One of the upper filtering screw squeezing juicer

A technology of screw extrusion and juicer, which is applied in household machinery for filtering food, kitchen utensils, household utensils, etc. It can solve the problems affecting the juice yield, the quality of the juice, and the taste of the juice.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

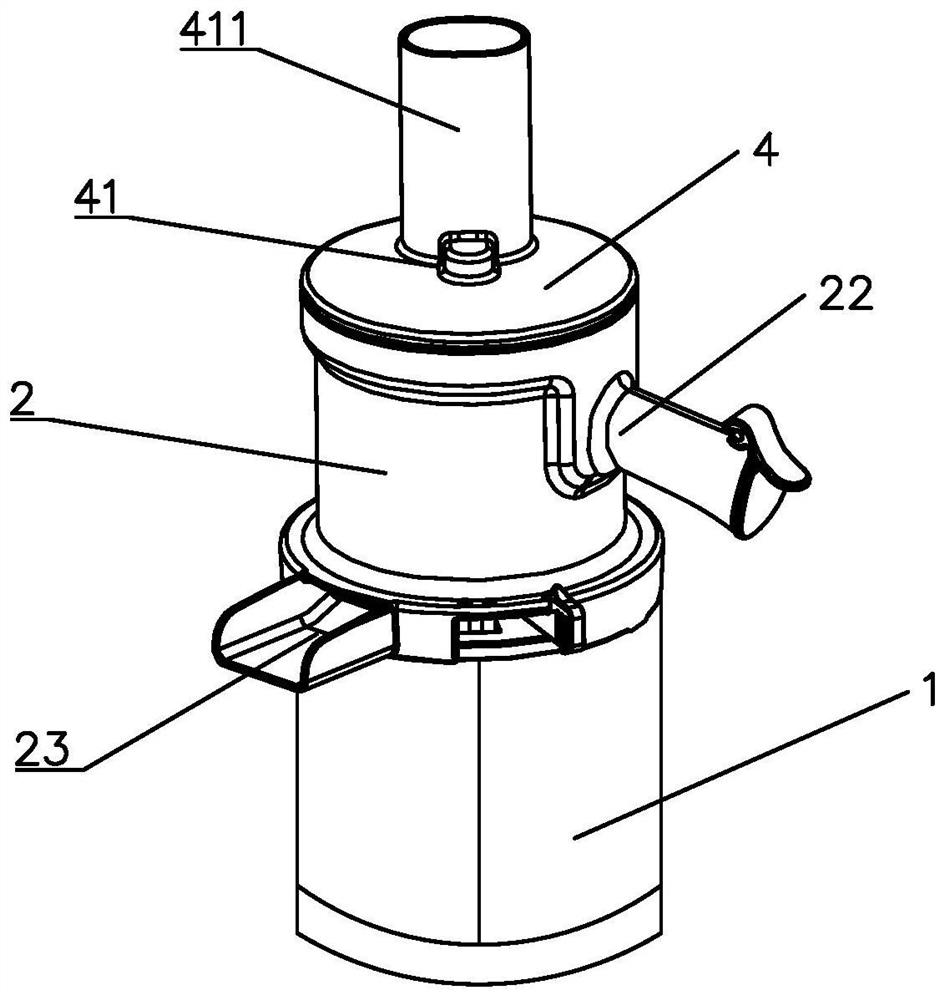

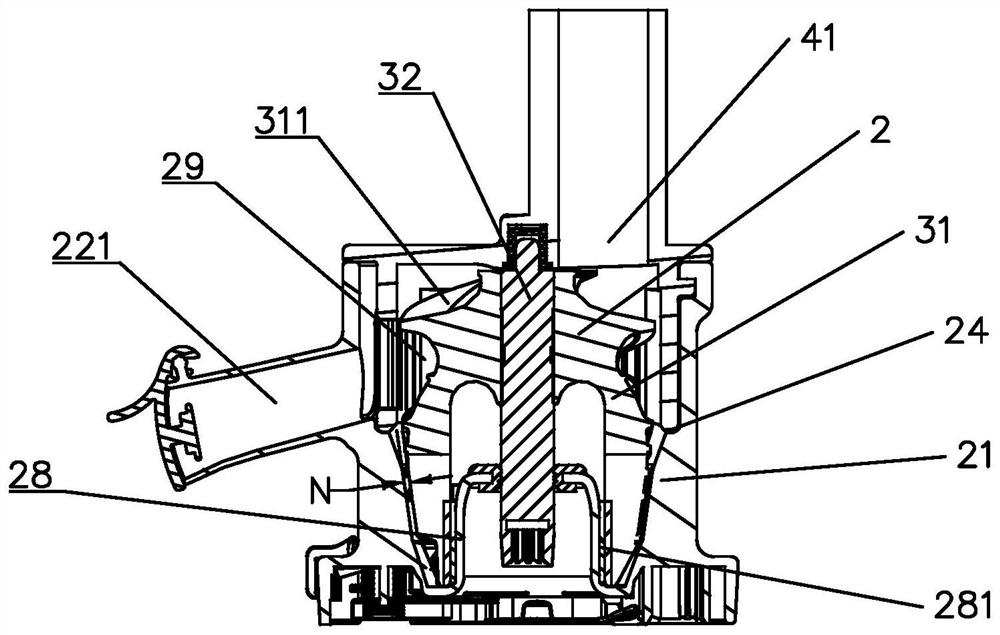

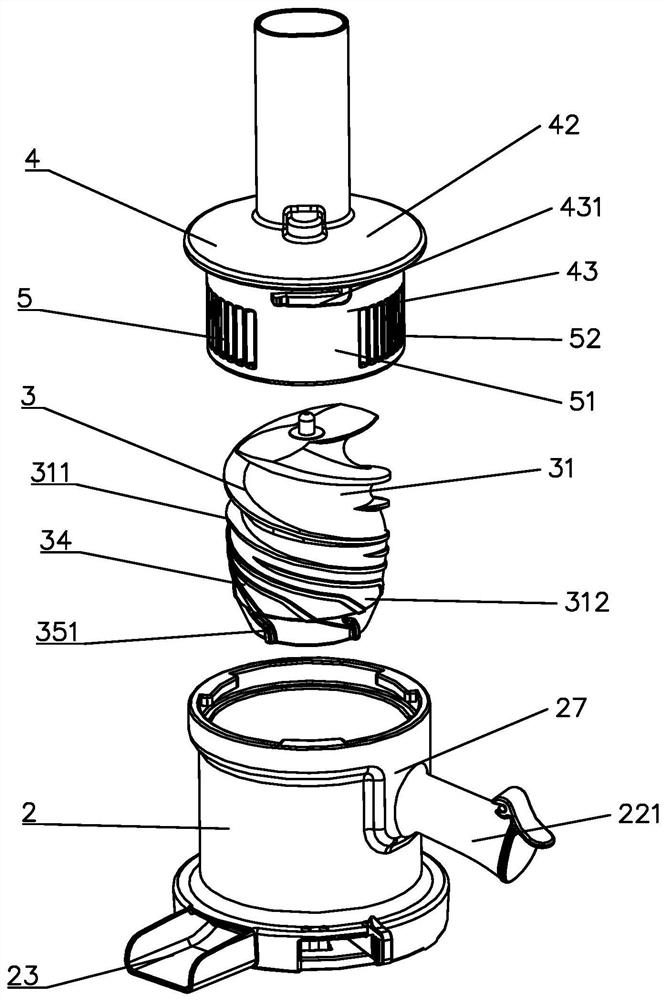

[0048] like Figure 1 to Figure 7 As shown, an upper filtering vertical screw squeeze juicer includes a base 1, a pressing assembly connected with the base, and the squeezing assembly includes a juice collecting cavity 2 connected with the base, and a juice collecting cavity 2 longitudinally arranged in the juice collecting cavity The screw 3, and the upper cover 4 covering the upper port of the juice collecting chamber, the upper cover includes a top wall 42 and a side wall 43, a feeding port 41 is arranged on the top wall of the upper cover, a motor is arranged in the base, and the screw includes a screw The screw body 31 and the screw shaft 32, the screw body is provided with a screw 311, wherein the screw body includes a feeding section 33, a grinding section 34 and a slag discharge section 35 from top to bottom. 21. The squeezing and pulverizing part 21 cooperates with the screw grinding section 34 to form a squeezing and pulverizing gap. The upper part of the juice colle...

Embodiment 2

[0071] like Figure 8 As shown, the difference between this embodiment and the first embodiment is that the structure of the filter part is different.

