Anti-static degradable film for electronic packaging and preparation method of anti-static degradable film

An anti-static and degradable film technology, applied in the production of bulk chemicals, etc., can solve the problems of affecting the anti-static property of the film, decrease in biodegradability, uneven dispersion, etc., and achieve optimized anti-static performance, optimized degradation performance, preparation Process controllable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

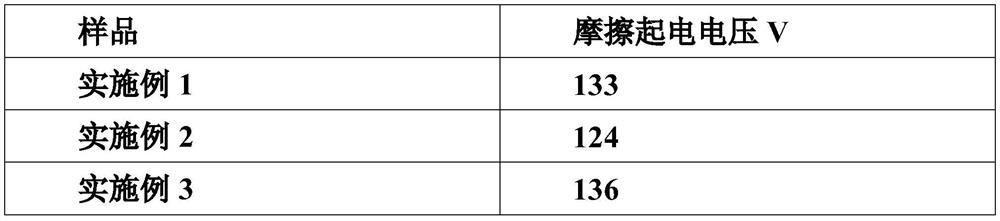

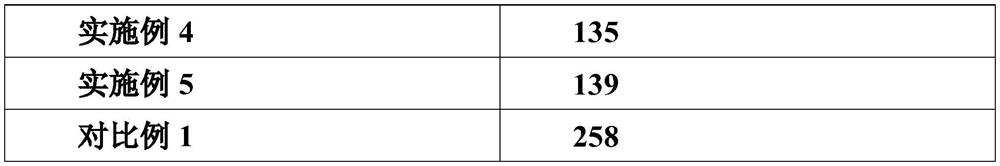

Examples

Embodiment 1

[0041] An antistatic degradable film for electronic packaging and a preparation method thereof, wherein the raw material components include the following parts by mass:

[0042] Matrix resin selects 50 parts of polydipropyl carbonate

[0043] 20 parts polylactic acid

[0044] Strengthening agent chooses 5 parts of ethylene-propylene copolymer

[0045] The coupling agent chooses 5 parts of titanate

[0046] Antistatic agents choose siloxane, polyamide and SnO 2 Oxide (ratio 1:1:2) 3 parts.

[0047] The preparation method is as follows:

[0048] 1) Prepare raw materials for mixing: weigh each component of the raw materials, including matrix resin, reinforcing agent, and coupling agent, put the above raw materials into the mixer, control the stirring rate to 1200r / min, and keep warm at 100°C for 5 minutes;

[0049] 2) Supercritical pretreatment: Send the masterbatch at the outlet of the mixer into the autoclave, then add the antistatic agent into the autoclave, and stir for 5 ...

Embodiment 2

[0054] An antistatic degradable film for electronic packaging and a preparation method thereof, wherein the raw material components include the following parts by mass:

[0055] Matrix resin selection ethylene terephthalate resin 45 parts

[0056] 20 parts polylactic acid

[0057] Strengthening agent selection ethylene-octene copolymer 3 parts

[0058] Coupling agent choose titanate 3 parts

[0059] The antistatic agent is 3 parts of siloxane, polyamide and CdO oxide (ratio 1:1:2).

[0060] The preparation method is as follows:

[0061] 1) Prepare raw materials for mixing: weigh each component of the raw materials, including matrix resin, reinforcing agent, and coupling agent, put the above raw materials into the mixer, control the stirring rate to 1100r / min, and keep warm at 90°C for 5 minutes;

[0062] 2) supercritical pretreatment: the masterbatch at the outlet of the kneader is sent into the autoclave, then the antistatic agent is added into the autoclave, stirred for ...

Embodiment 3

[0067] An antistatic degradable film for electronic packaging and a preparation method thereof, wherein the raw material components include the following parts by mass:

[0068] Base resin selection butylene terephthalate 50 parts

[0069] 20 parts polylactic acid

[0070] Strengthening agent chooses 5 parts of ethylene-propylene copolymer

[0071] The coupling agent chooses 3 parts of silane

[0072] Antistatic agents choose siloxane, polyamide and SnO 2 Oxide ratio 1:1:2 5 parts.

[0073] The preparation method is as follows:

[0074] 1) Prepare raw materials for mixing: weigh each component of the raw materials, including matrix resin, reinforcing agent, and coupling agent, put the above raw materials into the mixer, control the stirring rate to 1200r / min, and keep warm at 100°C for 5 minutes;

[0075] 2) Supercritical pretreatment: Send the masterbatch at the outlet of the mixer into the autoclave, then add the antistatic agent into the autoclave, stir for 4 minutes, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com