Capillary core capillary performance detection device and method based on electric signal method

A detection method and capillary core technology, which are used in measurement devices, material analysis by electromagnetic means, instruments, etc., can solve the problems of complex, inapplicable, and not many systems, and achieve high precision, easy operation, simple device and high precision. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to understand the technical essence and beneficial effects of the present invention more clearly, the applicant will describe in detail the following examples, but the descriptions of the examples are not intended to limit the solutions of the present invention. Equivalent transformations that are only formal but not substantive should be regarded as the scope of the technical solution of the present invention.

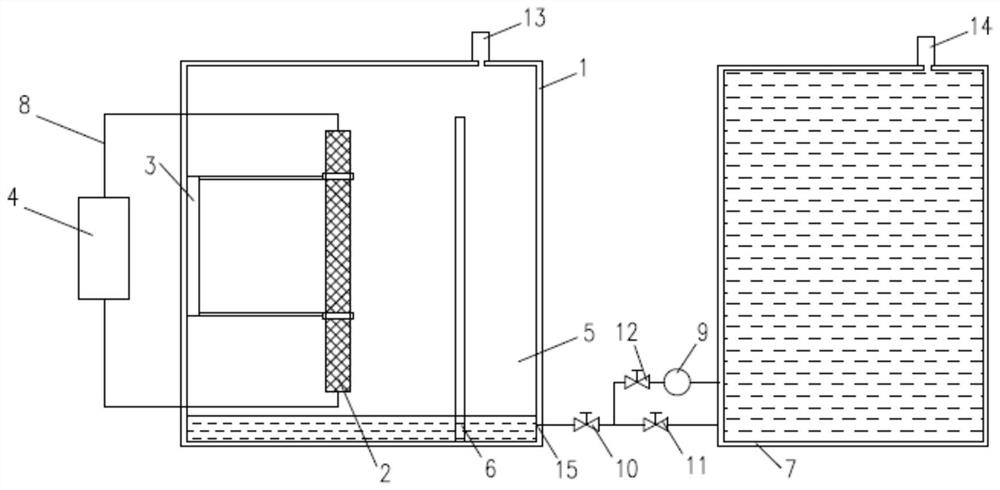

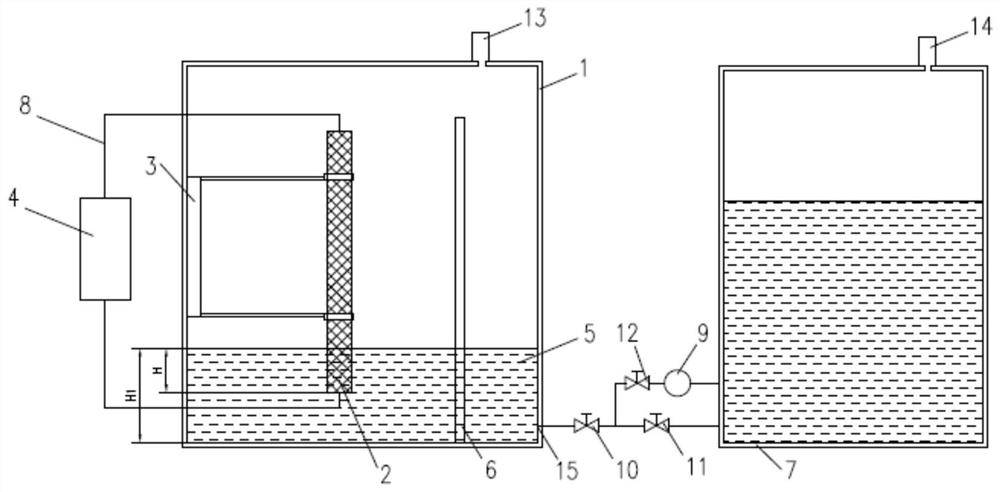

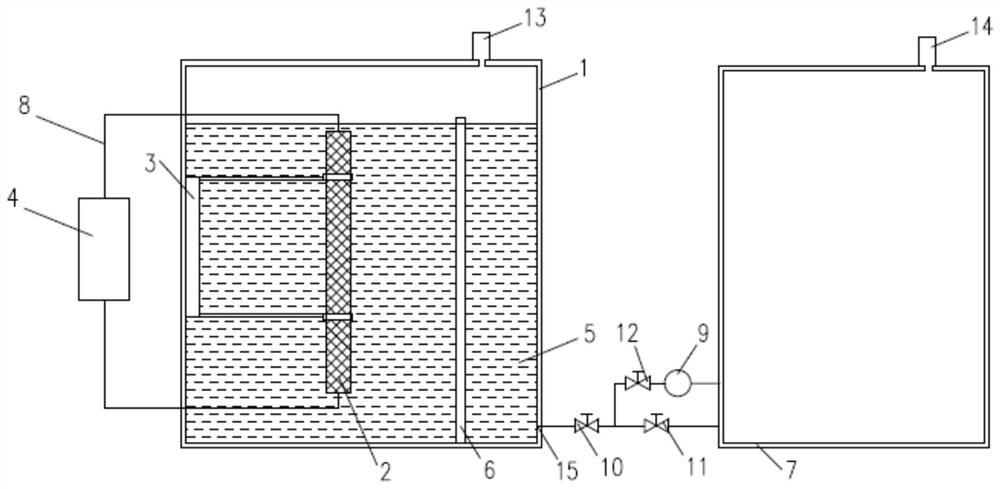

[0027] combine figure 1 , capillary performance testing device and method based on electrical signal method, the device consists of a test container 1, a capillary 2, a fixed frame 3, a resistance value measuring device 4, a liquid working medium 5, a partition 6, a liquid storage tank 7 , test cable 8, rehydration pump 9, liquid inlet valve 10, liquid return valve 11, rehydration 12, test container exhaust valve 13, liquid storage tank exhaust valve 14 and filling port 15. The capillary core 2 is installed on the fixed frame 3, the fixed frame 3 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com