Fastener for nuclear power station

A technology for fasteners and nuclear power plants, which is applied in the direction of nuclear power generation, connecting components, reducing greenhouse gases, etc. It can solve the problems of difficult removal of fasteners and affect the use of fasteners, so as to avoid mutual bonding and facilitate transportation and installation , easy to seal the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

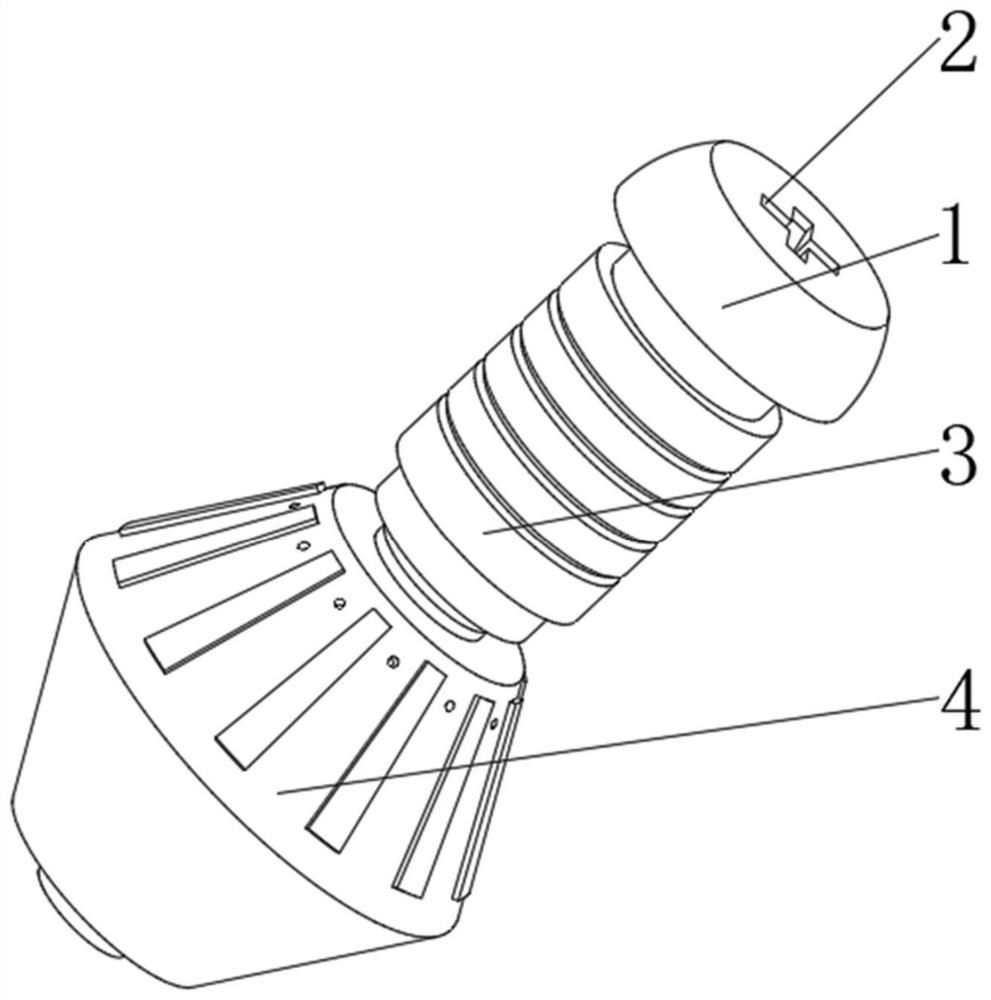

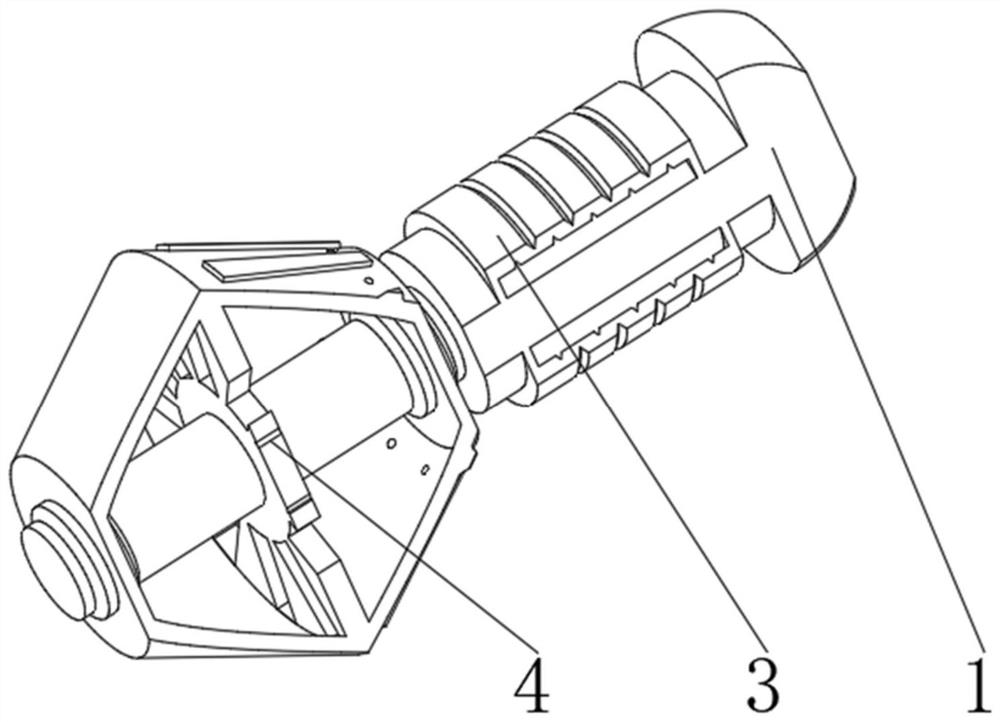

[0041] see Figure 1-3 , the present invention provides a technical solution: a fastener for nuclear power plants, specifically comprising:

[0042] Fixed cap 1, the fixed cap 1 has the main body of the round table, and the cross embedded groove 2 provided on the top of the main body of the round table, and the fixed bolt rod 3 fixed at the middle position of the bottom of the main body of the round table, and the one end of the fixed bolt rod 3 away from the main body of the round table. The pasting mechanism 4, through the design of the pasting mechanism 4 itself, when the fastener fails during use, the pasting mechanism 4 of the fastener can be directly destroyed by an external device, so as to realize the overall replacement of the fastener. To avoid contact between personnel and the inside of the components, and to avoid the radiation of the nuclear power plant from causing harm to personnel safety, the pasting mechanism 4 includes:

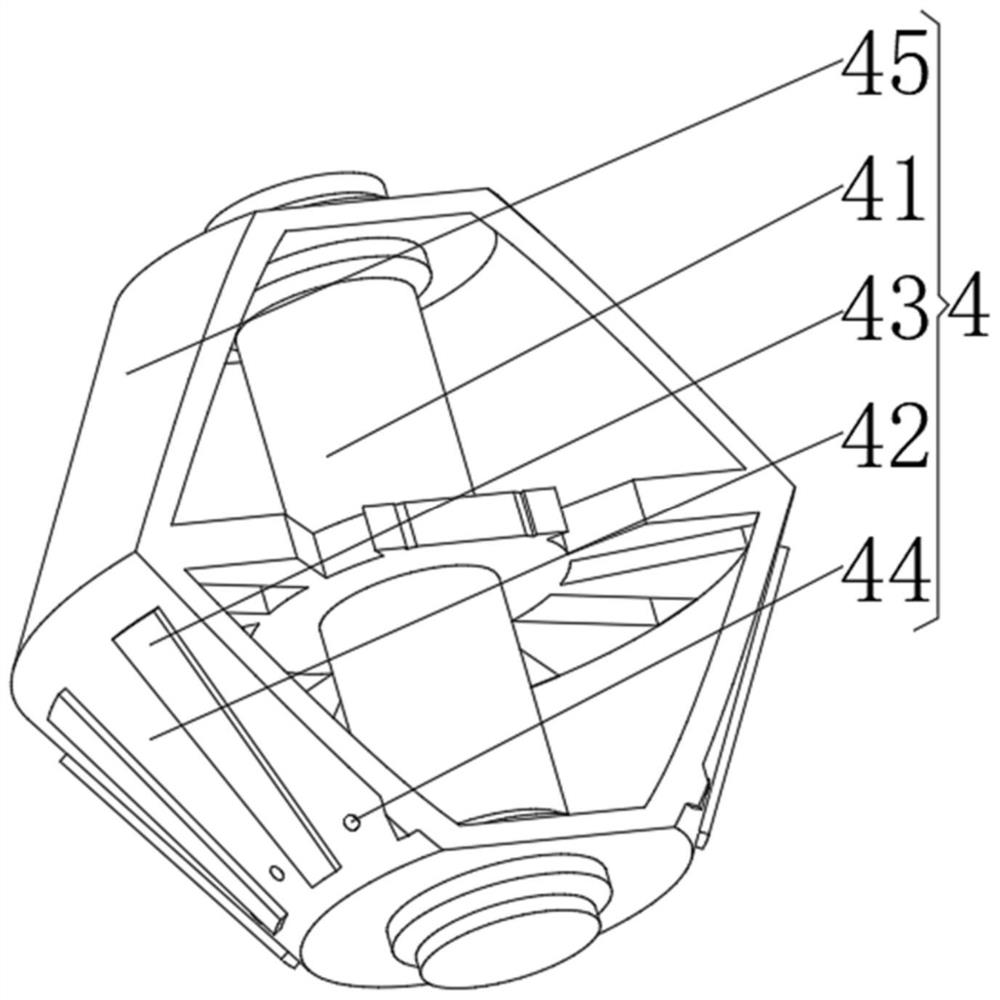

[0043] Transmission mechanism 41, the ...

Embodiment 2

[0047] see Figure 1-5 On the basis of Embodiment 1, the present invention provides a technical solution: the transmission mechanism 41 includes:

[0048] Transmission rod 411, the transmission rod 411 has an externally threaded cylinder rod, and an air bag 412 installed in the inner cavity of the externally threaded cylinder rod, and a ring plate 413 installed at the middle and lower position of the outer surface of the externally threaded cylinder rod, and installed outside the ring plate 413 The air pressure column 414 on the surface, and the ventilation pores 415 provided in the middle position of the external thread cylinder rod and the ring plate 413 . The design of the air pressure column 414 protects the sealing pressure plate 45 and the sealing bottom plate 42 to avoid damage caused by excessive stress concentration caused by excessive deformation. At the same time, the elasticity of the air pressure column 414 affects the shape of the components of the sealing pressu...

Embodiment 3

[0056] see Figure 1-6 , on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the fixed bolt 3 includes:

[0057] Bolt rod 31, this bolt rod 31 has thread cylinder, and the end plate 32 that is installed on the outer surface of thread cylinder, and is installed between end plate 32 and is positioned at the placement cylinder 33 of thread cylinder outside, and is opened in placement cylinder 33 There are annular grooves 34 on the inner surface and the outer surface, and capillary holes 35 provided on the outer surface of the placement cylinder 33 and between the annular grooves 34 . The secondary filling and sealing of the expansion sealing material is carried out by placing the cylinder 33, and at the same time, the self-protection ability of the fastener is promoted, the external environment is isolated, the penetration of external substances is avoided, and the service life of the component is extended and protected.

[0058] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com