Safety maintenance structure for concrete pool

A technology for concrete and water pools, which is applied in the configuration of water supply pools, building maintenance, water supply devices, etc. It can solve the problems of water leakage and no way to monitor it, and achieve the effect of convenient monitoring and high maintenance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following is attached Figure 1-4 The application is described in further detail.

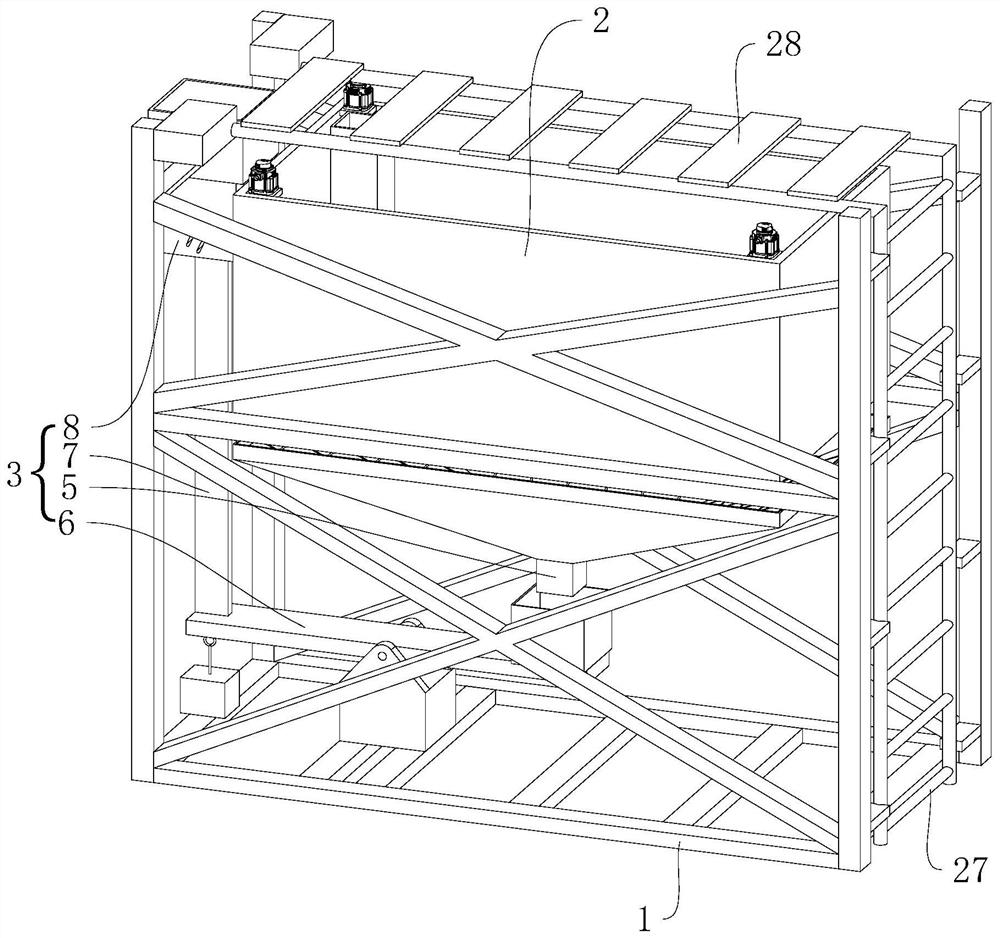

[0037] see figure 1 , a concrete pool safety maintenance structure, including a support frame 1 built in the ground, a pool body 2 buried in the ground and located on the top of the support frame 1, and an inspection component 3 located at the lower end of the pool body 2.

