Preparation method of flexible super-hydrophobic silica gel film

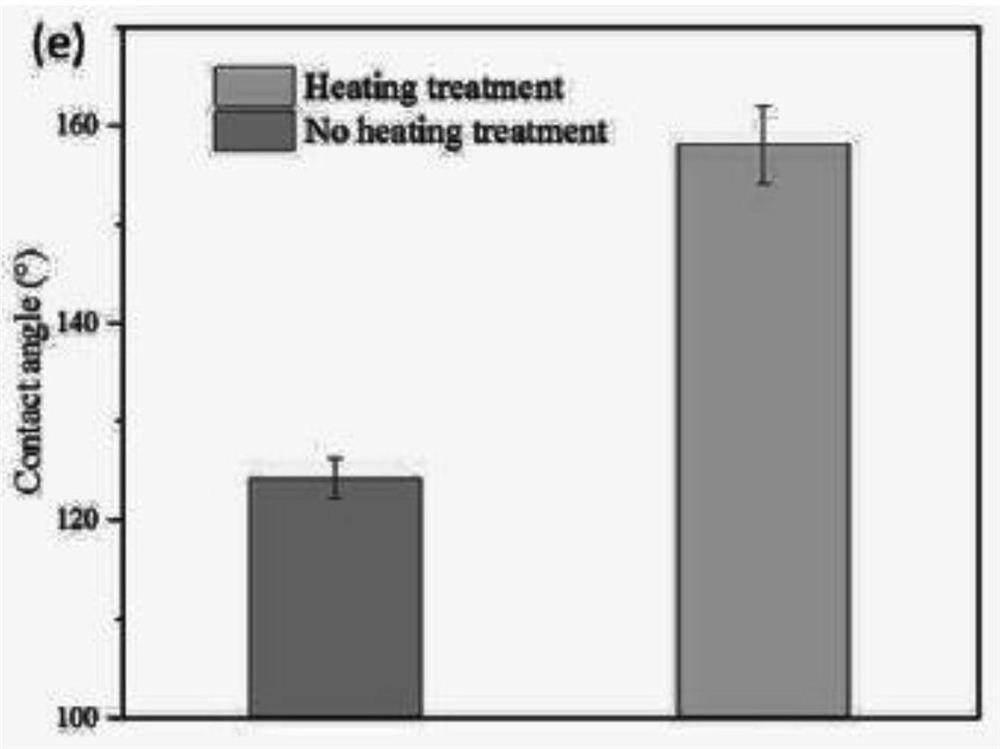

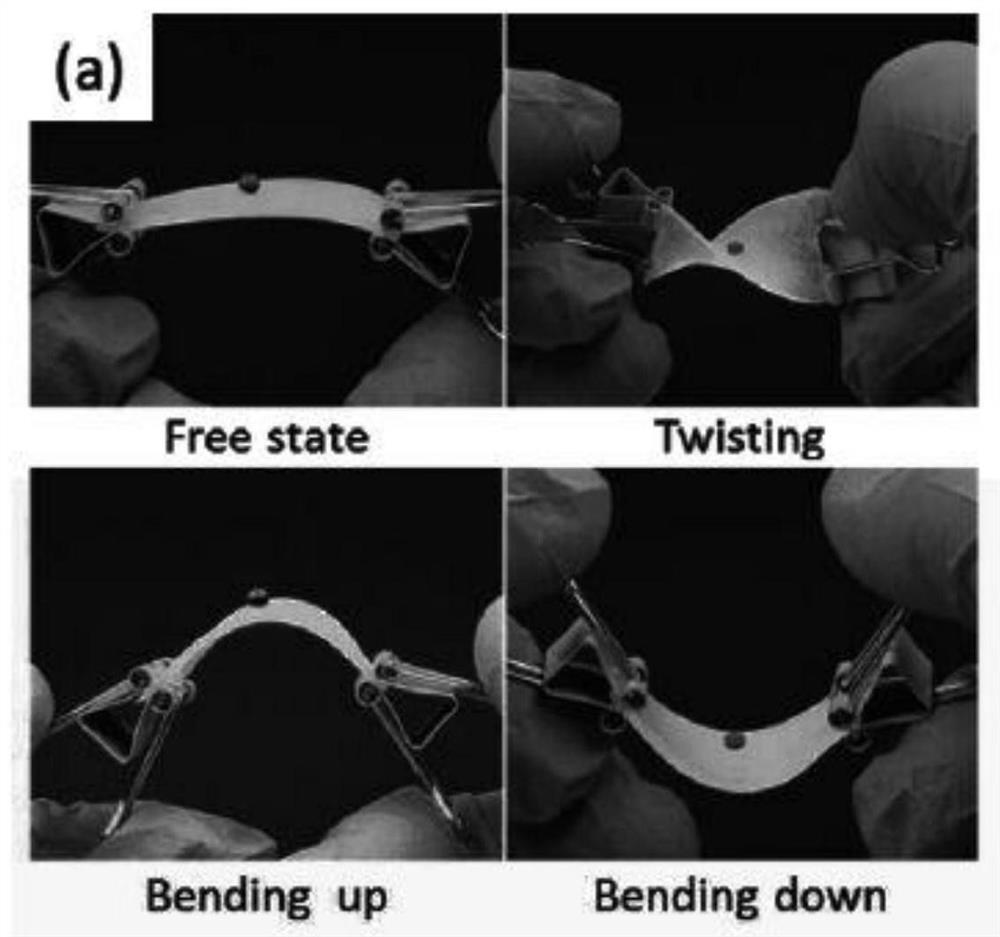

A silica gel film and super-hydrophobic technology, applied in the field of flexible super-hydrophobic silica gel film preparation, can solve the problems of stoppage and the microstructure being easily damaged by the outside world, and achieve the effects of improving the rubbing accuracy, improving the corrosion time, and stabilizing the surface wettability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

