Butt joint inserting type flue gas exhaust pipeline

A plug-in, gas pipeline technology, applied in vertical pipelines, building components, buildings, etc., can solve the problem that the product yield and product quality are difficult to guarantee, inconvenient for hoisting, transportation, construction and installation, and the overall exhaust gas pipeline of a single section. High problems, to achieve the effect of high construction efficiency, not easy to break, and product quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

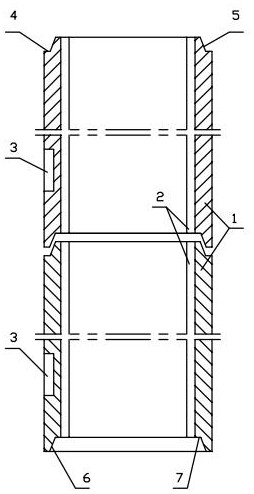

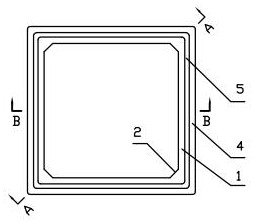

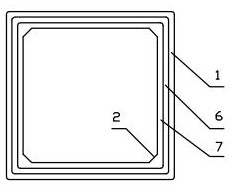

[0042] Referring to the accompanying drawings, the butt plug-in exhaust gas pipeline includes the exhaust gas pipeline body 1 that can be butted up and down with each other, and the upper and lower ends of each section of the smoke exhaust pipeline body 1 are provided with corresponding plug-in structures. , the flue gas exhaust pipe body 1 located relatively above and the flue gas exhaust pipe body 1 adjacent to the lower side are plugged together according to the plug-in structures correspondingly arranged at the upper and lower ends of themselves.

[0043] refer to figure 1 — Figure 5 The plug-in structure includes a flue gas exhaust pipe body 1, the upper end of the flue gas exhaust pipe body 1 forms a tenon inwardly and upwardly along its top wall, and the relative lower end of the flue gas exhaust pipe body 1 forms a tenon groove inwardly and upwardly along its bottom wall. The tenon includes a butt joint top edge 4 horizontally inward along the outer wall of the flue ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap