Filter pressing and washing device for battery material precursor and method adopting device

A battery material and washing device technology, applied in separation methods, chemical instruments and methods, filtration separation, etc., can solve the problems of difficult Na and S washing, uneven washing effect of Na and S, and restriction of production capacity, so as to improve washing Increased production capacity, reduced washing unevenness, and reduced washing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

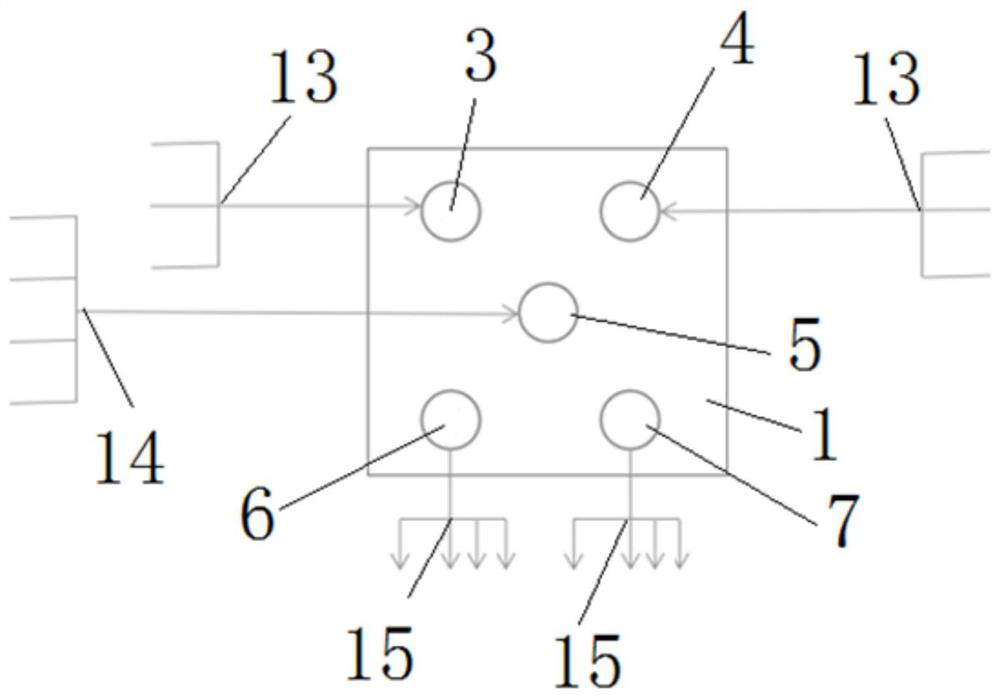

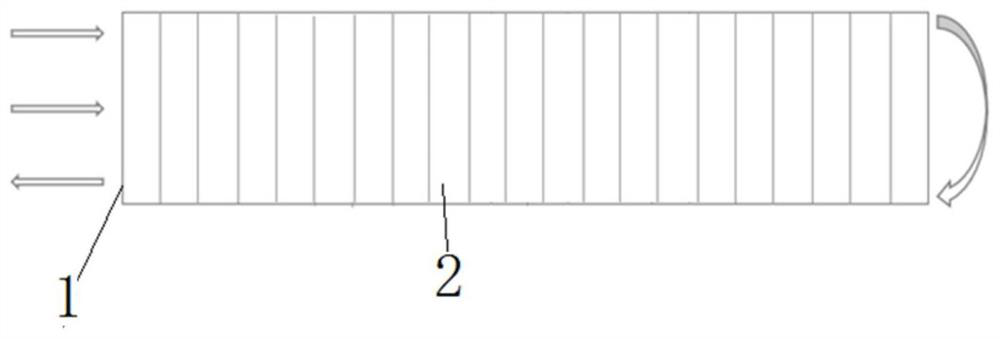

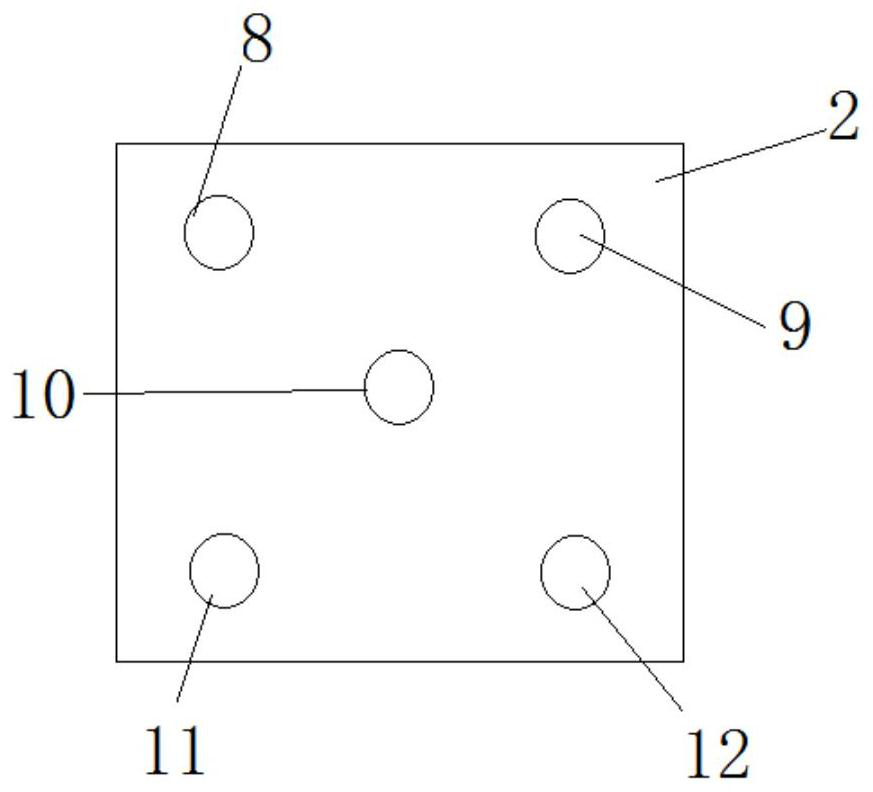

[0043] Battery precursor pressure filter washing method, including:

[0044] (1) Pressure filter: The agonized material is delivered to the third through hole 5 of the pressure filter 1 by the tube, and then sequentially passed through the third through hole 5, the eighth through hole 10 input pressure filter box 1 And the hydraulic device of the filter machine is pressed by pressing the filter plate. At this time, the first through hole 3, the second through hole 4 is closed, and the valve 13 of the four-way tube 13 connected, the filtered mother liquor is removed from On the other side of the pressure filter 1, the ninth through hole 11 is sequentially flowed out, and then the discharge tube is discharged through the mother liquor discharge tube, and the other part is sequentially subjected to the tenth hole 12 from the other side of the pressure filter 1. The five through hole 7 flows out, and then discharged through the mother liquor discharge tube; wherein the apparent materi...

Embodiment 2

[0051] Battery precursor pressure filter washing method, including:

