Control method of pulsator washing machine and pulsator washing machine

The technology of a pulsator washing machine and its control method, which is applied to the control of pulsator washing machines and the field of pulsator washing machines, can solve the problems of easy water splashing on the cover and abrasion of down clothes, etc., so as to avoid floating, increase wetting, and ensure the rinsing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] At present, the washing machine has a down washing program for washing down clothes. In the process of washing down clothes, the washing machine needs to add a gland to press the down clothes, so as to prevent the down clothes from floating up during the washing process of down clothes, which will affect the washing effect. However, due to the setting of the gland, a structure is required to fix the gland, which causes the structure of the washing machine to be complicated; and in the washing process, the down clothing rubs against the gland, which will cause the down clothing to wear to a certain extent. In addition, during the water intake process, there is a gland, which is prone to water splashing and affects user experience.

[0038] In order to solve the above problems, this embodiment provides a control method for a pulsator washing machine, which includes the following steps: During the water intake process, the washing tub is in a dehydration state, and when th...

Embodiment 2

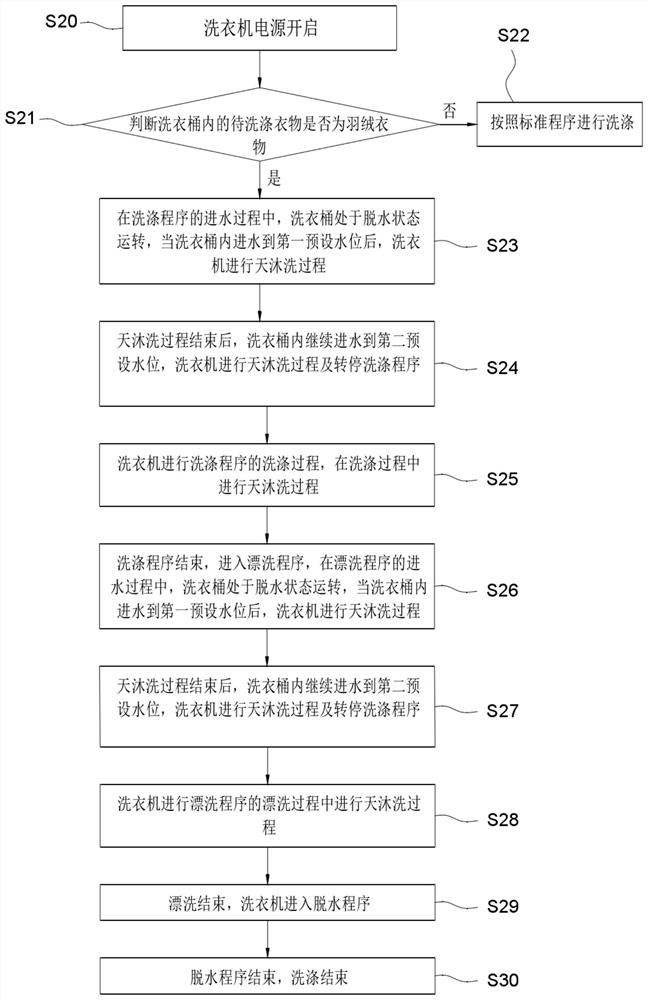

[0043] This embodiment provides a control method for a pulsator washing machine, and this embodiment is a further improvement on the basis of the first embodiment. Such as figure 1 As shown, the control method of the pulsator washing machine includes the following steps:

[0044] S20, the washing machine is powered on.

[0045] S21. Before the water enters, it is judged whether the laundry to be washed in the washing tub is down clothing.

[0046] By judging whether the clothes to be washed in the washing tub are down clothes before entering the water, targeted cleaning can be performed according to the type of clothes to be washed.

[0047] Optionally, during the process of putting the laundry into the washing tub, the code scanning component can scan the code of the laundry to identify the material of the laundry recorded on the barcode of the laundry. The camera component can also be used to photograph the clothes to be washed for comparison and confirmation of the mater...

Embodiment 3

[0074] This embodiment provides a pulsator washing machine that adopts the control method for the pulsator washing machine in the first or second embodiment above. The pulsator washing machine adopts the control method of the pulsator washing machine mentioned above, which avoids the floating of the down clothes, ensures the washing effect, solves the water resources, does not need to set a gland, simplifies the structure of the washing machine, avoids wear and tear on the down clothes and avoids water splashing .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com