A vertical screw squeeze juice extractor with fast juice output

A screw extrusion and juicer technology, which is applied to household machinery, kitchen utensils, household utensils, etc. for filtering food, can solve the problems of inconvenient operation for users, unsatisfactory juice yield, difficult installation and alignment, etc., and achieves simplified structure and Production process, guaranteeing juice yield and juice efficiency, and the effect of high juice yield and juice efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

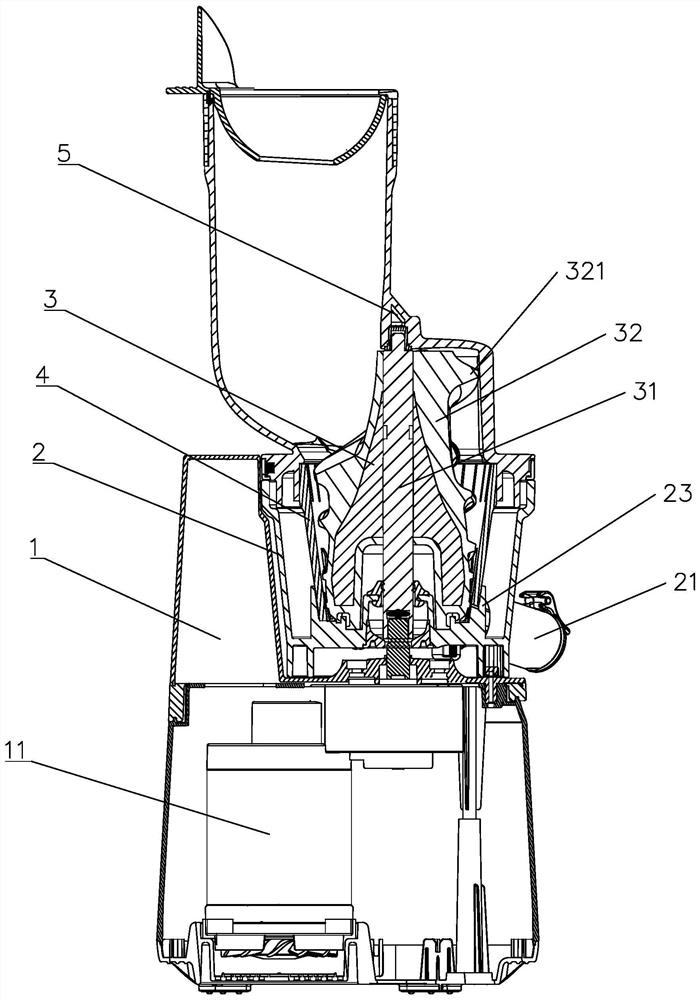

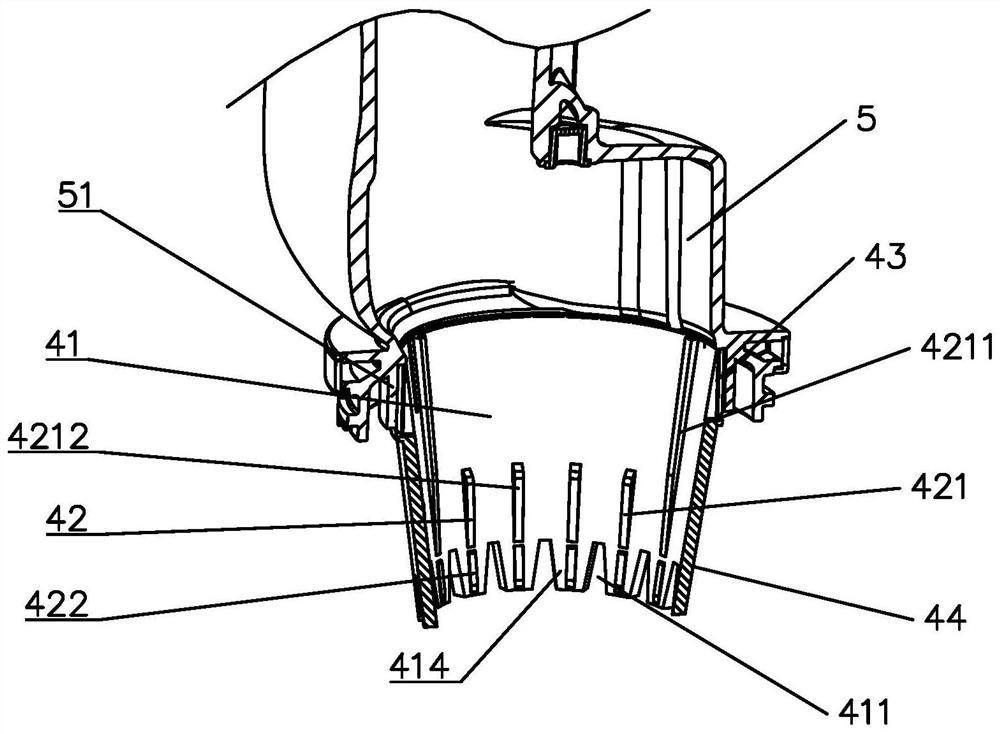

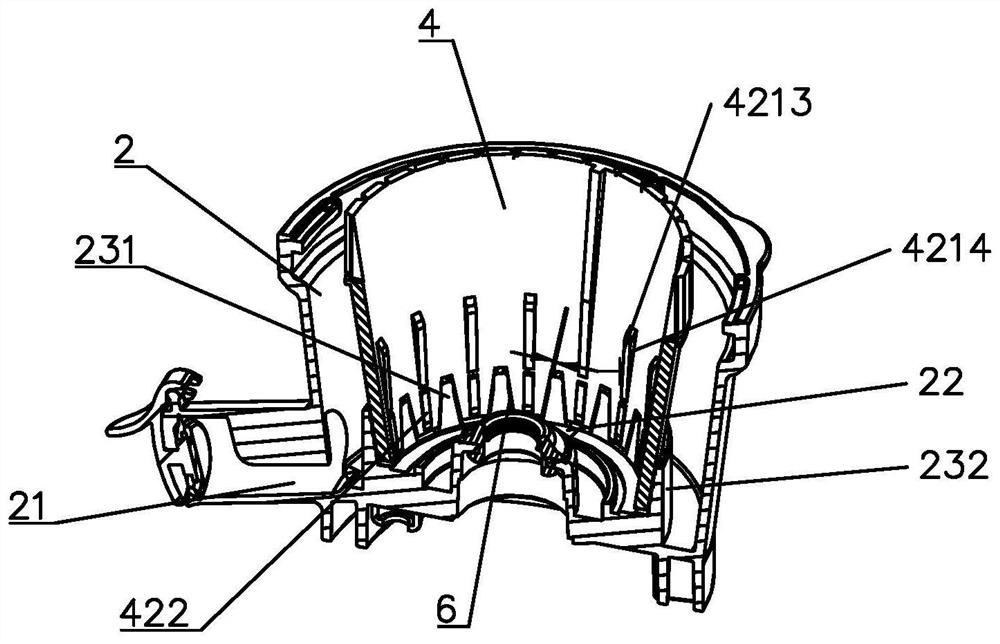

[0045] Such as Figure 1 to Figure 5 As shown, a vertical screw squeeze juicer with fast juice output includes a machine base 1, a juice collection chamber 2 arranged on the machine base, a screw 3 longitudinally arranged in the juice collection chamber, and a cover on the juice collection chamber On the top cover 5, the juice collecting cavity is provided with a juice outlet 21 and a slag outlet 22, a motor 11 is provided in the base, the screw includes a screw shaft 31 and a screw body 32, and the screw body is provided with a helix 321, which collects The juice cavity includes a bottom wall and a side wall, wherein, the screw rod is also sleeved with an extruding cylinder 4, which is detachably arranged relative to the juice collecting chamber, and the extruding cylinder includes a cylindrical shape with upper and lower openings The body 41 is also provided with ribs 42 that cooperate with the screw to extrude the material, the bottom wall of the juice collection chamber is...

Embodiment 2

[0065] Such as Image 6 As shown, this embodiment optimizes the structure of the extrusion cylinder on the basis of the first embodiment.