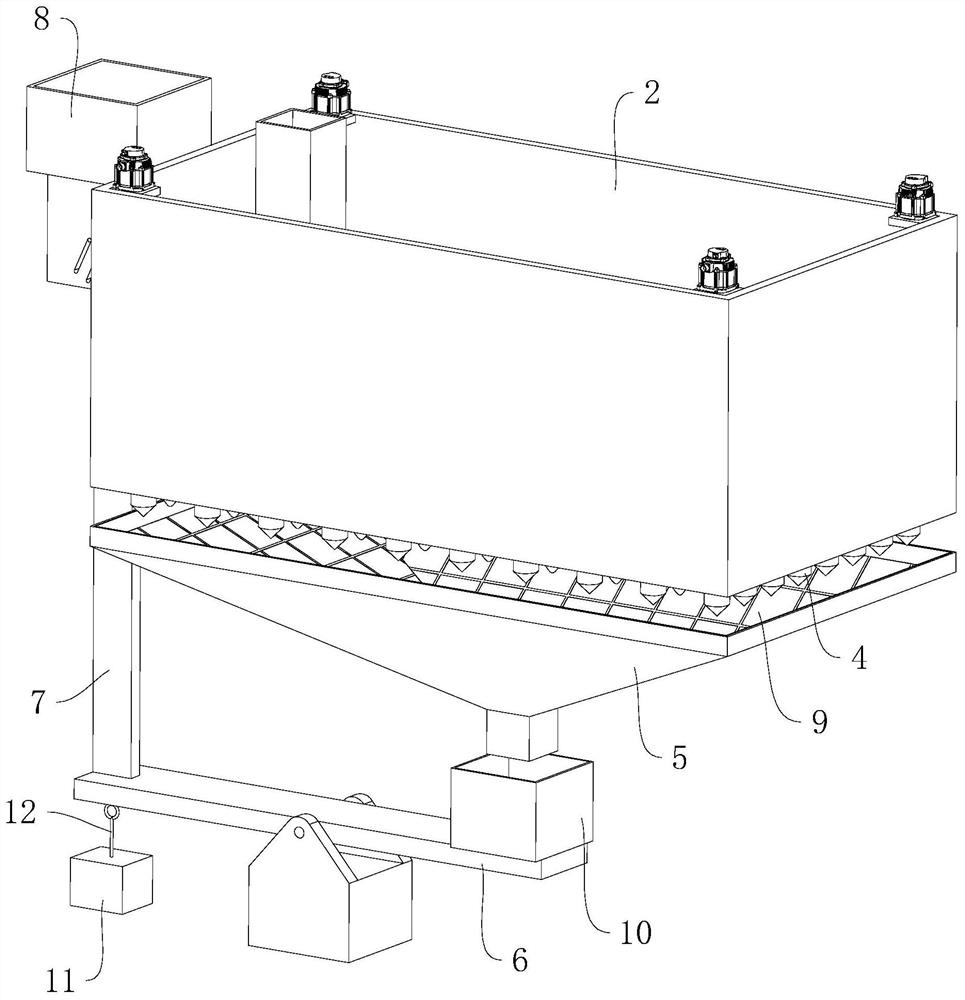

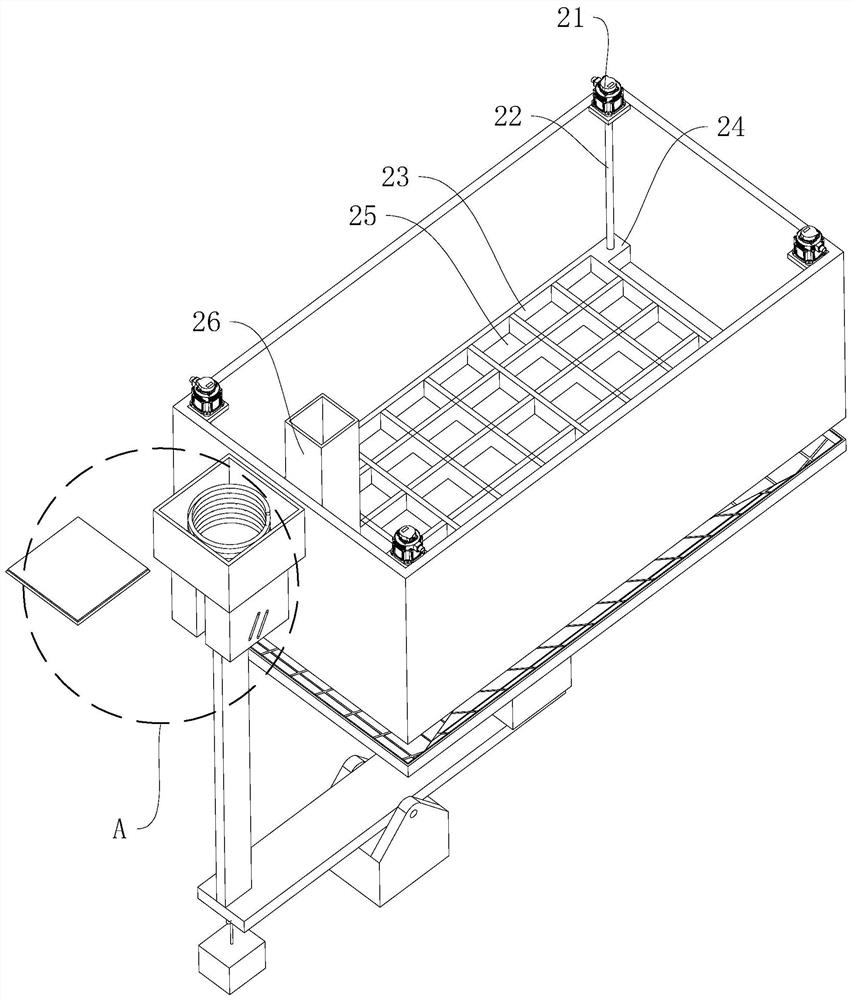

[0038] see figure 1 and figure 2 The pool body 2 is made of reinforced concrete and is vertically hoisted by a crane and placed on the support frame 1. The pool body 2 is square as a whole, and its opening is vertically opened from the upper end. The lower end of the pool body 2 is integrally cast and formed. A plurality of vertically downward water guide cones 4, when the bottom wall of the pool body 2 leaks, the leaked water flow can directly flow down along the nearest water guide cone 4.

[0039] The maintenance assembly 3 includes a water leakage collection bucket 5, a lifting plate 6, a connecting plat...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap