Concrete crack bioremediation method

A technology of bioremediation and concrete, which is applied in building maintenance, building construction, construction, etc., to achieve the effect of environmental friendliness and strength recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The present invention provides a method of concrete crack repair, the method by sequentially immersing the concrete crack in the concrete solution, urea solution, and soluble calcium salt solution, excess liquid from the concrete crack, and after 1 hour, Repeated operation to repair concrete cracks.

[0031] The concentration of the soluble calcium salt solution was 1 mol / L.

[0032] The concentration of the urea solution was 1 mol / L.

[0033] The Bacillus solution, urea solution, and soluble calcium salt solution are the same.

[0034] The soluble calcium salt solution is CA (NO 3 ) 2 Solution.

[0035] The culturing temperature of the Bacillus bacillus solution was 20 ° C, and the culture time was 16 hours.

Embodiment 2

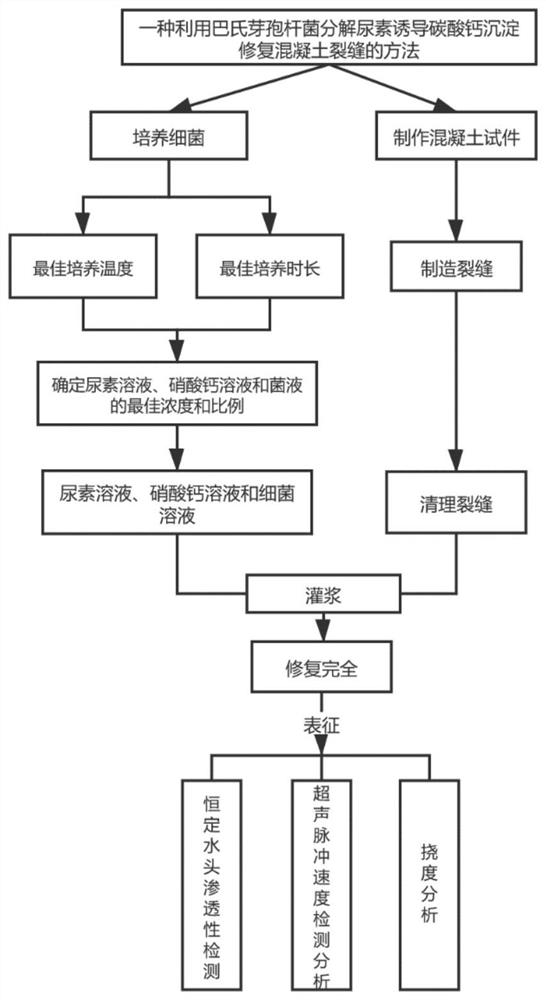

[0037] The production process flow used in the present invention is figure 1 As shown, the technical solutions employed are as follows:

[0038] Bacterial activation culture: Pakunar bio-purchased Pastelioprostophilus, activation, inverted flat plate, expanded culture;

