Novel hydraulic motor reversing system

A hydraulic motor and reversing system technology, applied in the field of hydraulic motors, can solve the problems of reducing device use efficiency, wasting operator time and energy, and reducing device use effects, so as to avoid time and effort, increase processing efficiency, and improve use efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

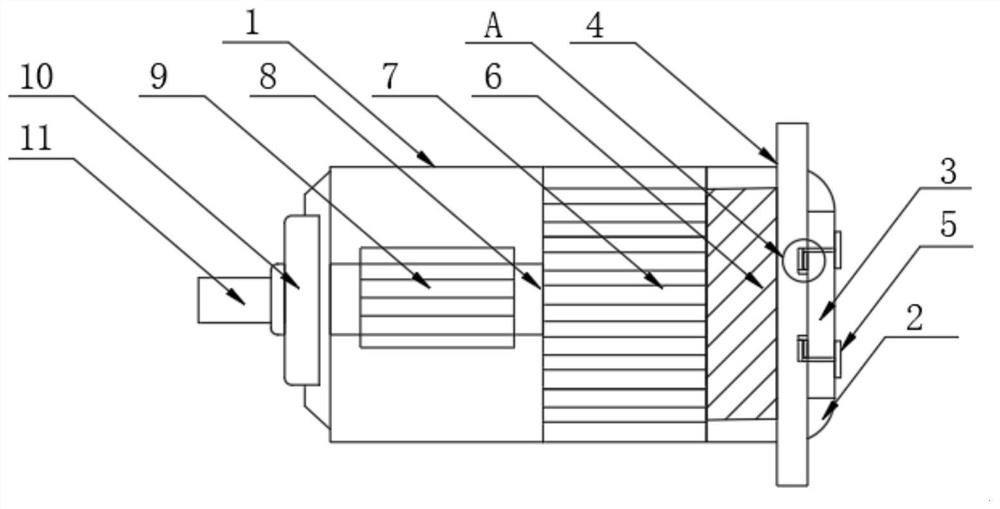

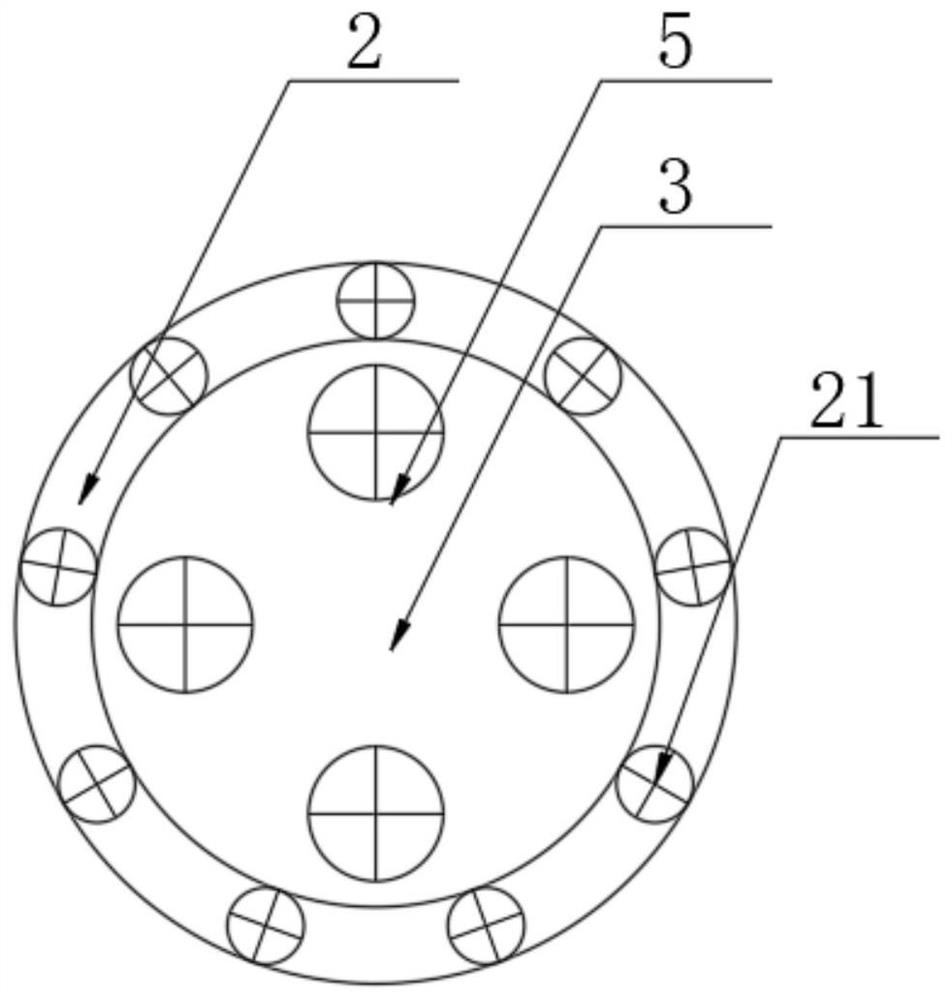

[0024] Specifically, the embodiment is as follows: the rear cover 2 is fixed on the tail of the housing 1 through the fixing screws 21, and the reversing dial 3 is detachably connected to the reversing device 4 through the locking device 5, which solves both the connection problem and the fixing problem.

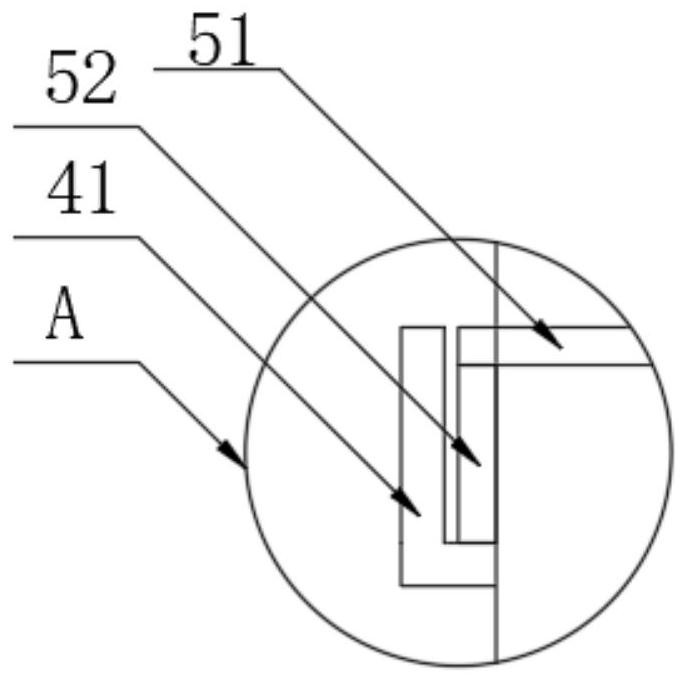

[0025] The specific reference manual is attached image 3 One side of the inner chamber of the reversing device 4 is fixedly equipped with a fixed buckle 41 , one side of the locking device 5 is fixedly connected with a locking rod 51 , and the end of the locking rod 51 is fixedly installed with a locking buckle 52 .

[0026] The specific embodiment is: the locking rod 51 drives the locking buckle 52 to be fixedly connected with the fixing buckle 41, which not only solves the connection problem but also solves the fixing problem.

[0027] The working principle of the present invention:

[0028] First assemble the parts of each part, and then when the device needs to perform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com