[0066] In this embodiment, the extrusion cylinder includes a straight section 43 and a cone section 44 from top to bottom, an upper filter part is provided on the upper part of the extrusion cylinder, and the positioning ring is at least partially covered on the outside of the upper filter part , the upper filter part includes a plurality of upper filter slits 413, and the upper filter slits are circumferentially arranged on the straight barrel section 43, so as to facilitate local thickening of the wall thickness of the body and prevent cracking or cracking at the upper filter slits 413. At the same time, the straight section can further expand the inner space of the extrusion cylinder, which is beneficial to the improvement of feeding efficiency. Specifically, the width of the upper filter slit 413 is W, 0.3mm≤W≤5mm, so that a large amo...

Embodiment 3

[0073] Such as Figure 7As shown, the difference between the present embodiment and the second embodiment lies in that the structure of the lower filtering gap is different.

[0074] The insertion part of the extrusion cylinder includes a plurality of protrusions 414 arranged at the lower part of the extrusion cylinder at intervals in the circumferential direction, and the lower filter gap 6 is formed between adjacent protrusions, and the fitting on the bottom wall of the juice collection cavity The upper part includes a positioning boss 4141 arranged at the bottom end of the protrusion, and a positioning groove 24 corresponding to the positioning boss 4141 is provided on the upper circumference of the bottom wall of the juice collection chamber, and the positioning boss is inserted into the positioning groove The extrusion cylinder is positioned inside, which is equivalent to replacing the limit ring with the positioning groove, which greatly simplifies the structure of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com