, so as to improve welding effect and prevent pinching Effects of workpieces and simplification of operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

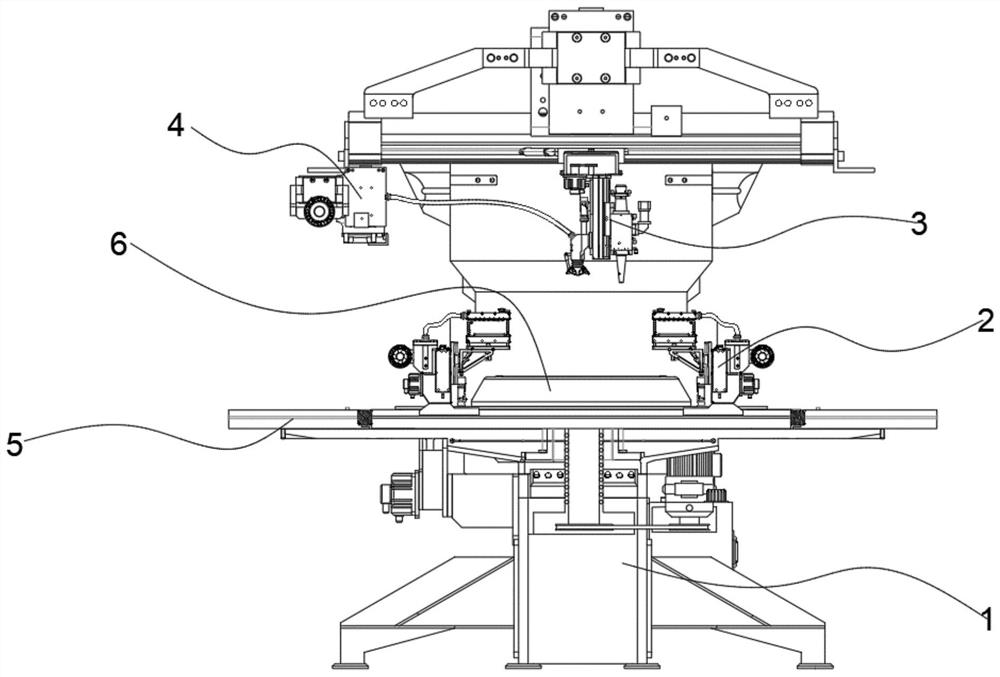

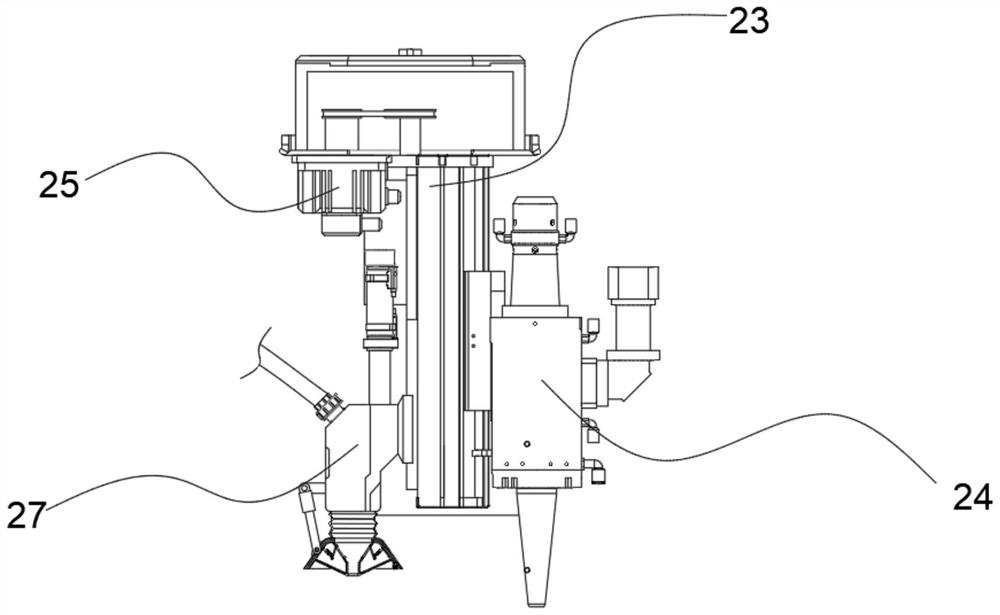

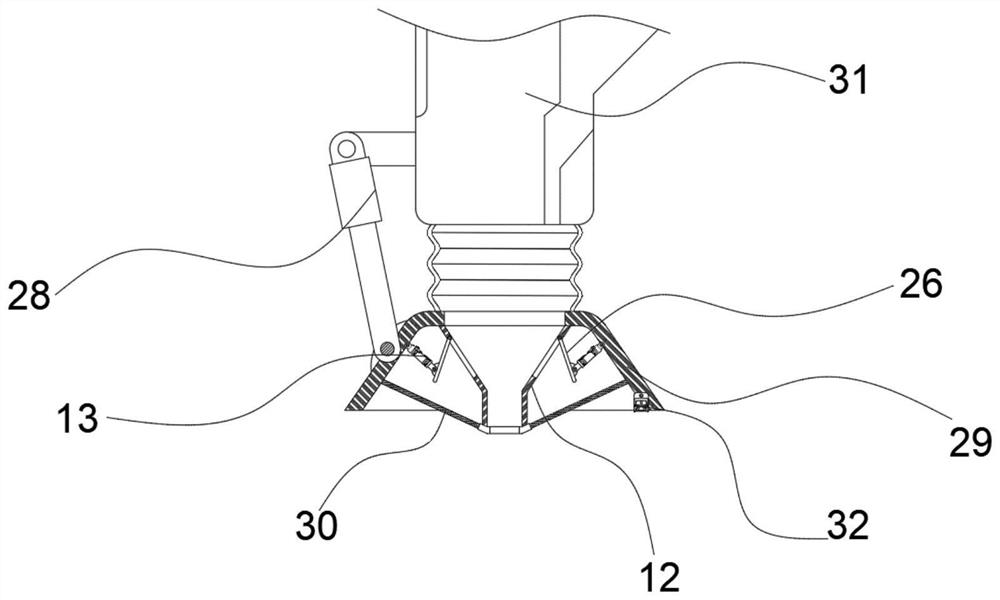

[0033] see figure 1 , in an embodiment of the present invention, a high-efficiency welding device based on high-power laser flying welding, which includes a frame 1, a positioning assembly 2, and a welding assembly 3, wherein the welding assembly 3 is slidably installed in the middle of the top of the frame 1 , and, the welding assembly 3 can slide left and right or forward and backward relative to the frame 1, so as to realize the linear welding of the workpiece; a worktable 5 is arranged directly below the welding assembly 3, and the middle part of the worktable 5 rotates A rotating disk 6 is provided, and the rotating disk 6 is driven to rotate by a rotating motor fixed below the frame 1; the positioning assembly 2 is symmetrically slid left and right on the rotating disk 6, and is driven to slide by the cylinder 15 fixed thereon ; The left side of the upper end of the frame 1 is also provided with a dust suction and purification device 4, and the dust suction and purificat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com