Exhaust pipe and exhaust cavity assembly for rotor compressor

A technology of rotor compressor and exhaust pipe, which is applied to components of pumping devices for elastic fluid, pump components of rotary piston type/swing piston type, mechanical equipment, etc. Problems such as air cavity and large noise can reduce exhaust pulsation and noise, extend the running path, and reduce the flow rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

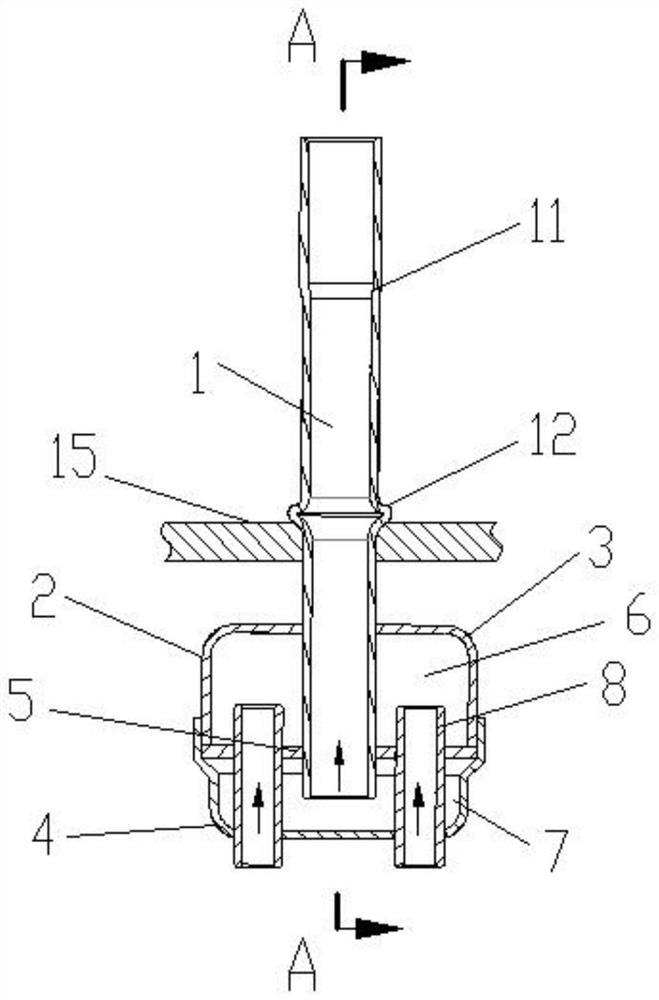

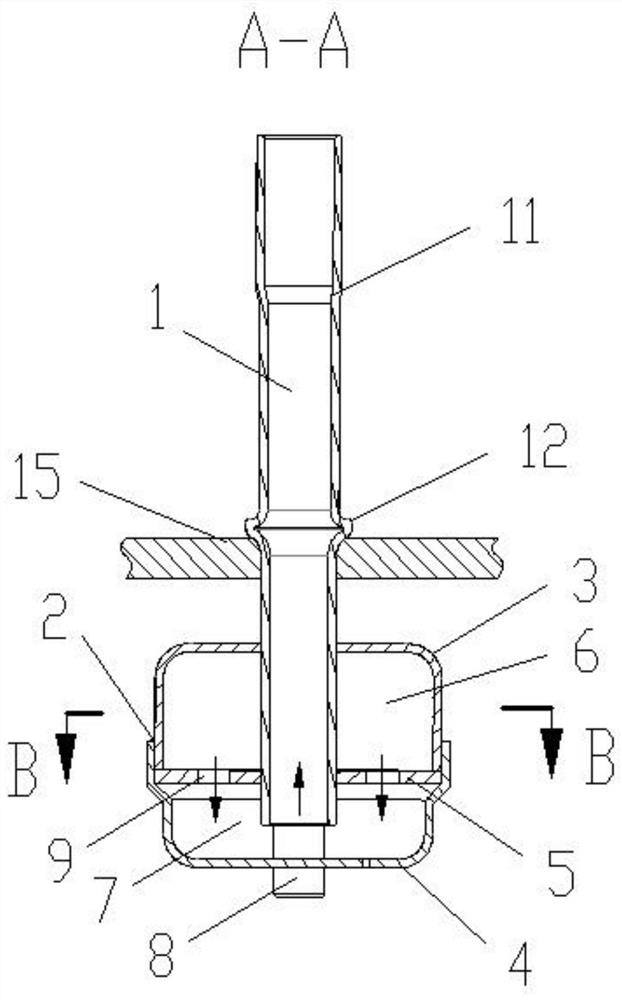

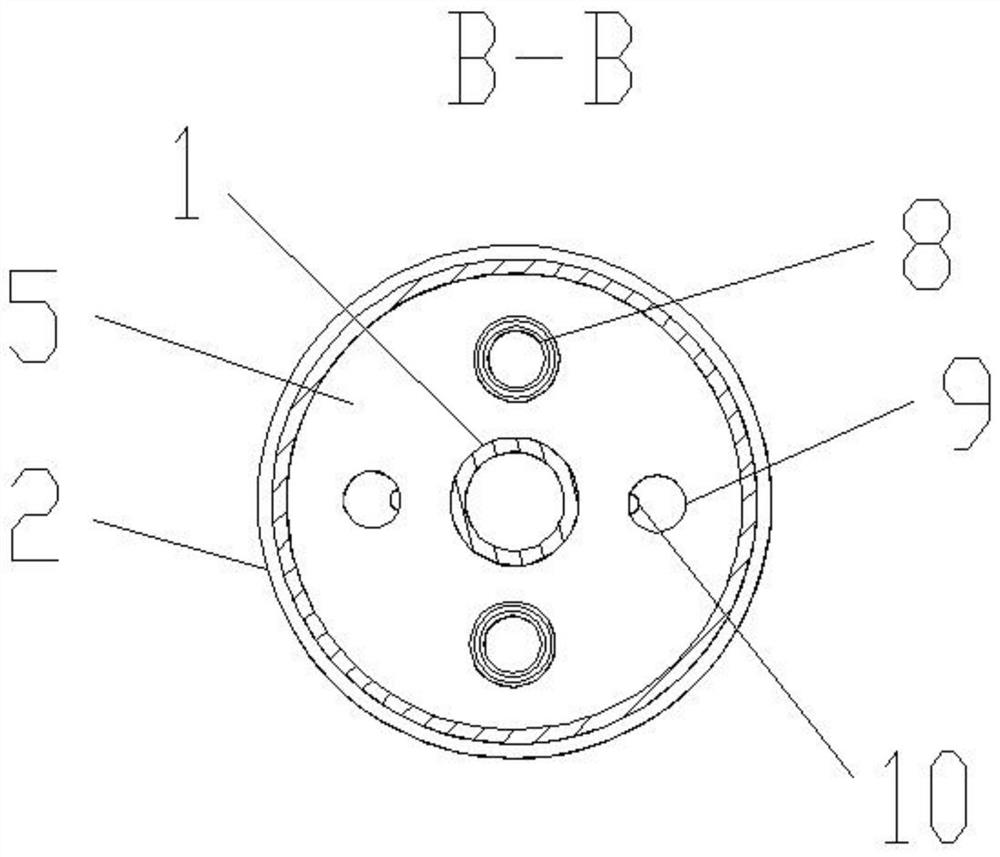

[0041] Such as Figure 1-4 As shown, an exhaust pipe and exhaust chamber assembly for a rotary compressor, the exhaust chamber 2 includes a first end cover 3 and a second end cover 4 fixedly connected, the first end cover 3 A partition 5 is fixed between the second end cover 4 and the space formed by the partition 5 and the first end cover 3 constitutes a first cavity 6, and the partition 5 and the second end cover The space formed by the cover 4 constitutes a second cavity 7, and two air intake pipes 8 are connected between the partition plate 5 and the second end cover 4, and the air intake pipes 8 communicate with the first cavity 6 Outside the exhaust chamber 2, two vent holes 9 are opened on the partition 5, and the air inlet end of the exhaust pipe 1 runs through the first end cover 3 and the partition 5, so The intake end of the exhaust pipe 1 is located in the second cavity 7 , and the exhaust pipe 1 passes through and is connected with the casing 15 of the compressor...

Embodiment 2

[0059] Such as Figure 5 As shown, this embodiment is an exhaust pipe and exhaust cavity assembly for a rotary compressor, which is further optimized on the basis of Embodiment 1:

[0060] Further, the partition plate 5 is provided with a boss 13 located on the periphery of the intake end of the exhaust pipe 1 , and two layers of filter screens 14 are fixed inside the boss 13 . The fixing method can be welded, glued or clamped.

[0061] By arranging the boss 13 and the strainer 14, the oil liquid is better prevented from being sprayed out of the exhaust pipe 1, and the blocked oil liquid will flow back into the compressor from the oil leakage hole 10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com