Jig for centering cutting of unilateral air gaps of small rectangular cores

A rectangular iron core, small technology, applied in the field of silicon steel coil iron core processing, to achieve the effect of simple structure, high production efficiency and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in further detail by the following examples.

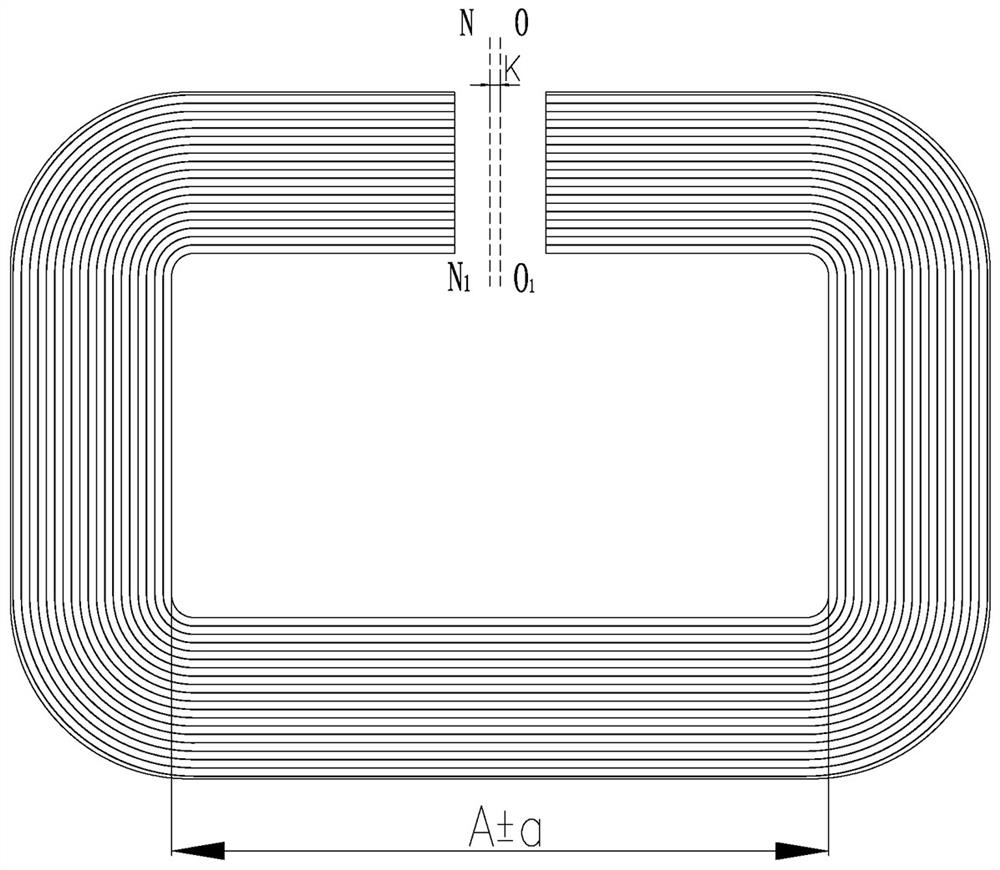

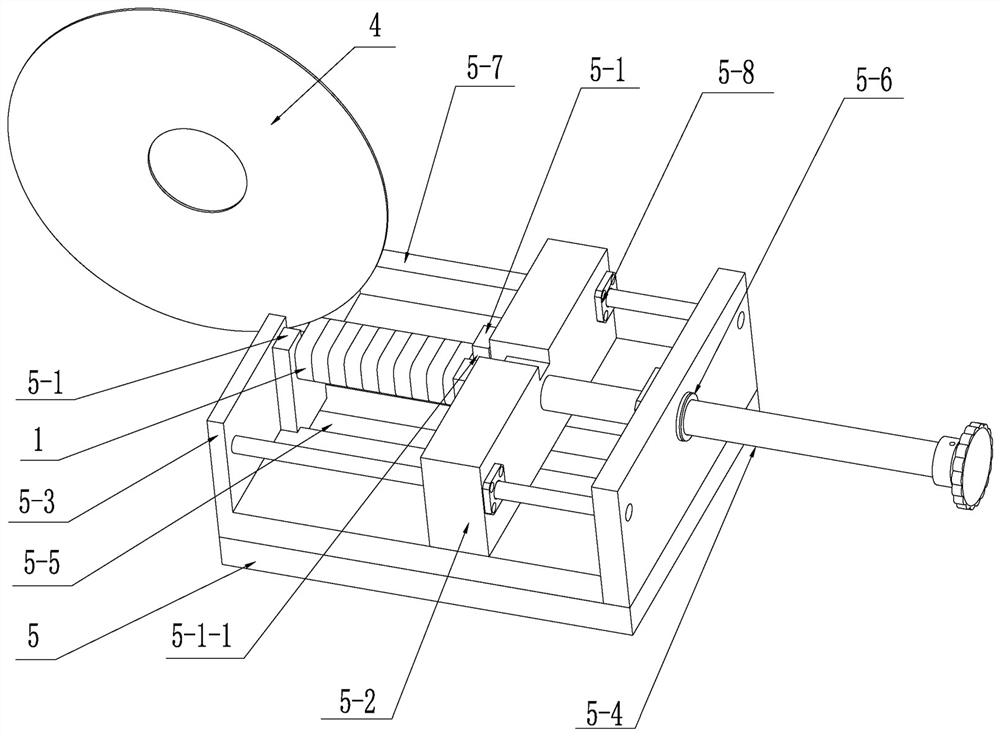

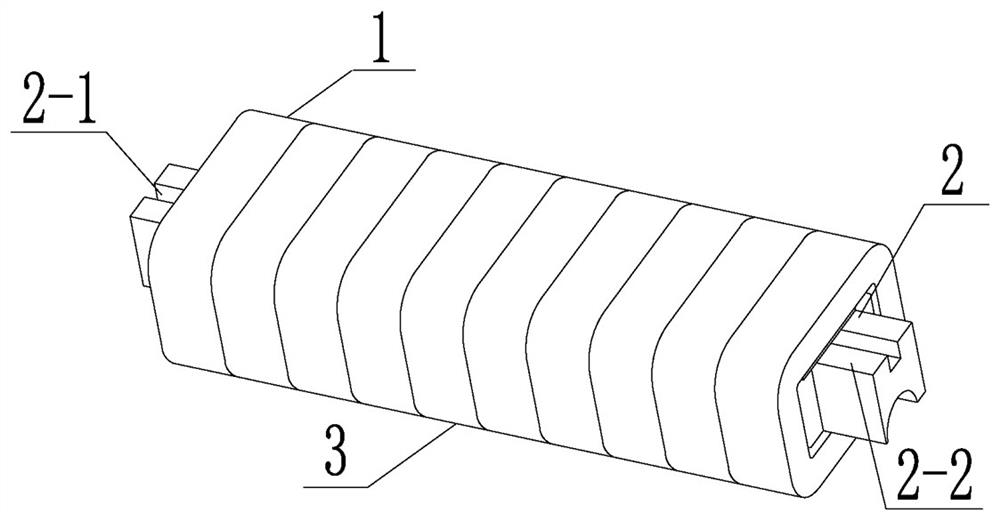

[0021] see Figure 1 to Figure 8 As shown, a small rectangular iron core unilaterally centered jig for cutting air gaps, including cutting clamps 5 and cutting dies 2, a row of n rectangular iron cores 1 inserted and supported on the cutting die 2, composed of The cutting die assembly 3 is also provided with an elastic positioning cutting die assembly 6, and the elastic positioning cutting die assembly 6 includes a base 6-1, side plates 6-2 arranged on the left and right sides of the base 6-1, the There are n equidistantly arranged elastic positioning members 6-3 arranged on the same level on the upper part of the two side plates 6-2. 1.0-1.5 mm, the bottom of the base 6-1 is matched and slidably connected with the second positioning groove 5-9 of the cutting clamp 5, and the cutting die assembly 3 is placed in the space formed by the two side plates 6-2. The front and rear positioning e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com