Latex powder spray drying tower

A technology of spray drying tower and latex powder, which is applied in the direction of spray evaporation and evaporator accessories, which can solve the problems of poor drying effect and achieve the effects of speeding up the drying process, enhancing the performance of buffering and reset, and strengthening the sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

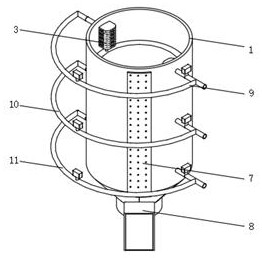

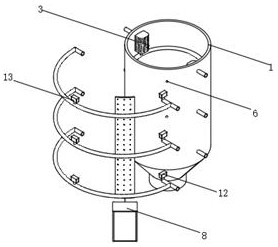

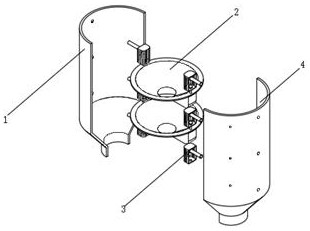

[0038] Such as figure 1 , 2, 3, 4, 7, 8, 9, and 10, a latex powder spray drying tower includes a tower body 1, a cavity 4, a discharge port 5 and a humidity detection head installation hole 6, and the upper end of the tower body 1 is opened There is a cavity 4, the side wall of the tower body 1 is provided with a humidity detection head installation hole 6, a humidity detection head is installed in the humidity detection head installation hole 6, the lower end of the tower body 1 is provided with a discharge port 5, and the cavity 4 The upper part of the cavity is provided with a first-stage vibration-type leaking structure 2, and the middle part of the cavity 4 is provided with a second-stage vibration-type leaking structure 2. The cavity 4 is divided into an upper part by two vibration-type leaking structures 2. cavity, middle cavity and lower cavity, each of the upper cavity, middle cavity and lower cavity is provided with a humidity detection head, and the upper end of th...

Embodiment 2

[0041] Such as figure 1 , 2 , 3, 5, and 6, a vibrating material leakage structure of a latex powder spray drying tower, the vibration type material leakage structure 2 includes a round platform type hopper 201, a through hole 202, a fixed seat 203, a storage bin 204, and a movable rod 206 , the first spring 207, the movable ring 208, the connector 210 and the buffer type sealing cover 211, the cavity inner wall of the cavity 4 is provided with a fixed seat 203, and the upper end of the fixed seat 203 is provided with a placement bin 204, and the placement bin 204 is provided with a Movable bar 206, the shaft of movable bar 206 is sleeved with first spring 207 and movable ring 208, and movable ring 208 is positioned at the first spring 207 upper end, and the upper end of holder 203 is provided with buffer type seal cover 211, and movable bar 206 is from buffering Type sealing cover 211 openings protrude, and the upper end of buffer type sealing cover 211 is placed with round p...

Embodiment 3

[0043] Such as Figure 6 As shown, a reinforced vibration type leaking structure of a latex powder spray drying tower, the vibration type leaking structure 2 also includes an L-shaped block 205 and a second spring 209, and an L-shaped block 205 is arranged in the bin where the bin 204 is placed. The second spring 209 is provided at the stop plate at the lower end of the movable rod 206, and the L-shaped block 205 covers the stop plate of the movable rod 206, and the first spring 207 is located between the L-shaped block 205 and the buffer type sealing cover 211, and the L-shaped block 205 and the buffer type sealing cover 211 The fixed seat 203 is adapted, and the L-shaped block 205 can strengthen the sealing performance of the lower end of the movable rod 206 to prevent dust from falling to the bottom of the movable rod 206. The second spring 209 can enhance the buffering and reset performance of the movable rod 206 to prevent the movable rod 206 from Hitting the fixing seat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com