Gap measuring device for the most unfavorable point of elevator landing door

A technology of the most unfavorable point, the measuring device, applied in the direction of measuring devices, instruments, etc., can solve problems such as difficult to meet the needs of measurement, difficult installation of push-pull force gauge, unstable manual operation, etc., to reduce labor intensity and manpower input, measure The process is simple and convenient, and the effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

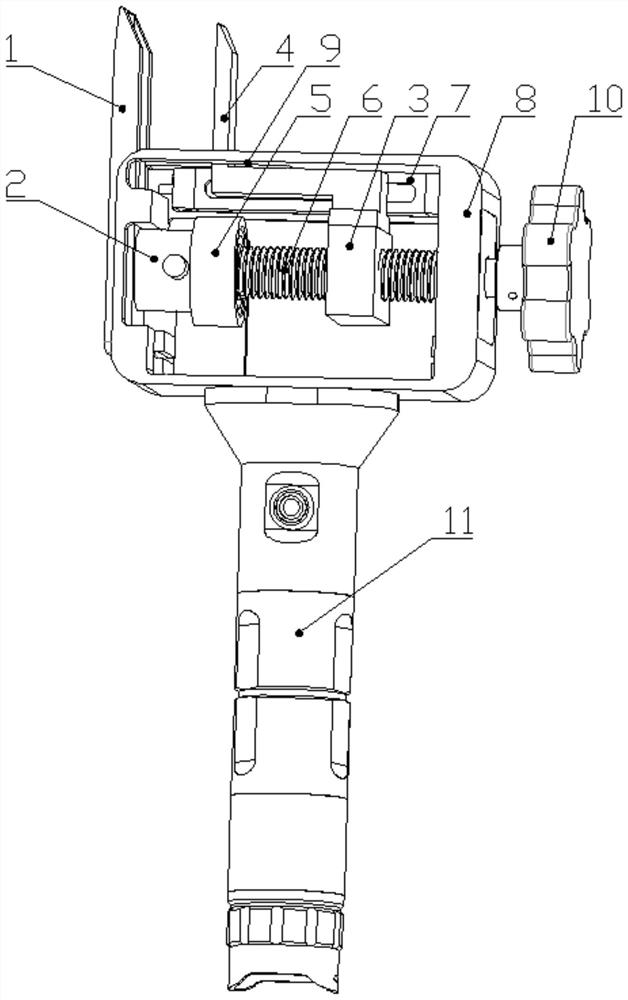

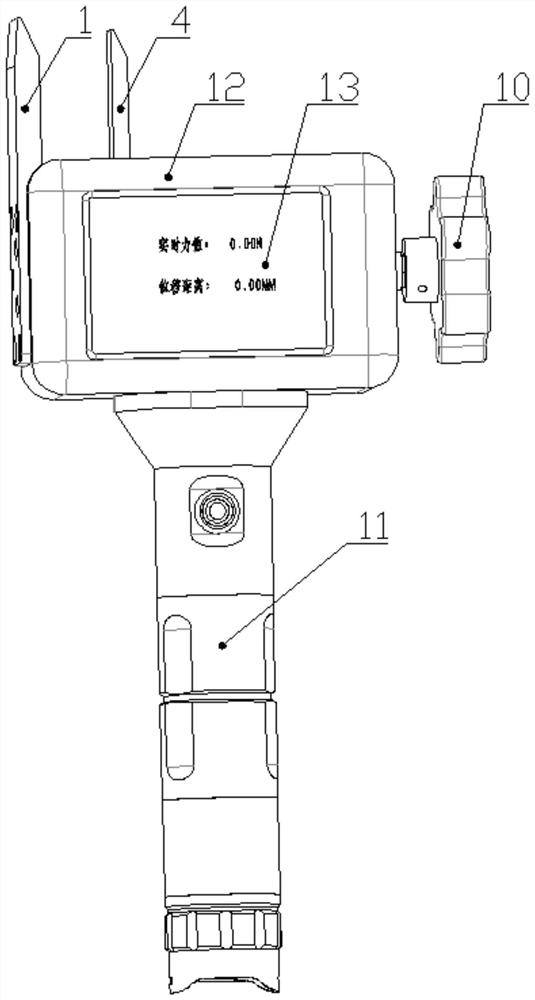

[0023] refer to Figure 1-2 , the present embodiment provides a measuring device for the most unfavorable point gap of an elevator hall door, which includes a lower casing 8 for installing measuring components and an upper casing 12 for installing a display screen 13, and also includes a load cell 2, a left support Seat 1, base 5, screw rod 6, slide table 3, moving plate 4, displacement sensor 7;

[0024] Both sides of the load cell 2 are fixed in the lower casing 8, the left support 1 is installed on the outer surface of the lower casing 8, and the left support 1 is connected to the bottom of the load cell 2, the load cell The top of 2 is connected to the base 5, and the end of the base 5 away from the load cell 2 is connected to the end of the screw rod 6. Specifically, the model of the load cell 2 is WX-CGQ50Kg;

[0025] The screw mandrel 6 is rotatably arranged in the lower casing 8, the screw rod 6 is threadedly connected with the sliding table 3, one end of the moving p...

Embodiment 2

[0029] This embodiment is further optimized on the basis of Embodiment 1. The lower casing 8 is also connected with a handle 11; by setting the handle 11, it can be conveniently held by the measuring personnel, and the portability of the measuring device can be improved, which is convenient for the measuring personnel to use.

Embodiment 3

[0031] The present embodiment is further preferred on the basis of Embodiment 1. The end of the screw mandrel 6 away from the load cell 2 is connected with a handwheel 10; the setting of the handwheel 10 can facilitate the measurement personnel to operate the screw mandrel 6. When in use, Rotating the handwheel 10 can drive the screw mandrel 6 to rotate, thereby driving the slide table 3 and the moving plate 4 to move.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com