Preparation of stripping-off liquid rubber/organic clay nano composite material under temperate conditions

A technology of nano-composite materials and liquid rubber, which is applied in the field of exfoliated liquid rubber/organic clay nano-composites, which can solve problems such as harm to the human body and the environment, affect the performance of composite materials, increase dust pollution, etc., and achieve excellent performance and production efficiency High, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

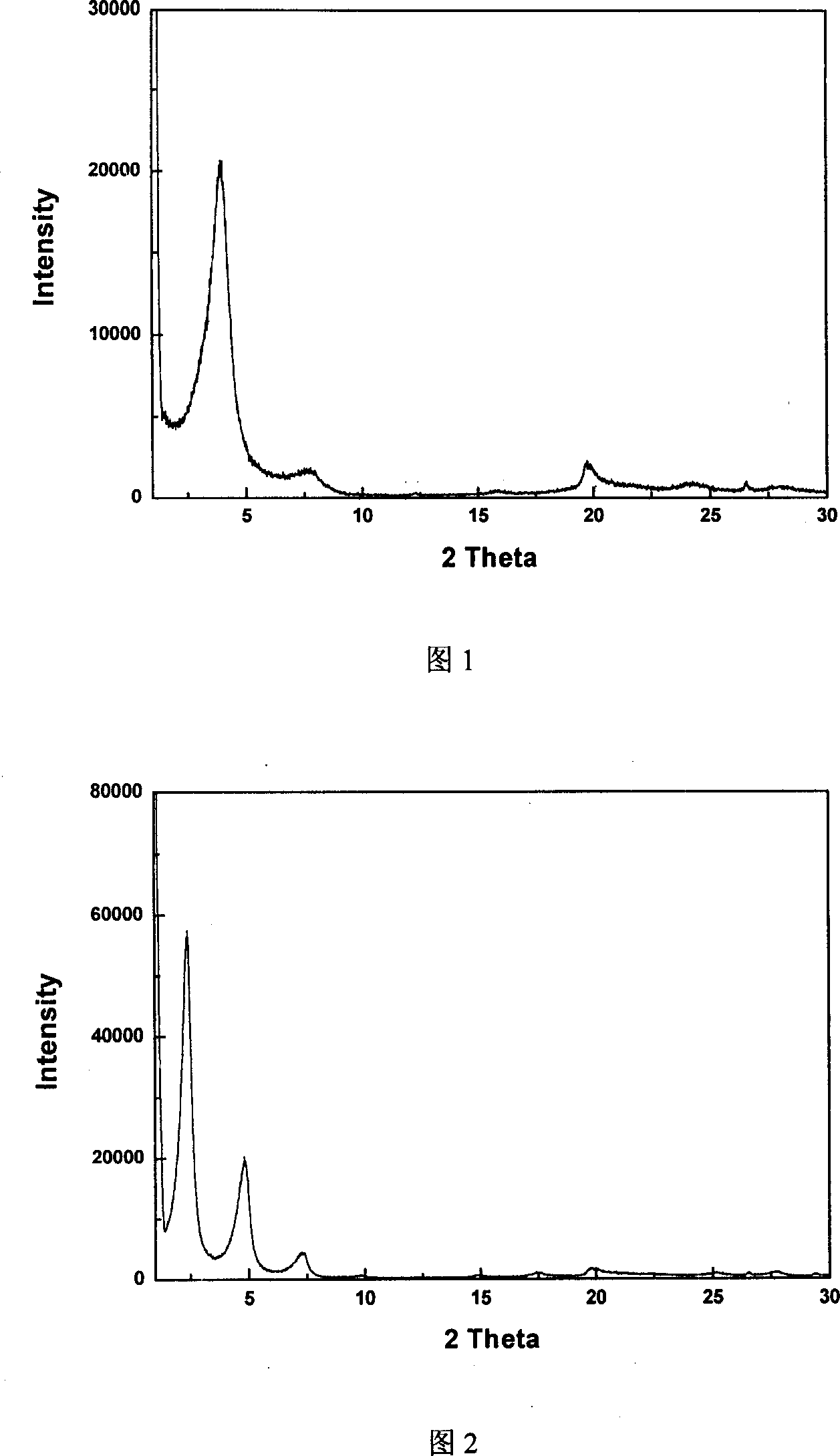

[0032] Preparation of organically modified montmorillonite OM1: Add 10 grams of inorganic montmorillonite with a cation exchange capacity of 80meq / 100g, add 500 grams of water, and stir at high speed for 30 minutes after being uniformly dispersed to obtain a stable suspension; Octadecyltrimethylammonium bromide was dissolved in 100 grams of water to make a solution; the above suspension was heated to 80-90°C, and the above solution was slowly added dropwise, while stirring for 8 hours, naturally cooled to room temperature, and then suction filtered. And washed with water for many times, no bromide ion was detected by using 0.2% silver nitrate solution, and dried to obtain organically modified montmorillonite. Its X-ray diffraction spectrum is shown in Figure 1, and the diffraction peak at 2θ of about 3.97° indicates that the interlayer spacing of the organically modified montmorillonite is 2.3nm.

[0033] 10 grams of this organically modified montmorillonite, and 90 grams of l...