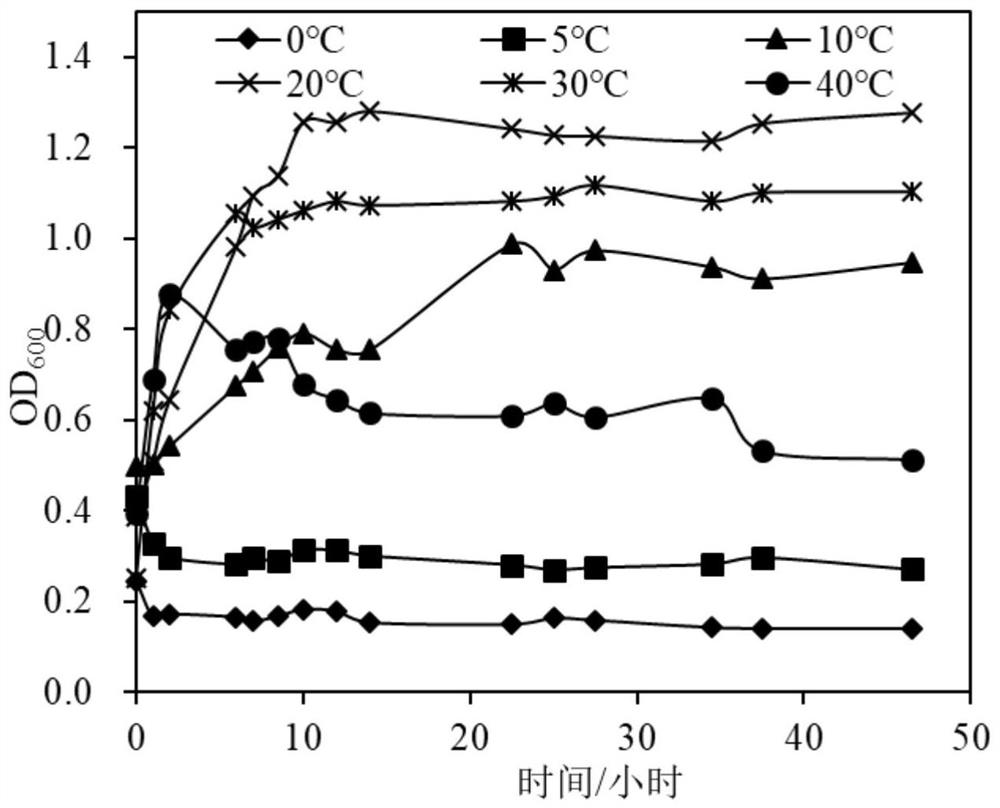

[0039] Determine the optimum temperature and optimal culture of bacterial growth: Culture Bacillus in 6 temperatures (0 ° C, 5 ° C, 10 ° C, 20 ° C, 30 ° C and 40 ° C), plotted growth curves to obtain bacteria The best culture temperature is 20 ° C and the best culture time is 15-18 hours, and the result is figure 2 Indicated;

[0040] Determine the optimum concentration and proportion of urea solution and calcium nitrate solution: design three groups of experiments, the first group of 10 ml of 1 mol / L urea solution, 10ml 1 mol / L CA (NO 3 ) 2 Solution and 10 ml bacterial solution, the second group is 10 ml of 2 mol / L urea solution, 10 ml of 2 mol / L of CA (NO 3 ) 2 Solution and 10 ml bacterial solution, the ...

Embodiment 3

[0049] Bacillus Activation of Bacillus Bacillus: Italy Bacillus Pakistani Pakistani Pakistanus Bacillus Freescent Fluid, Activated, Inverted Tablet, Expanded Culture;

[0050] Bacillus Bacillus were cultured at 20 ° C for 15 hours;

[0051] Urea solution, CA (NO 3 ) 2 The best reaction ratio of the solution and bacterial solution is: the first group of 10 ml 1 mol / L urea solution, 10 ml of 1 mol / L of CA (NO 3 )2 Solution and 10 ml of bacterial solution;

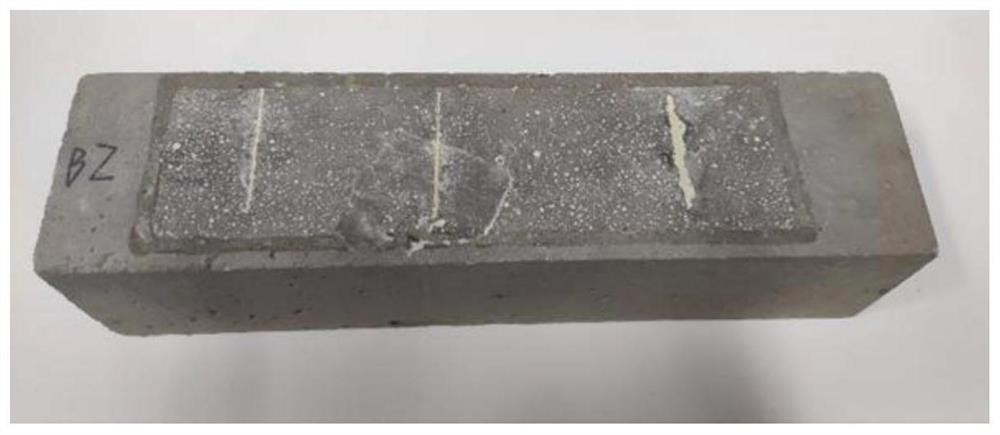

[0052] Clean concrete crack: First put the concrete test piece under the faucet, to remove some of the debris in the crack, then use the plug to scratch some other debris, and then place the concrete specimen in the faucet, and finally at room temperature. Dry; paste the waterproof tape at the bottom of the crack. The action of waterproof tape is to pass excess water, and the repair material is retained in the crack;

[0053] Urea solution, CA (NO 3 ) 2 Solution and bacterial solution grout: inject the bacterial solution to b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com