High-strength woven bag production device and use method thereof

A production device, woven bag technology, applied in the directions of stretch spinning, transportation and packaging, textiles and papermaking, etc., can solve the problems of low manual packaging force, labor consumption, and low equipment fault tolerance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing:

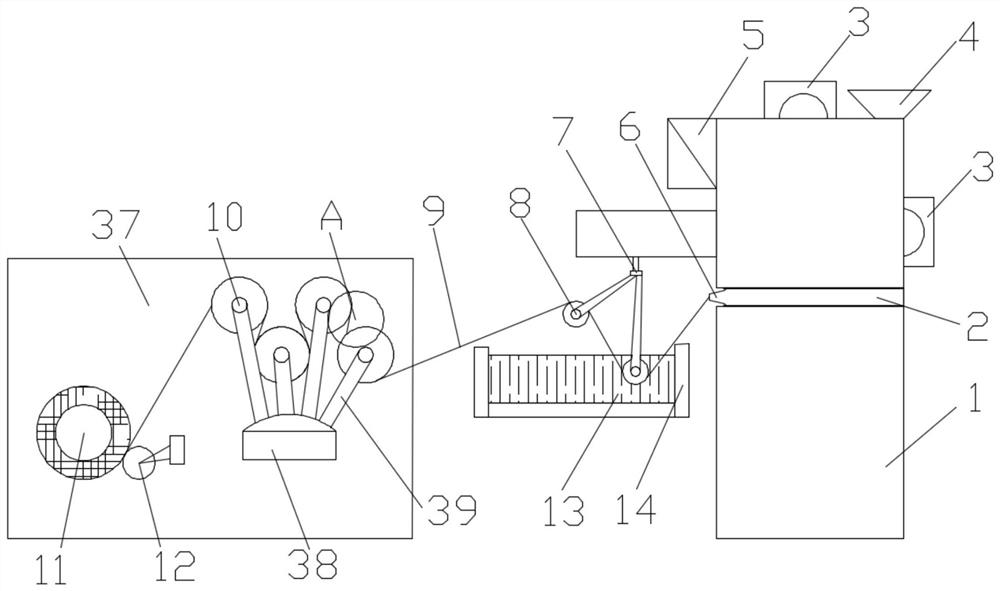

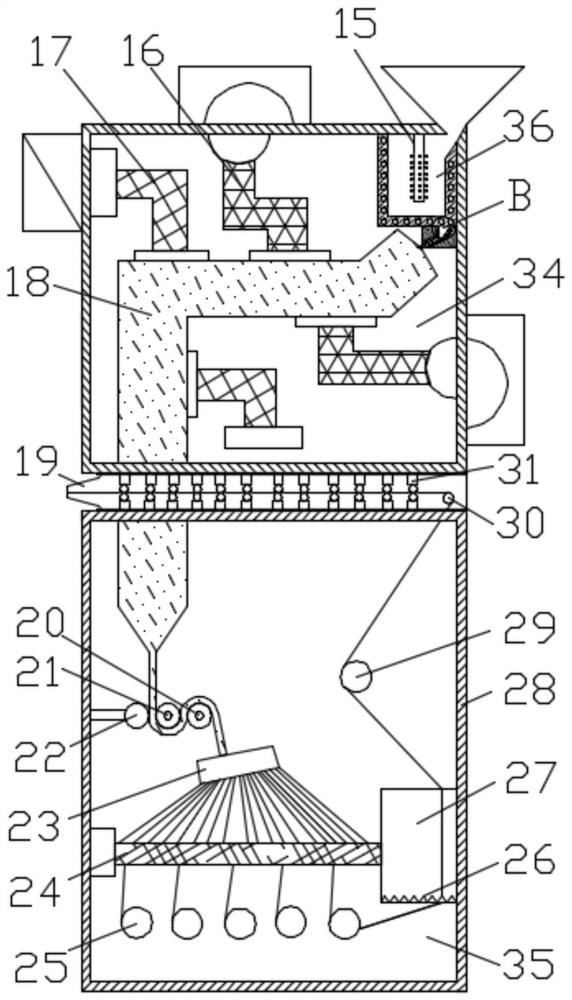

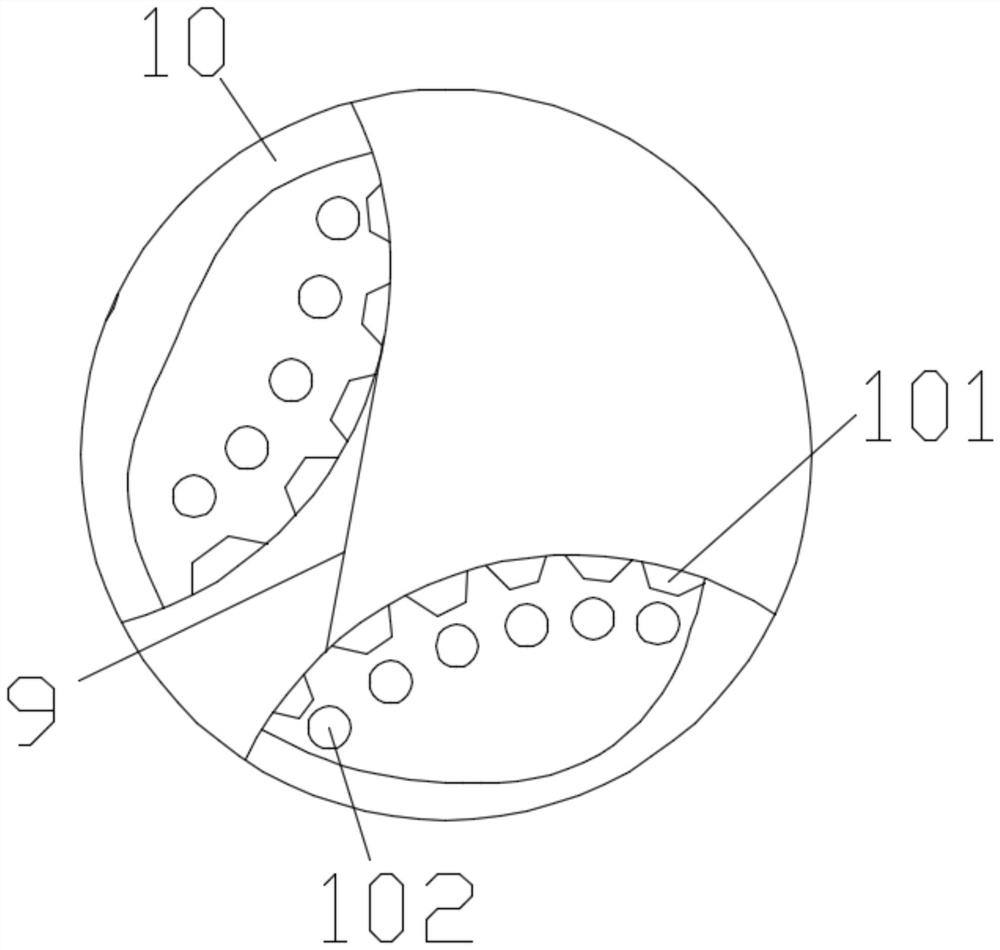

[0029]Referring to the accompanying drawings: a high-strength woven bag production device in this embodiment includes a wire drawing machine 1, a wire outlet chamber 2, a refrigerator 3, a material inlet 4, a heater 5, a wire outlet 6, and a winding roller 11. Wire guide 12 and casing 28, the outer side of the wire drawing machine 1 is a casing 28, the refrigerator 3 is fixedly connected to the upper end and the right end of the casing 28 of the wire drawing machine 1, and the heater 5 is fixedly connected to the wire drawing machine 1 The left end and the rear end of the housing 28, the feed port 4 is fixedly connected to the upper end of the housing 28 of the wire drawing machine 1, the wire outlet chamber 2 is connected to the middle end of the wire drawing machine 1, and the left end of the wire outlet chamber 2 is connected to the wire outlet 6. The left side of the wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com