[0052] (1) Pressure filter: The agonized material is delivered to the third through hole 5 of the pressure filter 1 by the tube, and then sequentially passed through the third through hole 5, the eighth through hole 10 input pressure filter box 1 And the hydraulic device of the filter machine is pressed by pressing the filter plate. At this time, the first through hole 3, the second through hole 4 is closed, and the valve 13 of the four-way tube 13 connected, the filtered mother liquor is removed from On the other side of the pressure filter 1, the ninth through hole 11 is sequentially flowed out, and then the discharge tube is discharged through the mother liquor discharge tube, and the other part is sequentially subjected to the tenth hole 12 from the other side of the pressure filter 1. The five through holes 7 flows out, then discharged through the mother liquor discharge tube; wherein the material obtained ...

Embodiment 3

[0058] Battery precursor pressure filter washing method, including:

[0059] (1) Pressure filter: The agonized material is delivered to the third through hole 5 of the pressure filter 1 by the tube, and then sequentially passed through the third through hole 5, the eighth through hole 10 input pressure filter box 1 And the hydraulic device of the filter machine is pressed by pressing the filter plate. At this time, the first through hole 3, the second through hole 4 is closed, and the valve 13 of the four-way tube 13 connected, the filtered mother liquor is removed from On the other side of the pressure filter 1, the ninth through hole 11 is sequentially flowed out, and then the discharge tube is discharged through the mother liquor discharge tube, and the other part is sequentially subjected to the tenth hole 12 from the other side of the pressure filter 1. The five through holes 7 flow, and then discharged through the mother liquor discharge tube; wherein the material obtained b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com