Early strength agent and preparation method thereof

A technology of early-strength agent and catalyst, applied in the field of early-strength agent and its preparation, can solve the problems of improving the early strength of cement, unable to achieve, unable to meet the actual needs of users, etc., and achieve the effect of improving early strength and significant application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

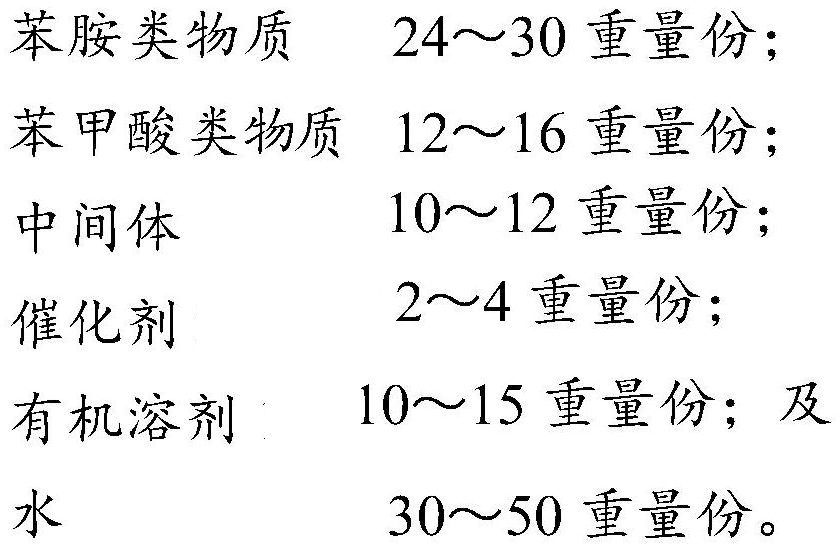

[0051] The embodiment of the present application also provides a preparation method of an early strengthening agent, the preparation method comprising the following steps:

[0052] S100, adding 10-15 parts by weight of organic solvent and 30-50 parts by weight of water into the reaction kettle;

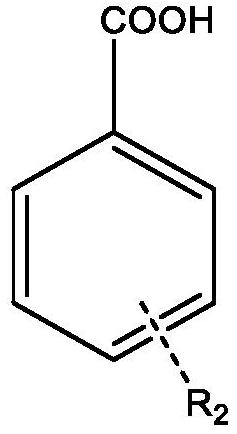

[0053] S200, adding 12 to 16 parts by weight of benzoic acid substances and 1 to 2 parts by weight of catalyst in the reactor;

[0054] S300, adding 10 to 12 parts by weight of the intermediate in the reactor, the intermediate reacts with the benzoic acid to obtain the acid chloride;

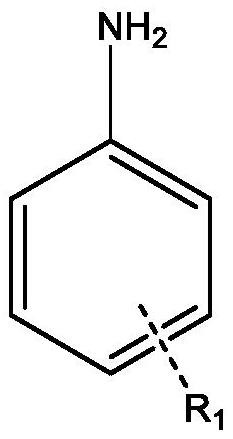

[0055] S400, adding 24 to 30 parts by weight of aniline substances and catalysts into the reaction kettle, acylating the acyl chlorides and aniline substances to prepare the early strength agent, wherein the catalyst added to the reaction kettle includes 2 to 4 parts by weight share.

[0056] In one embodiment, the catalyst includes a first catalyst and a second catalyst, and the first catalyst is dif...

Embodiment 1

[0073] Dissolve 1 part of dimethylformamide in 10 parts of water to make a dimethylformamide solution for use, feed N2 into the reactor, and in parts by weight, add: 12 parts of toluene, 28 parts of water , 12 parts of methyl benzoic acid, adjust the temperature in the reactor to 45°C, after the methyl benzoic acid is completely dissolved, add the prepared dimethylformamide solution dropwise into the reactor, after 5min, in the reactor Add 11 parts of thionyl chloride dropwise to the solution, the time for adding thionyl chloride is 1h, and then keep warm for 2h.

[0074] Adjust the temperature in the reactor to -25°C, add 24 parts of methylaniline and 2 parts of sulfuric acid into the reactor, and react for 4 hours to obtain the accelerator.

Embodiment 2

[0076] Dissolve 1 part of triethylamine in 10 parts of water to make a triethylamine solution for use, feed N2 into the reactor, and in parts by weight, add: 13 parts of ether, 20 parts of water, 14 parts of benzoic acid part, adjust the temperature in the reaction kettle to 40°C, and after the benzoic acid is completely dissolved, add the prepared triethylamine solution dropwise into the reaction kettle, and after 3 minutes, add 12 parts of thionyl chloride dropwise into the reaction kettle, The dropwise addition time of thionyl chloride was 1 h, followed by incubation for 4 h.

[0077] Adjust the temperature in the reactor to -10°C, add 28 parts of ethylaniline and 2 parts of sulfuric acid into the reactor, and react for 6 hours to obtain the accelerator.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com