Device used for marking histological embedding box

A technique of embedding cassettes and histology, applied in printing, laser welding equipment, typewriters, etc., can solve the problems of wasting manpower, easily causing confusion, etc., achieving the effect of low cost, avoiding manpower tension, and easy to achieve.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

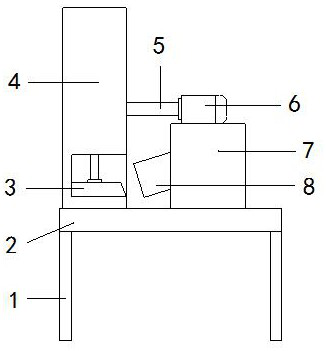

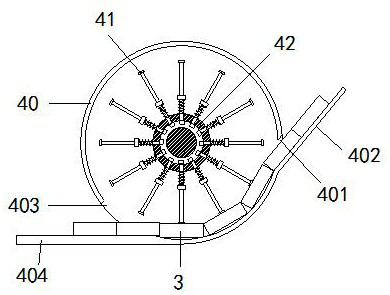

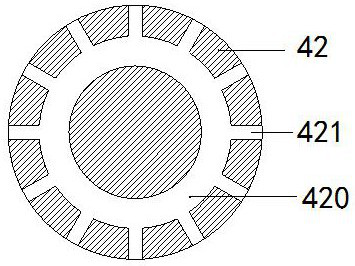

[0026] see Figure 1-4 , the present invention provides a technical scheme of a device for marking histological embedding cassettes: its structure includes a bracket 1, a workbench 2, an embedding cassette 3, a feeding device 4, a rotating shaft 5, a motor 6, a host machine 7, and a laser head 8 , the bottom of the workbench 2 is welded with a bracket 1, the workbench 2 is provided with a host 7, the side of the host 7 is connected with a laser head 8, the top of the host 7 is provided with a motor 6, and the motor 6 passes through Rotating shaft 5 is connected with feeding device 4, and described feeding device 4 is connected on the workbench 2 and is arranged on laser head 8 side, and described feeding device 4 comprises housing 40, elastic rod 41, rotating disk 42, and described housing 40 The bottom is connected to the workbench 2, a turntable 42 is installed in the middle of the casing 40, and evenly distributed elastic rods 41 are installed on the turntable 42, and an in...

Embodiment 2

[0029] see Figure 1-4 , the present invention provides a technical scheme of a device for marking histological embedding cassettes: its structure includes a bracket 1, a workbench 2, an embedding cassette 3, a feeding device 4, a rotating shaft 5, a motor 6, a host machine 7, and a laser head 8 , the bottom of the workbench 2 is welded with a bracket 1, the workbench 2 is provided with a host 7, the side of the host 7 is connected with a laser head 8, the top of the host 7 is provided with a motor 6, and the motor 6 passes through Rotating shaft 5 is connected with feeding device 4, and described feeding device 4 is connected on the workbench 2 and is arranged on laser head 8 side, and described feeding device 4 comprises housing 40, elastic rod 41, rotating disk 42, and described housing 40 The bottom is connected to the workbench 2, a turntable 42 is installed in the middle of the casing 40, and evenly distributed elastic rods 41 are installed on the turntable 42, and an in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com