Sealing equipment for vacuum display device

A technology for sealing equipment and display devices, which is used in electrical components, the manufacture of discharge tubes/lamps, and the closing of electric tubes/lamps. , to achieve the effect of improving the sealing effect, improving the leveling quality and improving the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

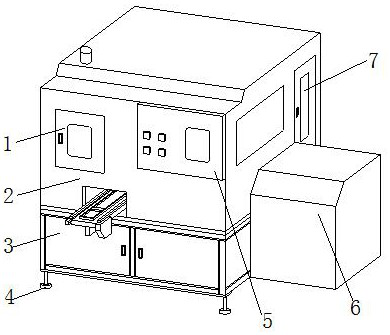

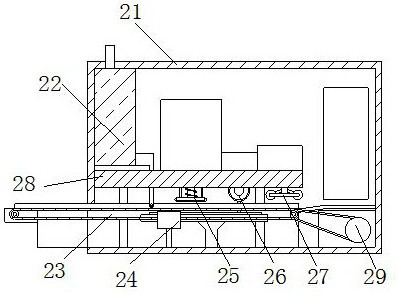

[0022] as attached figure 1 To attach Figure 5 Shown:

[0023] A sealing device for a vacuum display device according to the present invention, its structure includes an observation window 1, a sealing device main body 2, a tool box 3, feet 4, an operation panel 5, a motor box 6, and a material retrieving window 7, and the observation window 1 is set On the left side of the front end of the sealing device main body 2, the tool box 3 is embedded and installed on the bottom of the sealing device main body 2, the foot 4 is welded on the bottom of the tool box 3, and the operation panel 5 is arranged on the sealing device main body 2 On the right side of the front end, the motor box 6 is installed on the right bottom side of the sealing equipment main body 2, and the right end rear side of the sealing equipment main body 2 is provided with a material taking window 7, and the sealing equipment main body 2 includes a box body 21, a vacuum Air pump 22, conveyer belt 23, cooling de...

Embodiment 2

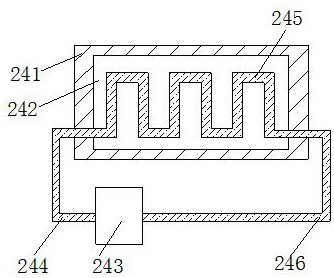

[0030] as attached Figure 6 to attach Figure 7 Shown:

[0031] Wherein, the cooling structure 26 includes an oil storage bin 261, a cooling roller 262, a connecting shaft 263, a tap inlet pipe 264, and a tap outlet pipe 265, and the oil storage bin 261 is embedded and installed inside the cooling roller 262. The left end of the connecting shaft 263 is embedded and connected with the right end of the cooling roller 262, and the upper and lower sides of the opening of the right end of the oil storage bin 261 are respectively cooled by the tap inlet pipe 264 and tap outlet pipe 265 and the bottom end of the oil storage bin 261. The device 24 is connected. The material of the cooling roller 262 is aluminum, and the heat conduction efficiency is good, so that the temperature of the heat-pressed seal of the display device is rapidly cooled. The branch inlet pipe 264 flows the cooling oil into the cooling roller 262, and cooperates with the tap outlet 265 flows out the cooling oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com