[0072] In this embodiment, the filter part further includes a movable baffle 53, and the movable baffle 53 is movably arranged between the juice outlet and the filter baffle. The movable baffle 53 cooperates with the filter baffle to change the effective filtering area, so as to adjust the taste of the filtered juice. The inner surface of the movable baffle 53 is matched with the outer surface of the filter baffle 51. The filter holes on the filter baffle 51 cooperate with the movable baffle to form a juice filtration gap. The juice filtration gap can be adapted according to the adjustment position of the movable baffle. Change, the value of the filter gap is D. In this embodiment, the filter holes on the filter baffle 51 and the movable baffle 53 are longitudinally arranged, and the range value of the filter gap that can be ...

Embodiment 3

[0079] like Figure 9 As shown, the difference between this embodiment and the first embodiment is that the structure of the filtering part is different.

[0080] In this embodiment, a fixed baffle plate 54 is arranged at the lower part of the juice outlet, and a filter hole 52 is arranged on the fixed baffle plate. After the upper cover is installed in place, the filter baffle plate 51 is located above the fixed baffle plate 54. The plate 51 and the fixed baffle 54 cover the juice outlet 22 together, and the filter holes 52 on the filter baffle 51 and the fixed baffle 54 cooperate up and down to form the juice filtration gap, so that the juice outlet area of the juice outlet is formed. The changes are more diverse, and the area ratio of the fixed baffle and the filter baffle covering the juice outlet can also be adjusted according to the actual situation. like Figure 9a As shown, the filter holes on the filter baffle and the movable baffle have the same pore size and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com