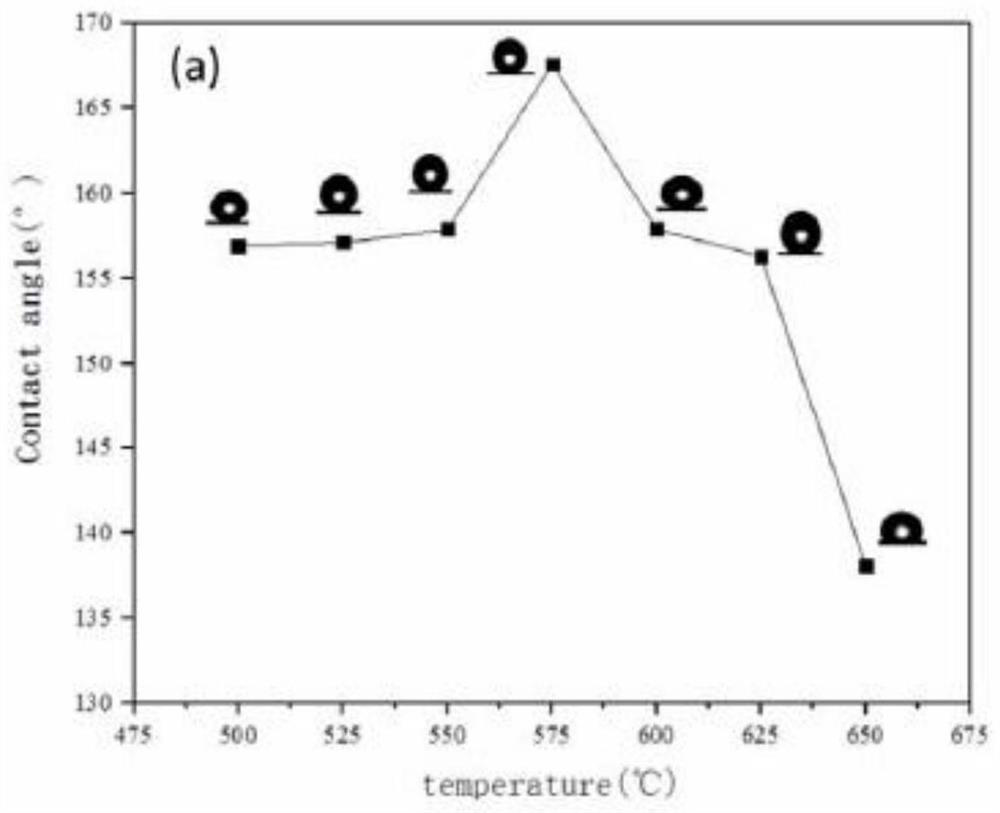

Embodiment 1

[0022] S1. Anneal the pure aluminum sheet in a resistance furnace at 575°C for 3 hours, take it out, air-cool to room temperature and ultrasonically clean it with deionized water for 5 minutes. Then put the evenly mixed Baker's solution into a heating agitator, place the aluminum sheet in the Baker's solution to react for a few minutes, take it out, wash it with deionized water, and dry it to obtain an aluminum template;

[0023] S2. Mix the PDMS prepolymer and the curing agent at a ratio of 10:1 and stir fully, put the beaker into a vacuum box and evacuate until all the bubbles disappear;

[0024] S3. Select sodium polystyrene sulfonate (PSSNa, Mw=7000Da) as a release agent, and dissolve a certain amount of PSSNa in a certain amount of deionized water to obtain a PSSNa solution. Then the PSSNa solution is evenly dispersed on the aluminum template after the treatment in the S1 step with a glue homogenizer at a speed of 300 rpm, and dried;

[0025] S4. Finally, pour the PDMS s...

Embodiment 2

[0027] S1. Anneal the pure aluminum sheet in a resistance furnace at 550°C for 3 hours, take it out, air-cool it to room temperature and ultrasonically clean it with deionized water for 5 minutes. Then put the evenly mixed Baker's solution into a heating agitator, place the aluminum sheet in the Baker's solution to react for a few minutes, take it out, wash it with deionized water, and dry it to obtain an aluminum template;

[0028] S2. Mix the PDMS prepolymer and the curing agent at a ratio of 10:1 and stir fully, put the beaker into a vacuum box and evacuate until all the bubbles disappear;

[0029] S3. Select sodium polystyrene sulfonate (PSSNa, Mw=7000Da) as a release agent, and dissolve a certain amount of PSSNa in a certain amount of deionized water to obtain a PSSNa solution. Then the PSSNa solution is evenly dispersed on the aluminum template after the treatment in the S1 step with a glue homogenizer at a speed of 300 rpm, and dried;

[0030] S4. Finally, pour the PDM...

Embodiment 3

[0032] S1. Anneal the pure aluminum sheet in a resistance furnace at 525°C for 3 hours, take it out, air-cool to room temperature and ultrasonically clean it with deionized water for 5 minutes. Then put the evenly mixed Baker's solution into a heating agitator, place the aluminum sheet in the Baker's solution to react for a few minutes, take it out, wash it with deionized water, and dry it to obtain an aluminum template;

[0033] S2. Mix the PDMS prepolymer and the curing agent at a ratio of 10:1 and stir fully, put the beaker into a vacuum box and evacuate until all the bubbles disappear;

[0034] S3. Select sodium polystyrene sulfonate (PSSNa, Mw=7000Da) as a release agent, and dissolve a certain amount of PSSNa in a certain amount of deionized water to obtain a PSSNa solution. Then the PSSNa solution is evenly dispersed on the aluminum template after the treatment in the S1 step with a glue homogenizer at a speed of 300 rpm, and dried;

[0035] S4. Finally, pour the PDMS s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com