Self-drilling nail clamp

A drilling tail and nail clip technology, which is applied in the manufacture of tools, nail dispensers, packaging, etc., can solve problems affecting work efficiency, endangering workers at heights, and potential safety hazards, achieving firmness, overcoming the shaking of drill tail nails, and installation convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

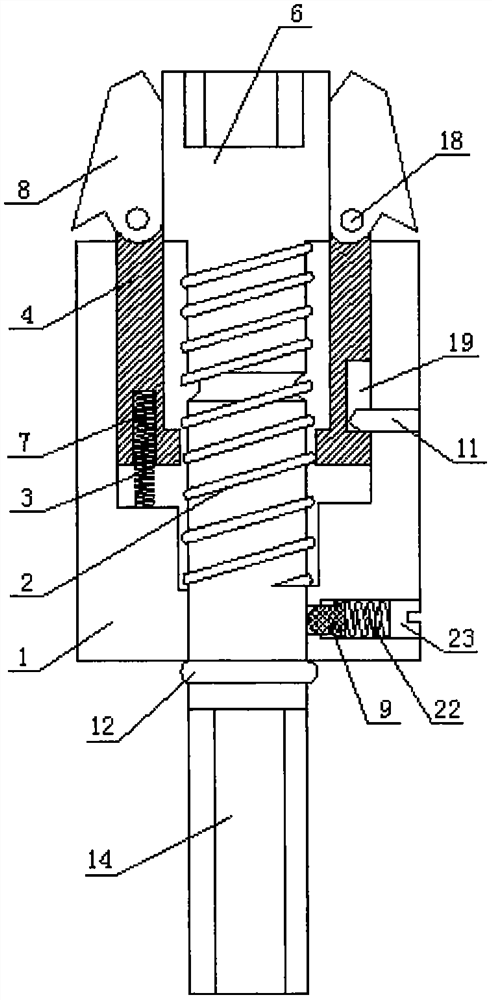

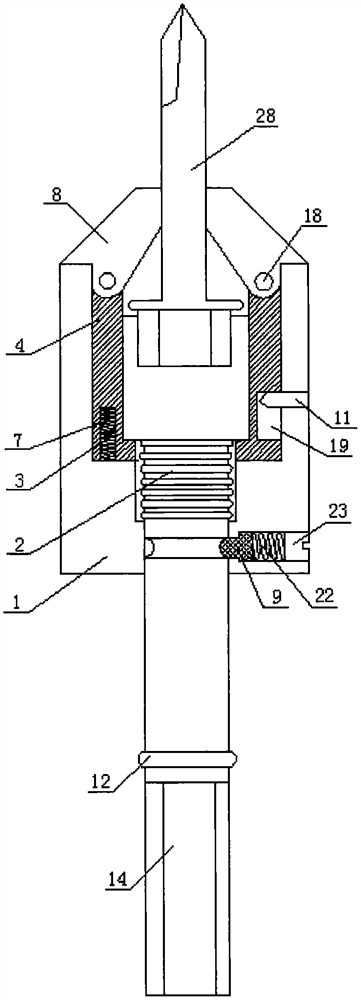

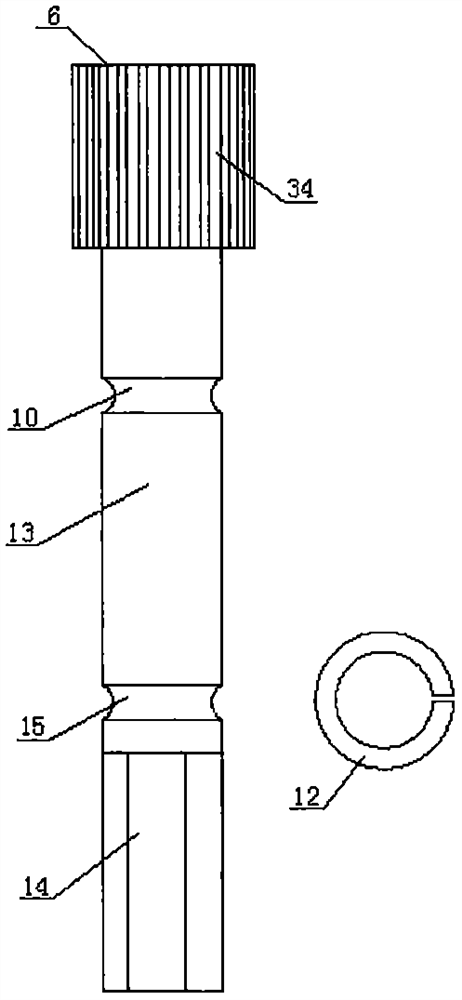

[0020] Such as figure 1 , figure 2 and image 3 As shown, the drill end nail clamp of this embodiment includes a nut base 6 , a magnet is arranged at the inner end of the nut base 6 , and a cylindrical nut rod 13 and a prismatic drill post 14 are formed at the rear end of the nail base 6 . The outer side of the nail cap seat 6 is provided with a nail cap seat tooth bar 34, the nail cap bar 13 is provided with a ring shaft groove 10, and between the ring shaft groove 10 and the drill clamp post 14 is provided with a terminal ring groove 15, and the terminal ring groove 15 is installed There is an end ring 12, the diameter of the nail cap seat 6 is greater than the nail cap rod 13, and the outer side of the nail cap seat 6 is sequentially sleeved with an inner tube body 4 and an outer tube body 1 from inside to outside. The weak spring 2 is sleeved on the nail cap rod 13, and the outer diameter of the end ring 12 is greater than the inner diameter of the inner wall of the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com