Camouflage space cloth material and preparation method thereof

A space and camouflage technology, applied in chemical instruments and methods, lamination, coating, etc., can solve the problems of space cloth material stiffness, insufficient softness, and easy creases, so as to avoid ink sticking to rollers and high peel strength , not easy to white mark effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

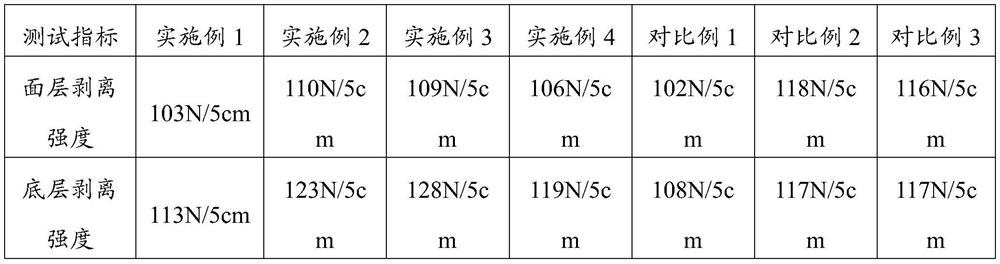

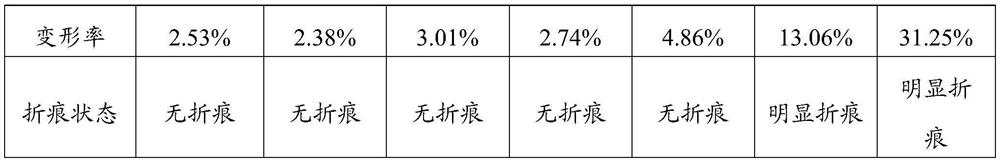

Examples

preparation example Construction

[0013] The present invention provides a kind of preparation method of camouflage color space cloth material, comprises the following steps:

[0014] Step 1. Ironing the space cloth to remove surface moisture, pasting and drying the bottom side of the space cloth to obtain pasted space cloth; pasting the unprinted side of the camouflage printing film to obtain pasting camouflage printing film;

[0015] Step 2. Preheat the PVC base film and then attach it to the bottom layer of the pasted space cloth; attach the pasted camouflage printing film to the surface side of the pasted space cloth;

[0016] Step 3. Paste the PVC transparent film on one side of the printed pattern of the pasted camouflage printing film.

[0017] It can be seen from the above description that the beneficial effect of the present invention is that the preparation method of the camouflage space cloth material provided by the present invention is different from the existing method in that the printing film is...

Embodiment 1

[0029] The preparation method of camouflage space cloth material specifically comprises the following steps:

[0030] Step 1. Iron the space cloth with a hot roller at 110°C to remove surface moisture, paste and dry the bottom side of the space cloth to obtain pasted space cloth; paste the unprinted side of the camouflage printing film to obtain pasted camouflage Printing film; the amount of pasting on the camouflage printing film is 50gsm, and the amount of pasting on the space cloth is 65gsm;

[0031] The pasted paste is composed of EPVC paste and 4% PVC adhesion promoter and 0.2% fumed silica tackifier accounting for the total mass of E-PVC paste;

[0032] Described E-PVC paste is made up of the E-PVC resin of 100 weight parts, the DINP of 50 weight parts, the liquid barium zinc stabilizer of 2 weight parts;

[0033] Step 2. Preheat the PVC base film with a 150°C heat roller, then use the same 170°C heat roll to bond the PVC base film to the bottom layer of the pasted spac...

Embodiment 2

[0037] The preparation method of camouflage space cloth material specifically comprises the following steps:

[0038] Step 1. Iron the space cloth with a hot roller at 110°C to remove surface moisture, paste and dry the bottom side of the space cloth to obtain pasted space cloth; paste the unprinted side of the camouflage printing film to obtain pasted camouflage Printing film; the amount of pasting on the camouflage printing film is 60gsm, and the amount of pasting on the space cloth is 75gsm;

[0039] The pasted paste is composed of EPVC paste and 5% PVC adhesion promoter and 0.5% fumed silica tackifier accounting for the total mass of E-PVC paste;

[0040] Described E-PVC paste is made up of the E-PVC resin of 100 parts by weight, the DINP of 65 parts by weight, the liquid barium zinc stabilizer of 3 parts by weight;

[0041] Step 2. Preheat the PVC base film with a 170°C heat roller, then use the same 180°C heat roll to bond the PVC base film to the bottom layer of the pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com