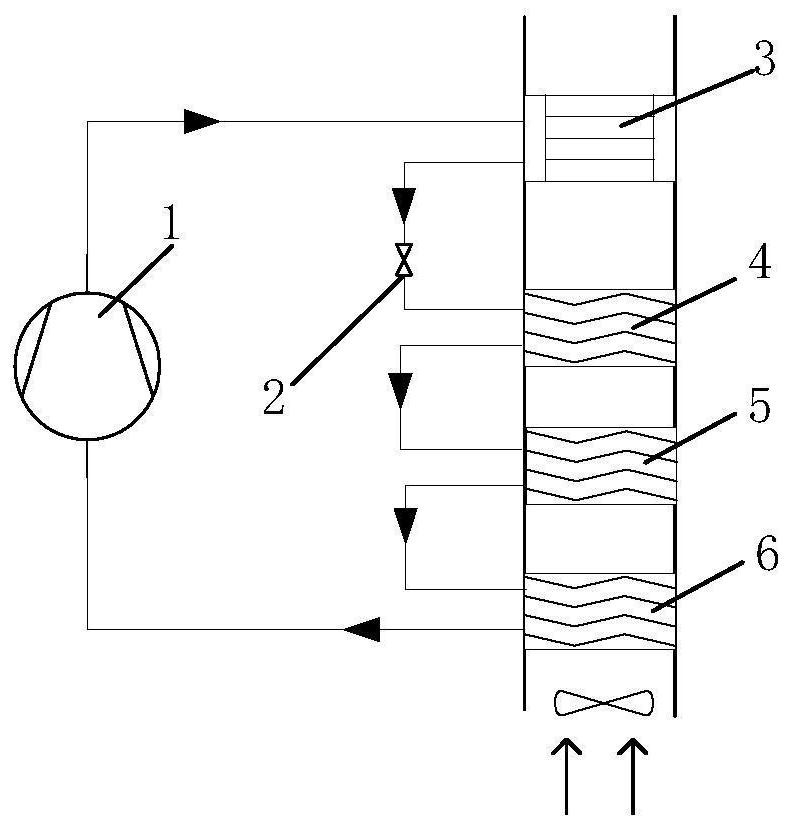

Refrigerant and preparation method thereof, stepped cooling and dehumidifying system, and electrical equipment

A step-down cooling and refrigerant technology, applied in refrigerators, air-conditioning systems, refrigeration and liquefaction, etc., can solve problems such as poor environmental performance and low thermodynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

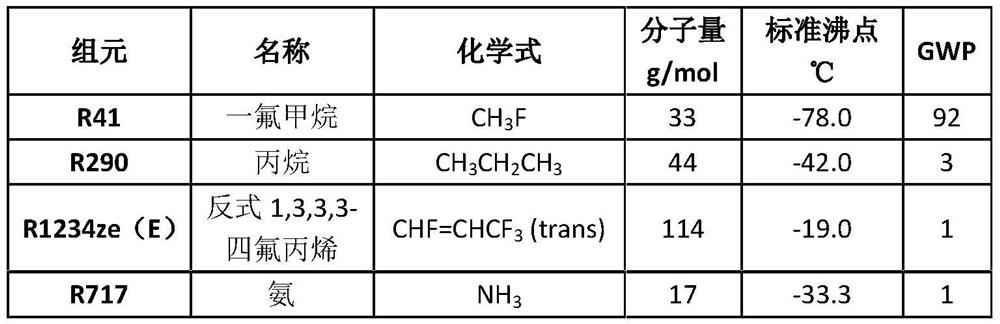

[0031] The three components of fluoromethane (R41), propane (R290), and trans-1,3,3,3-tetrafluoropropene (R1234ze(E)) are mixed in a liquid phase at room temperature in a mass ratio of 5:55:40. Under physical mixing, a refrigerant used in the step-down temperature dehumidification system can be obtained.

Embodiment 2

[0033] The three components of fluoromethane (R41), propane (R290), and trans-1,3,3,3-tetrafluoropropene (R1234ze(E)) are mixed in a liquid phase at room temperature in a mass ratio of 10:30:60. Under physical mixing, a refrigerant used in the step-down temperature dehumidification system can be obtained.

Embodiment 3

[0035] The three components of fluoromethane (R41), propane (R290), and trans-1,3,3,3-tetrafluoropropene (R1234ze(E)) are mixed in a liquid phase at room temperature in a mass ratio of 10:25:65. Under physical mixing, a refrigerant used in the step-down temperature dehumidification system can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com