Modeling method for modular splicing type complex terrain

A technology of complex terrain and modeling method, applied in the direction of hydraulic model, etc., can solve the problems such as non-reusable markers, increase of model making errors, destruction of original terrain, etc. Terrain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

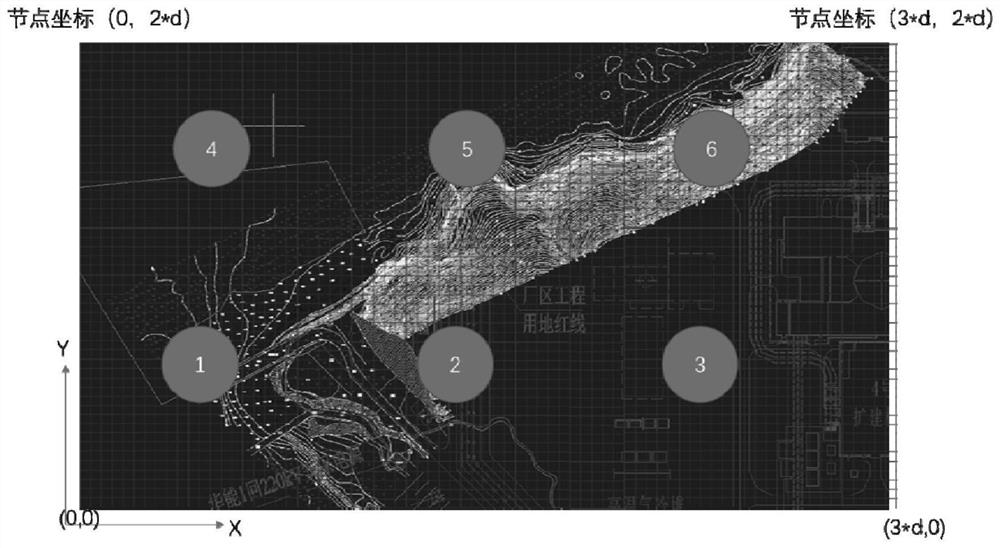

[0039] A modeling method of modular splicing complex terrain, comprising the following steps:

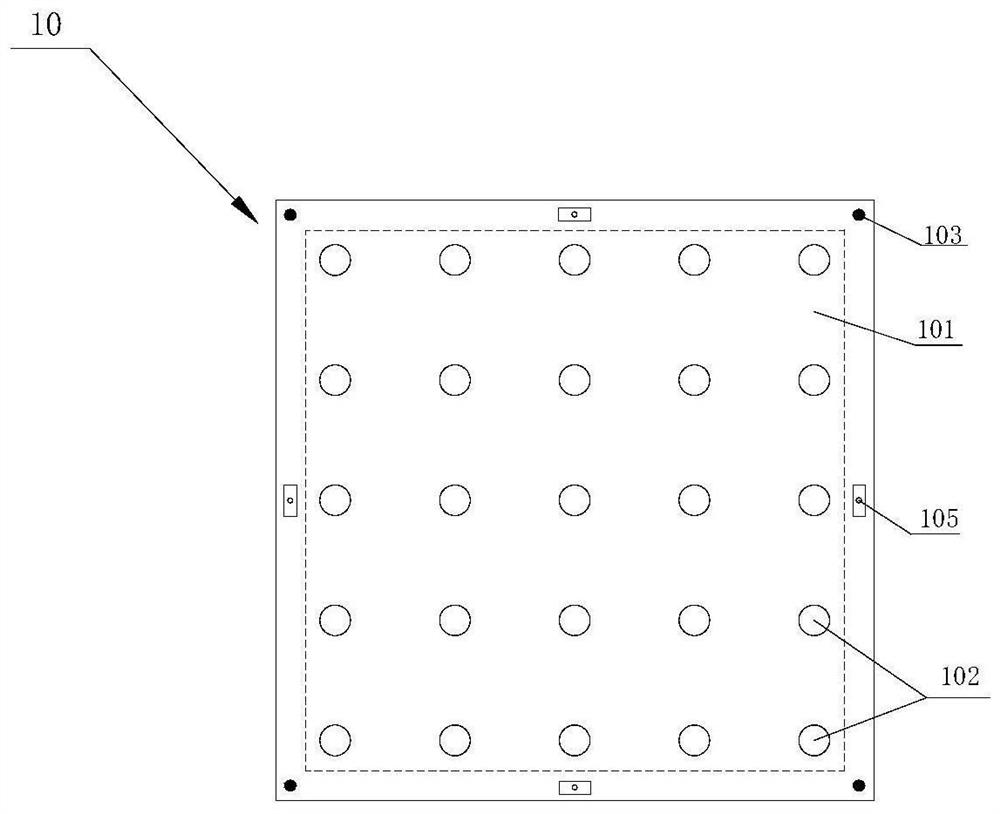

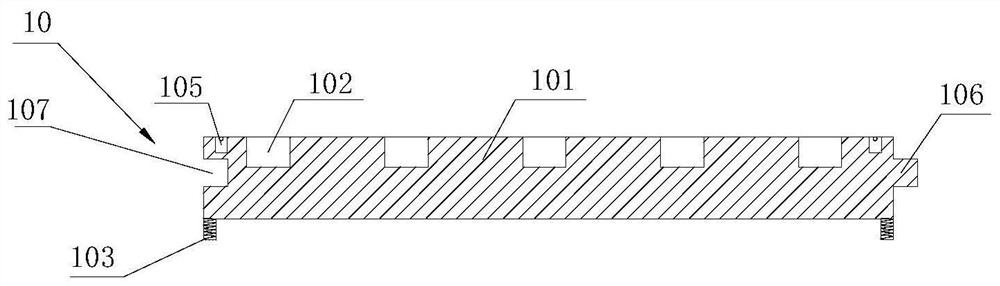

[0040] S1. First, make a modular modeling unit for backup, please refer to figure 2 and Figure 6 , the modular modeling unit 10 includes a square base base 101, the upper and lower surfaces of the base base are horizontal reference planes, and n×n card slots 102 are equidistantly arranged on the upper surface of the base, and the base base Adjustable height knobs 103 are installed at the four corners of the lower surface; it also includes a telescopic ruler 104 for accurately simulating the height of the terrain; the telescopic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com