Comprehensive recycling process for gasification fine slag

A fine slag and process technology, applied in the field of comprehensive recovery and utilization of gasification fine slag, can solve the problems of high recovery cost, environmental pollution, low utilization rate of gasification fine slag, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

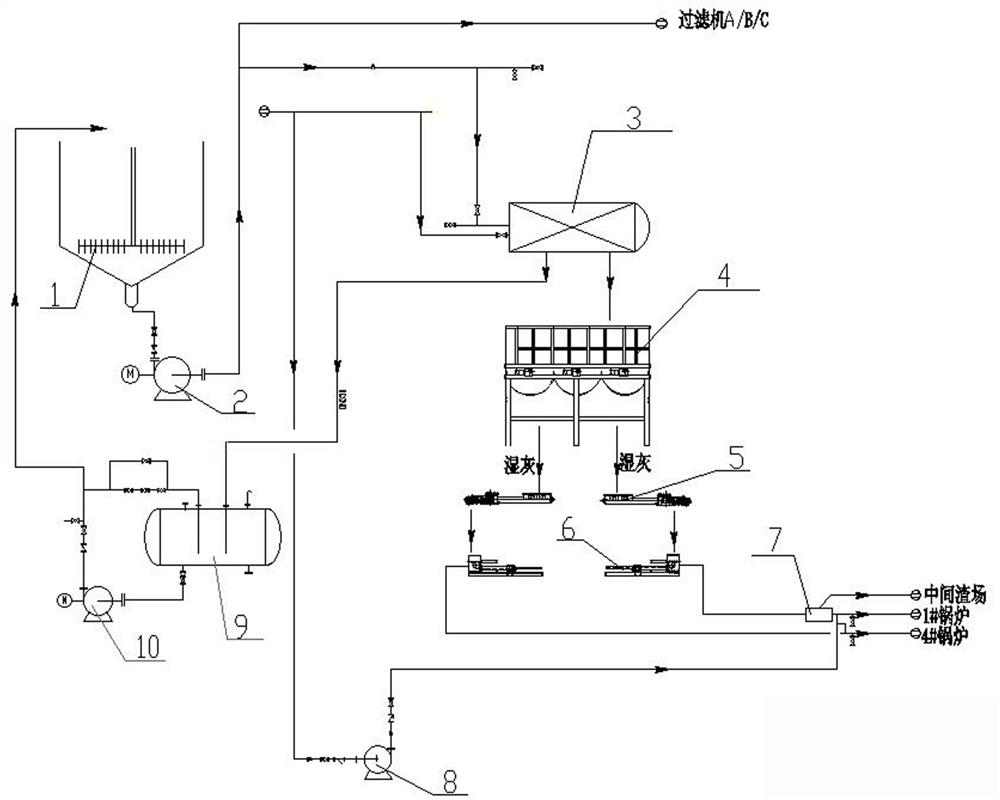

[0021] The gasification fine slag comprehensive recycling process of this embodiment includes the following steps: the gasification fine slag is first sent from the settling tank 1 through the settling tank bottom flow pump 2 to the centrifuge 3 for solid-liquid separation of black water with high solid content, and the centrifuge After the machine 3, it enters the wet ash conveying system, falls into the mixing chamber 4, and carries out stirring treatment, and then controls the outlet to the screw feeder 5 through the hydraulic gate valve, and finally sends it to the compound coal slime after being pressurized by the wet ash conveying pump 6 After the pipeline is sent to the boiler for mixed combustion, the centrifuge 3 filtrate flows into the filtrate tank 9, and the filtrate in the filtrate tank 9 is sent back to the settling tank 1 by the filtrate pump 10 through the pipeline.

[0022] Further, high solid content black water 15wt% is sent to the centrifuge 3 for solid-liqu...

Embodiment 2

[0029] The gasification fine slag comprehensive recycling process of this embodiment includes the following steps: the gasification fine slag is first sent from the settling tank 1 through the settling tank bottom flow pump 2 to the centrifuge 3 for solid-liquid separation of black water with high solid content, and the centrifuge After the machine 3, it enters the wet ash conveying system, falls into the mixing chamber 4, and carries out stirring treatment, and then controls the outlet to the screw feeder 5 through the hydraulic gate valve, and finally sends it to the compound coal slime after being pressurized by the wet ash conveying pump 6 After the pipeline is sent to the boiler for mixed combustion, the centrifuge 3 filtrate flows into the filtrate tank 9, and the filtrate in the filtrate tank 9 is sent back to the settling tank 1 by the filtrate pump 10 through the pipeline.

[0030] Further, high solid content black water 20wt% is sent to the centrifuge 3 for solid-liqu...

Embodiment 3

[0037] The gasification fine slag comprehensive recycling process of this embodiment includes the following steps: the gasification fine slag is first sent from the settling tank 1 through the settling tank bottom flow pump 2 to the centrifuge 3 for solid-liquid separation of black water with high solid content, and the centrifuge After the machine 3, it enters the wet ash conveying system, falls into the mixing chamber 4, and carries out stirring treatment, and then controls the outlet to the screw feeder 5 through the hydraulic gate valve, and finally sends it to the compound coal slime after being pressurized by the wet ash conveying pump 6 After the pipeline is sent to the boiler for mixed combustion, the centrifuge 3 filtrate flows into the filtrate tank 9, and the filtrate in the filtrate tank 9 is sent back to the settling tank 1 by the filtrate pump 10 through the pipeline.

[0038] Further, high solid content black water 25wt% is sent to the centrifuge 3 for solid-liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com