A control method for realizing full-range soft switching of three-phase inverter four-quadrant operation

A technology of a three-phase inverter and a control method, which is applied in directions such as reversible conversion equipment, an output power conversion device, and conversion of AC power input into DC power output, etc., which can solve problems such as current discontinuity, and achieve switching The effect of high frequency, reduced volume and weight, and large current pulsation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

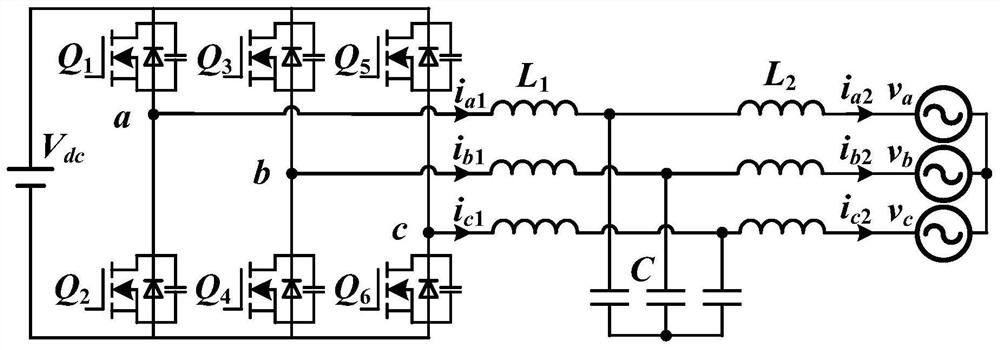

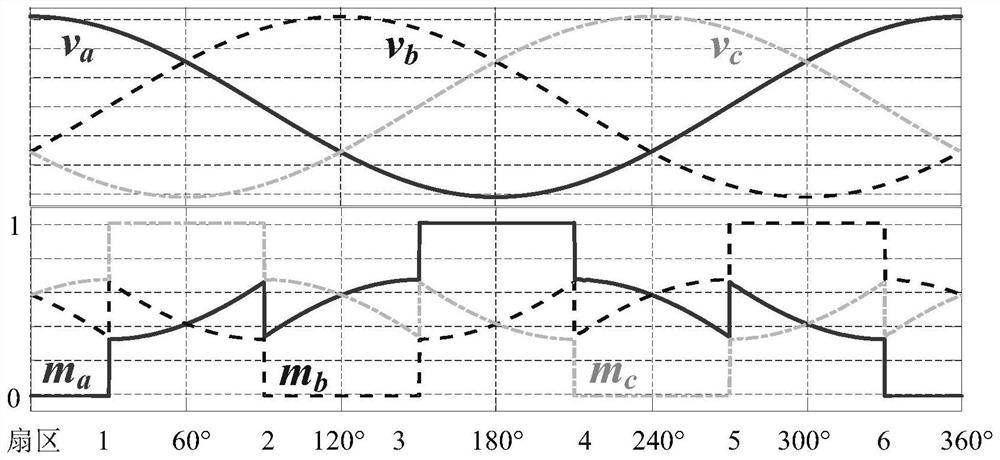

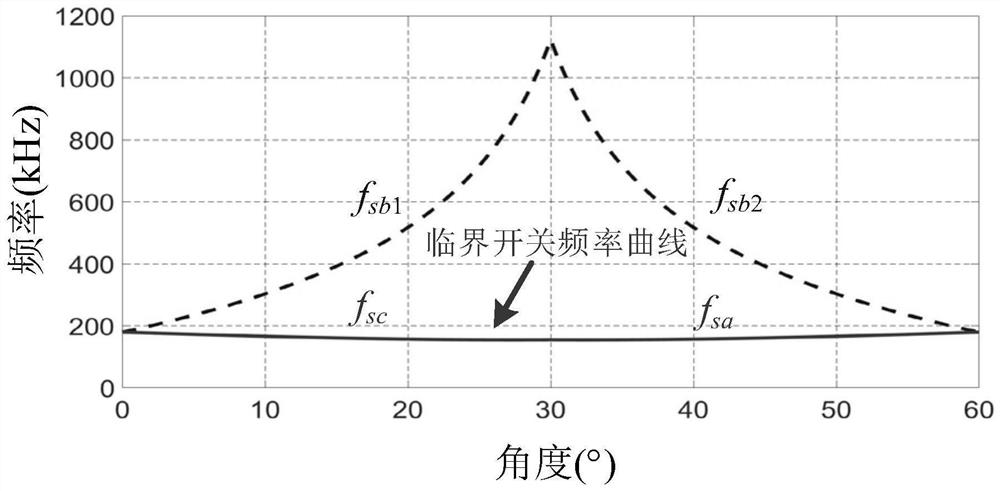

[0080] as Figure 1As shown in the present embodiment, a two-level three-phase voltage source inverter topology is selected, and the filter is an LCL filter; SiC MOSFET is selected for the switching device, and the model number is C3M0060065k; The battery is used as the DC power supply of the three-phase inverter, and the DC bus voltage V is used dc 400V; The load is the grid, and the RMS value of the load phase voltage is V rms It is 110V, rated at 3300VA, minimum switching frequency f smin 100kHz. When the three-phase inverter is in a non-unit power factor condition, the analysis under the inductive load and the capacitive load is similar, and the inductive load is used as an example.

[0081] The filter capacitance of the LCL filter is C, and the inductance on the AC side is L 2 , bias current I bias Take 2A and calculate the inverter side inductor L by equation (15). 1 is 10 μH; For filter capacitor C, the active current of the control flow filter capacitor C is less than 2% of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com