Efficient environment-friendly snow-melting biological liquid preparation

A technology of biological liquids and preparations, applied in other chemical processes, centrifuges, centrifuges with rotating drums, etc., can solve the problems of large adhesion, poor centrifugation effect, long centrifugation time, etc., to achieve fast and convenient The effect of cleaning and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

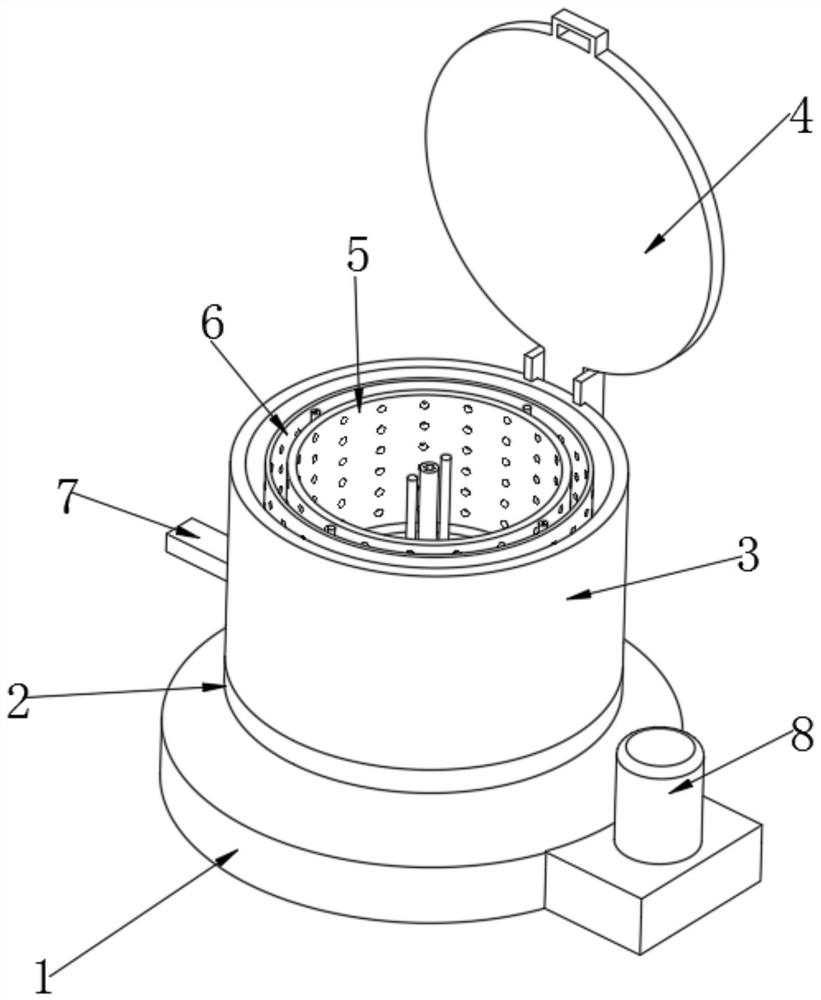

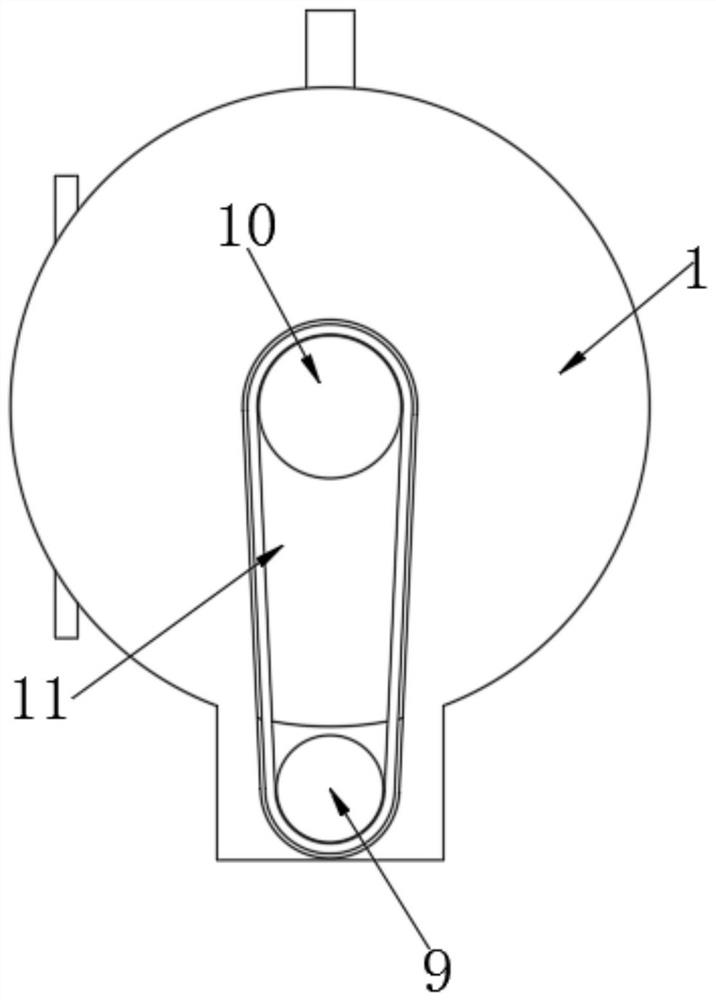

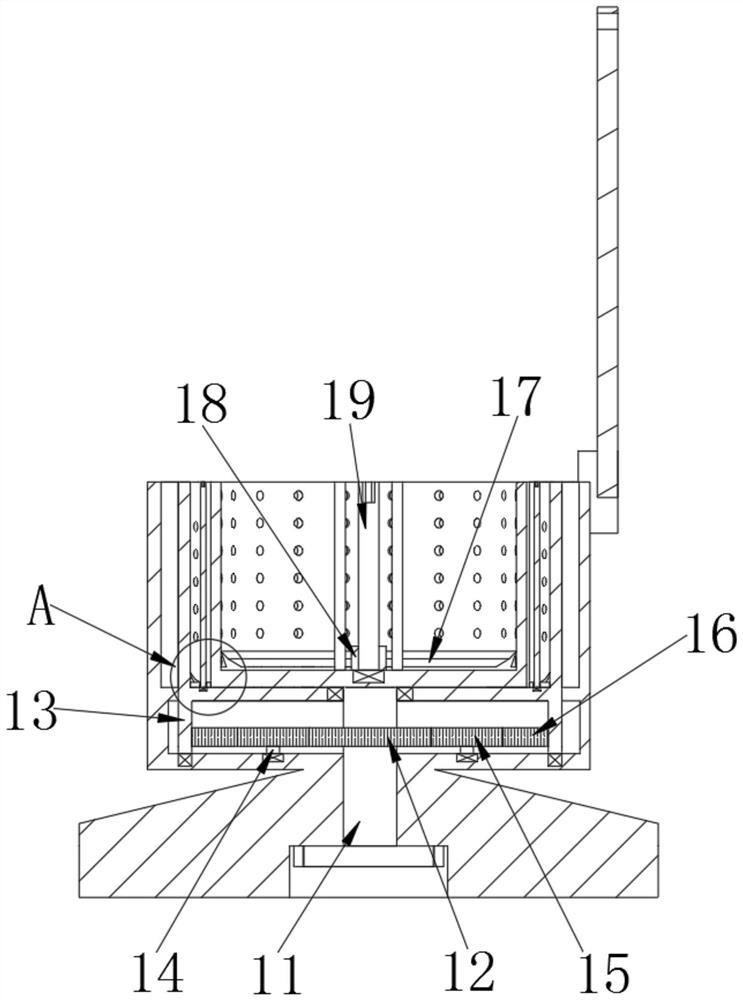

[0035] As an embodiment of the present invention, the centrifugal device includes a base 1, a transmission case 2, an outer cylinder 3, a cylinder cover 4, an inner filter cartridge 5 and an outer filter cartridge 6, the top of the base 1 is equipped with a transmission case 2, and the top of the transmission case 2 is The outer cylinder 3 is installed, and the bottom of the outer cylinder 3 is connected with a liquid outlet pipe 7, the inner filter cartridge 5 is installed in the rotation of the outer cylinder 3, and the outer filter cartridge 6 is installed in rotation between the outer cylinder 3 and the inner filter cartridge 5 , a cylinder cover 4 is installed on the outside of the outer cylinder 3;

[0036] A lifting plate 17 is slidably installed inside the inner filter cartridge 5, and a circular first scraper 20 contacting the inner wall of the inner filter cartridge 5 is arranged on the outside of the top of the lifting plate 17, and a lifting plate 20 is slidably ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com