Bragg type hollow-core anti-resonance optical fiber

An anti-resonance, optical fiber technology, applied in cladding optical fiber, microstructure optical fiber, light guide, etc., to achieve the effect of reducing optical fiber leakage, reducing optical fiber loss, and maintaining long-distance optical fiber drawing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following are specific embodiments of the present invention, and further describe the technical solution of the present invention in conjunction with the accompanying drawings, but the present invention is not limited to these embodiments.

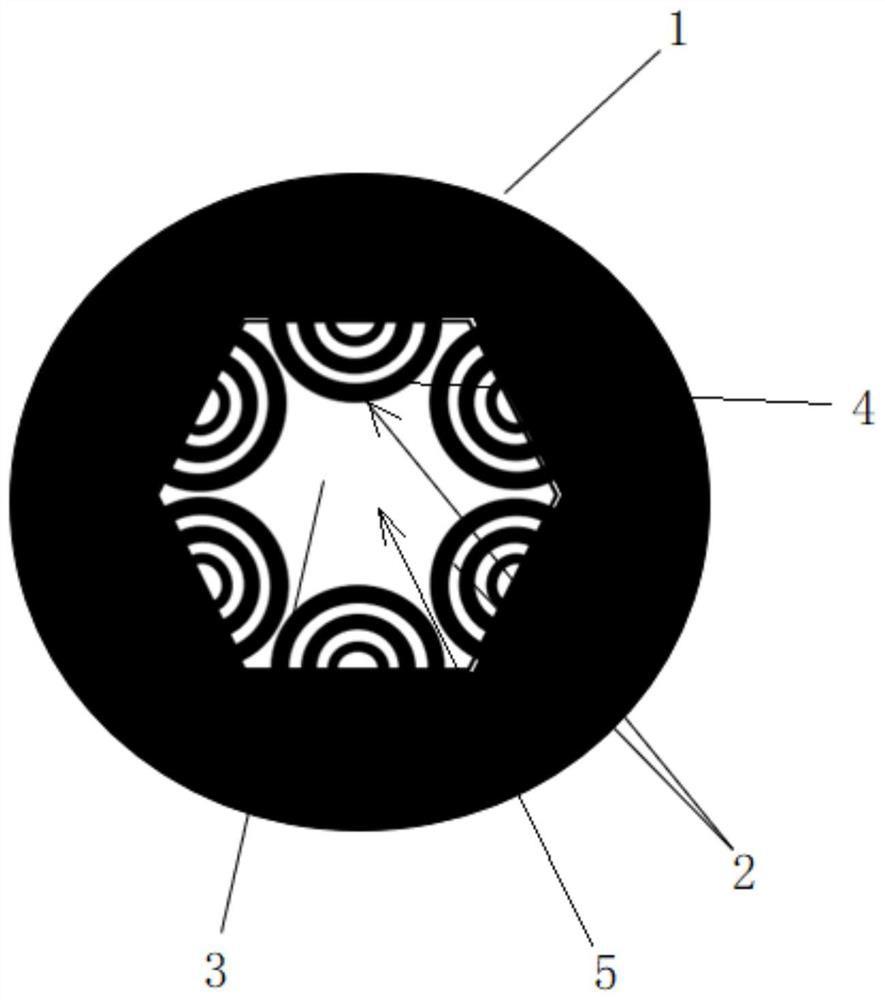

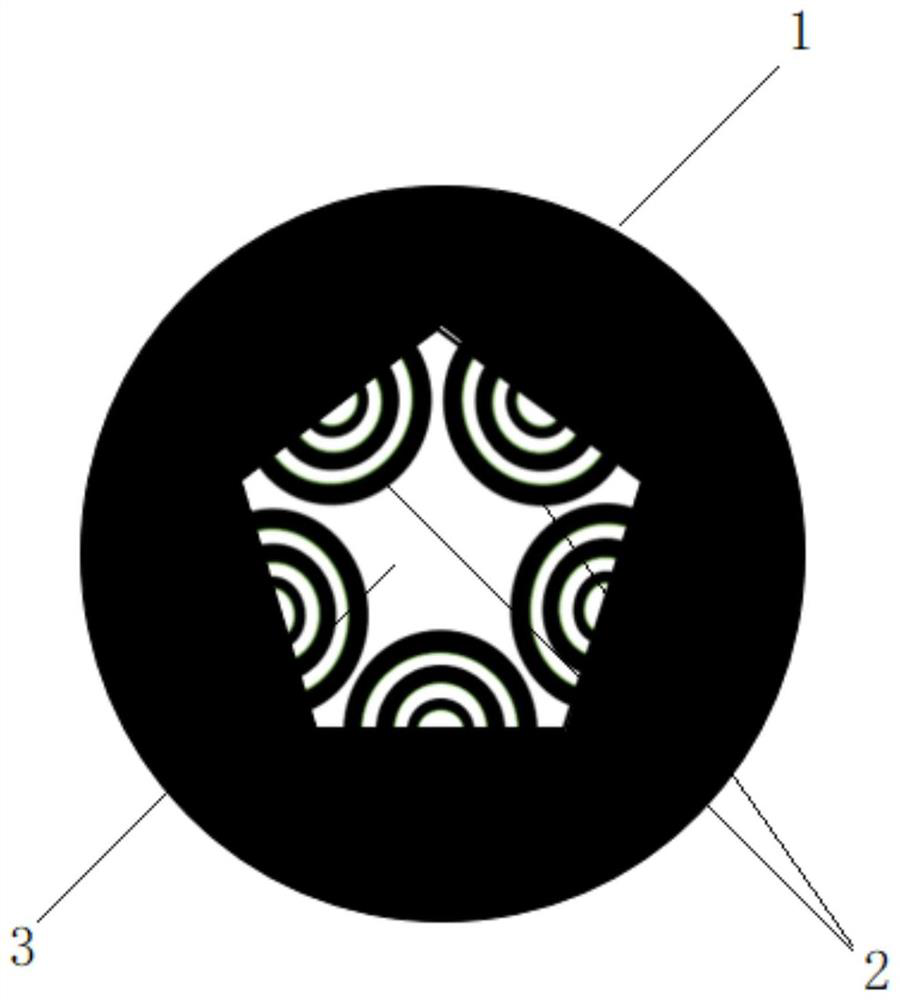

[0026] like figure 1 As shown, the Bragging hollow-core antiresonant fiber includes a fiber support part 1, a fiber inner cladding 2 and a fiber core 3, the fiber inner cladding 2 and the fiber core 3 are located inside the fiber support part 1, and the fiber inner cladding 2 includes several inner claddings Unit 4, there is air between adjacent inner cladding units 4, and there is no connection point.

[0027] In this hollow-core antiresonant optical fiber, the core 3 is air, and the inner cladding unit 4 of the optical fiber inner cladding 2 can be alternately combined with quartz and air, thereby forming a Bragg cladding, and the Bragg cladding has a strict structural arrangement. Periodicity, using the anti-resonance effect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com