Embodiment 2

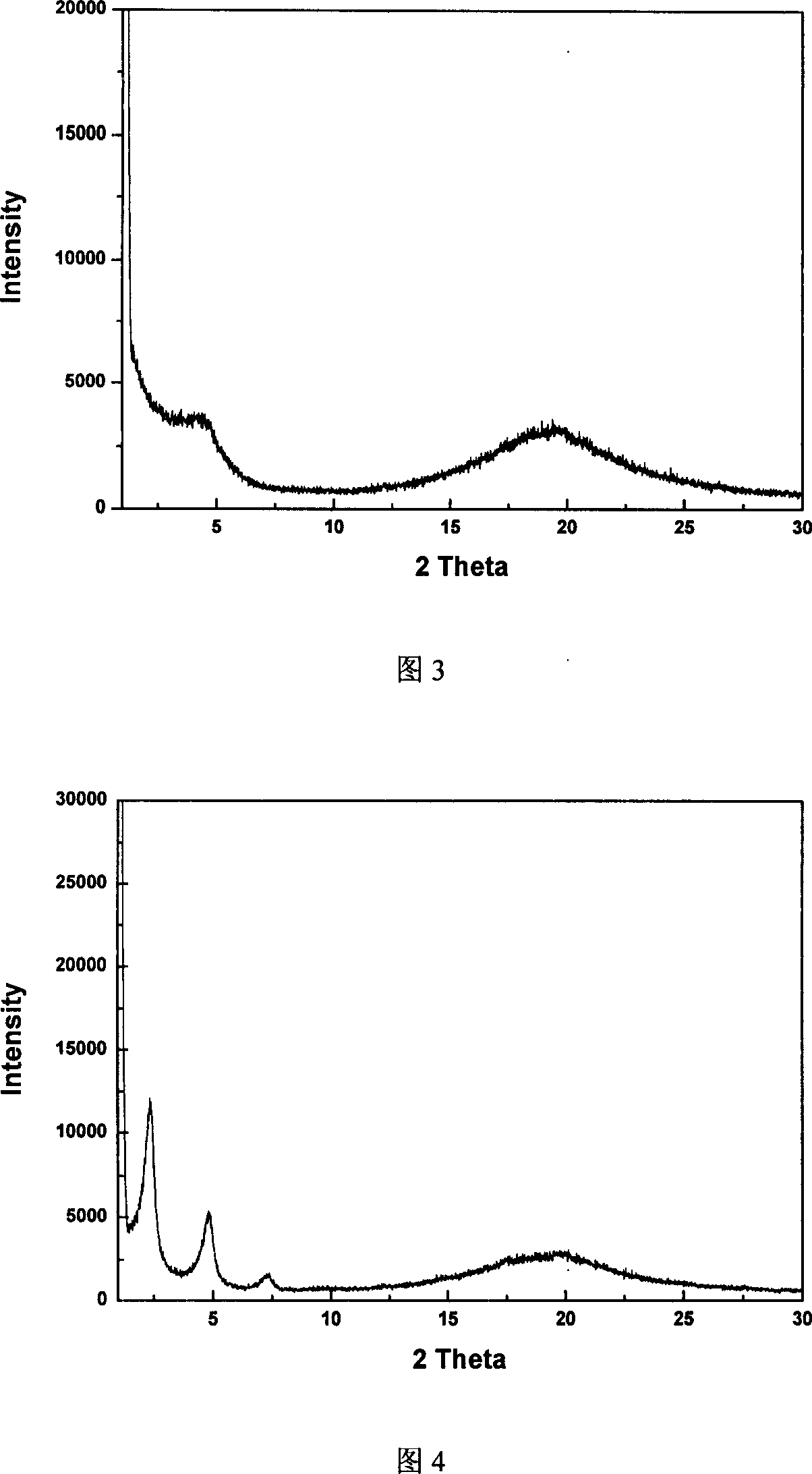

[0035]Preparation of organically modified montmorillonite OM2: Add 10 grams of inorganic montmorillonite with a cation exchange capacity of 80meq / 100g, add 500 grams of water, and stir at high speed for 30 minutes after being uniformly dispersed to obtain a stable suspension; 6.5 grams Dioctadecyldimethylammonium bromide was dissolved in 100 grams of water to make a solution; the above suspension was heated to 80-90°C, and the above solution was slowly added dropwise, while stirring for 8 hours, naturally cooled to room temperature, and then suction filtered , and washed with water several times, with 0.2% silver nitrate solution to detect no bromide ions, and dry to obtain organically modified montmorillonite. Its X-ray diffraction spectrum is shown in Figure 2, and the diffraction peak at 2θ of about 2.49° indicates that the interlayer spacing of the organically modified montmorillonite is 3.6nm.

[0036] 10 grams of this organically modified montmorillonite, and 90 grams of...

Embodiment 3

[0038] Preparation of organically modified montmorillonite OM1: Add 10 grams of inorganic montmorillonite with a cation exchange capacity of 80meq / 100g, add 500 grams of water, and stir at high speed for 30 minutes after being uniformly dispersed to obtain a stable suspension; Octadecyltrimethylammonium bromide was dissolved in 100 grams of water to make a solution; the above suspension was heated to 80-90°C, and the above solution was slowly added dropwise, while stirring for 8 hours, naturally cooled to room temperature, and then suction filtered. And washed with water for many times, no bromide ion was detected by using 0.2% silver nitrate solution, and dried to obtain organically modified montmorillonite. Its X-ray diffraction spectrum is shown in Figure 1, and the diffraction peak at 2θ of about 3.97° indicates that the interlayer spacing of the organically modified montmorillonite is 2.3nm.

[0039] 10 grams of organically modified montmorillonite and 90 grams of liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com